No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In recent years, the adoption of Fine Mesh products across various industries has seen a significant surge, driven by their superior performance characteristics compared to traditional mesh options. According to a report by MarketsandMarkets, the global mesh market is projected to reach USD 6.2 billion by 2025, with a notable shift towards finer mesh solutions that enhance filtration efficiency and precision.

Fine Mesh offers advantages such as improved particle separation, increased airflow, and enhanced durability, making it a preferred choice in applications ranging from food processing to chemical manufacturing. As industries prioritize quality and innovation, understanding how to leverage Fine Mesh products effectively will be critical for organizations aiming to stay competitive in a rapidly evolving market.

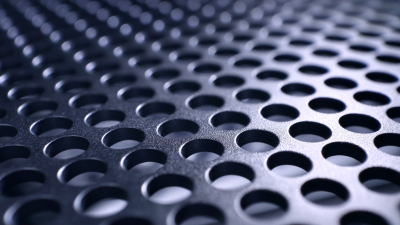

Fine mesh products are taking precedence over traditional mesh solutions, demonstrating significant advantages in various applications. This innovative filtering technology enables improved precision and efficiency, making it ideal for industries ranging from food production to advanced manufacturing. Fine mesh's intricate design allows for enhanced particle separation, ensuring that only the desired materials pass through. This capability is particularly relevant in contexts where contamination must be minimized, such as in pharmaceuticals and biotech sectors.

Fine mesh products are taking precedence over traditional mesh solutions, demonstrating significant advantages in various applications. This innovative filtering technology enables improved precision and efficiency, making it ideal for industries ranging from food production to advanced manufacturing. Fine mesh's intricate design allows for enhanced particle separation, ensuring that only the desired materials pass through. This capability is particularly relevant in contexts where contamination must be minimized, such as in pharmaceuticals and biotech sectors.

In addition to filtration, the versatility of fine mesh can be seen in its use within emerging technologies. As demonstrated by the progress in AI-driven applications, fine mesh concepts are being integrated into systems that require the generation and manipulation of complex structures, highlighting their adaptability. The advancements in utilizing fine mesh in 3D modeling and mesh networks showcase its potential to revolutionize traditional methods. As industries increasingly strive for efficiency and sustainability, fine mesh solutions offer a promising alternative that meets modern demands.

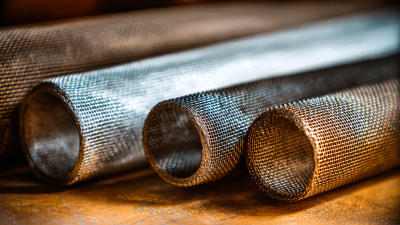

Fine mesh products are gaining traction across various industries due to their superior performance and versatility compared to traditional mesh. The global woven wire mesh market, valued at approximately USD 2.98 billion in 2024, is projected to grow to USD 4.06 billion by 2033, highlighting the increasing demand for advanced materials. Fine mesh provides finer openings, which enhance filtration capabilities, making it ideal for applications in food processing, pharmaceuticals, and environmental protection.

Moreover, the wire mesh decking market is also experiencing significant growth, expected to rise from $1.2 billion in 2024 to $1.8 billion by 2033. The lightweight yet strong characteristics of fine mesh products enable better airflow and visibility while maintaining structural integrity, which is a critical factor for industries like warehousing and logistics. Additionally, innovative manufacturing processes, such as advancements in knitting techniques, are further expanding the usability of fine mesh, offering new finishes and enhanced product durability, thereby solidifying its role across diverse industrial applications.

When comparing fine mesh to traditional mesh products,

durability and performance

emerge as crucial factors influencing their applications. Fine mesh, with its tightly woven structure, offers superior resistance to wear and tear, making it particularly suitable for environments that experience high levels of abrasion or exposure to harsh chemicals. This enhanced durability means that fine mesh products are less likely to degrade over time, resulting in reduced replacement costs and prolonged service life.

Moreover, performance metrics such as airflow and filtration efficiency highlight fine mesh's advantages. Its refined openings provide better air circulation while simultaneously blocking smaller particles that traditional mesh might allow to pass through. This characteristic is especially beneficial in industries such as HVAC and food processing, where maintaining air quality and product purity is essential. By minimizing clogging and maintaining consistent performance, fine mesh ensures optimal operation, which can lead to significant operational savings and improved end-product quality. In contrast, traditional mesh often struggles in these aspects, where its larger openings can compromise both durability and performance in demanding applications.

When selecting the right fine mesh product for your needs, several key factors must be considered. First, the mesh's material plays a crucial role in determining its durability and usability. According to a report by the International Journal of Industrial Mesh Technologies, stainless steel fine mesh exhibits a corrosion resistance rate of up to 85%, making it an ideal choice for environments prone to moisture or chemicals. Alternatively, nylon fine mesh is praised for its lightweight and flexibility, making it suitable for portable applications while maintaining a filtration efficiency of approximately 95% in laboratory settings.

Another critical aspect is the mesh's aperture size, which affects filtration performance. Research from the American Filtration Society indicates that fine mesh products with an aperture size of 100 microns or smaller can trap particles that traditional meshes may allow to pass through. This is particularly vital in industries such as food and beverage, where contamination prevention is paramount. Understanding the specific requirements of your application will help you choose a fine mesh product that not only enhances efficiency but also elevates the overall quality of the final output.

| Feature | Fine Mesh | Traditional Mesh |

|---|---|---|

| Filtration Efficiency | High (up to 99%) | Moderate (60-80%) |

| Durability | Very High | Moderate |

| Maintenance | Low | High |

| Cost | Higher | Lower |

| Applications | Medical, Food Processing, Water Filtration | Construction, Landscaping |

| Versatility | High | Low |

Fine mesh products are often misunderstood, leading to misconceptions about their effectiveness and applications. Many people perceive fine mesh as solely a filtering medium, overlooking its versatility in various industries, including food processing, pharmaceuticals, and chemical manufacturing. According to a report from the Filtration Society, fine mesh can increase efficiency in separation processes by up to 30% compared to traditional mesh due to its ability to capture smaller particles and enhance the purity of end products.

Fine mesh products are often misunderstood, leading to misconceptions about their effectiveness and applications. Many people perceive fine mesh as solely a filtering medium, overlooking its versatility in various industries, including food processing, pharmaceuticals, and chemical manufacturing. According to a report from the Filtration Society, fine mesh can increase efficiency in separation processes by up to 30% compared to traditional mesh due to its ability to capture smaller particles and enhance the purity of end products.

Another common misconception is that fine mesh materials are less durable than their traditional counterparts. In fact, recent studies published in the Journal of Industrial Mesh Technology indicate that high-quality fine mesh can withstand significant pressure and abrasion, making it ideal for demanding applications. For instance, stainless steel fine mesh retains its integrity under extreme conditions, proving to be a cost-effective solution over time by reducing the frequency of replacements and maintenance. These versatile applications highlight the need for a shift in perception towards fine mesh technology, emphasizing its considerable advantages in operational efficiency and product quality.