No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

As industries continue to evolve, the need for efficient material separation has never been more critical. One innovative solution that is making waves across various sectors is the 5-Stack Screen. This advanced screening technology stands out for its ability to enhance separation processes by utilizing multiple stacked screens, allowing for a more precise and effective separation of materials.

In this blog, we will explore five compelling examples of how 5-Stack Screens are revolutionizing material separation in modern industries. By examining these applications, we will highlight the significant advantages offered by this technology, from increased productivity and reduced operational costs to improved environmental sustainability.

Join us as we delve into the future of material separation and discover the potential of 5-Stack Screens in transforming industry standards.

Enhanced material separation techniques are transforming industries by optimizing processes and improving efficiency. According to a report by the International Resource Panel, effective material separation can increase resource recovery rates by up to 50%. This highlights the importance of adopting advanced technologies such as stack screens, which can streamline operations in waste management, recycling, and mining sectors. By efficiently separating materials, industries can minimize waste and ensure that valuable resources are reclaimed, ultimately driving sustainability in a circular economy.

Tip: Implementing regular training sessions for staff on new separation technologies can maximize their potential benefits. Leveraging advanced systems not only boosts productivity but also ensures compliance with environmental regulations. Furthermore, studies show that industries that invest in sophisticated material separation techniques see a return on investment of up to 30% within the first two years.

In addition, improving material separation can lead to significant cost savings. The Waste and Resources Action Programme (WRAP) notes that effective separation can reduce landfill costs by over 40%. By utilizing stack screens, industries can improve their bottom line and contribute positively to environmental conservation efforts. With such compelling data, it’s clear that investing in improved material separation techniques is essential for modern industries aiming for sustainability and profitability.

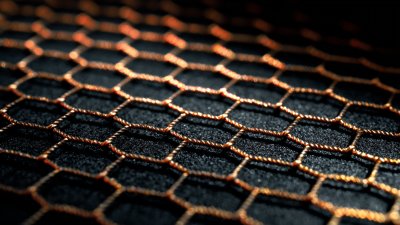

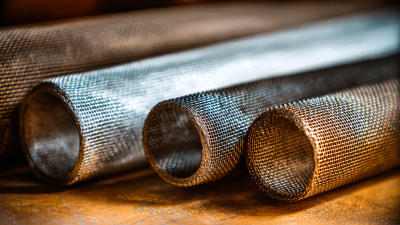

Stack screen technology is emerging as a critical innovation for industries focused on enhancing material separation efficiency. The essential features of stack screens include their multi-layer design, which allows for the separation of finer particles without compromising throughput. This advanced design not only improves the accuracy of separation but also significantly reduces operational downtime, as the technology is less susceptible to clogs compared to traditional screening methods.

Moreover, stack screens can be integrated into various production lines, providing adaptability across sectors such as recycling and mineral processing. Their capability to handle high volumes of materials while maintaining superior performance highlights the importance of maximizing resource recovery and efficiency. As industries shift towards more sustainable practices and seek to optimize productivity, the adoption of stack screen technology represents a strategic investment in operational excellence. Enhanced material separation processes lead to improved overall efficiency, aligning with the goals of modern industrial applications.

In today's industrial landscape, stack screens have emerged as pivotal tools for enhancing material separation across various sectors. Recent industry reports indicate that the global market for separation technology is projected to reach $16 billion by 2025, underscoring the importance of effective material handling and processing in manufacturing and waste management. Stack screens, with their unique design that allows for multiple layers of screening, provide a solution that not only increases efficiency but also significantly reduces operational costs.

One notable application is in mining, where stack screens facilitate the separation of valuable minerals from waste rock. A study by a leading mining technology firm found that incorporating stack screens improved mineral recovery rates by 30%, demonstrating their effectiveness in maximizing output. Furthermore, in the food processing industry, these screens play a crucial role in ensuring product purity by effectively removing contaminants during the production process. As regulations tighten around food safety, the adoption of stack screens is set to rise, promoting both compliance and product quality. With such diverse applications, the continued evolution of stack screens is integral to improving operational efficiencies and sustainability in modern industries.

In the rapidly evolving industrial landscape, the demand for efficient material separation processes has never been higher. Modern stack screening solutions offer a cost-effective means to achieve superior separation outcomes. By utilizing advanced technology, these systems enhance productivity while minimizing waste, allowing industries to streamline operations and reduce operational costs. The flexibility of stack screens, which can process various materials from aggregates to plastics, ensures that businesses can adapt to changing market demands without incurring significant additional expenses.

Moreover, the durability and low maintenance requirements of contemporary stack screening equipment further bolster their cost-effectiveness. Industries investing in these solutions experience not only reduced downtime but also lower replacement costs over time. By optimizing the material separation process, companies can maximize their resource efficiency, yielding higher quality end products. As businesses continue to navigate the challenges of a competitive market, adopting modern stack screening technologies stands out as a strategic investment that enhances both productivity and profitability.

As industries continue to evolve, the need for efficient material separation processes grows increasingly pressing. The future of stack screen design holds exciting potential, as innovations aim to enhance not just functionality but also adaptability across various sectors. Advanced materials and smart technologies are at the forefront, promising screens that can self-adjust to varying material types and densities, ensuring optimal performance with minimal manual intervention.

Incorporating features such as modular designs and AI-driven monitoring systems, modern stack screens are set to revolutionize how businesses approach material separation. By utilizing predictive analytics, these screens can optimize their performance in real-time, thereby reducing waste and improving recovery rates. Furthermore, sustainability remains a key focus, with innovative designs leveraging eco-friendly materials to minimize environmental impact while maximizing efficiency. As these advancements take root, the landscape of material separation will be transformed, paving the way for smarter, cleaner industrial practices.