No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the rapidly evolving landscape of modern industries, the incorporation of innovative technologies is paramount for optimizing processes and enhancing productivity. One such advancement is the PU Dehydrated Screen, which has garnered substantial attention for its efficiency in various applications, particularly in mining and mineral processing industries.

According to a recent market report, the global demand for advanced screening solutions is expected to grow by 8.5% annually, driven by the need for higher operational efficiency and product quality.

PU Dehydrated Screens are instrumental in this growth, offering superior performance in wet and dry processing environments due to their remarkable durability and reduced maintenance costs. With these screens facilitating higher throughput and enhanced separation capabilities, many industries are increasingly integrating them into their production lines, positioning PU Dehydrated Screens as a crucial component for achieving operational excellence in today's competitive market.

According to a recent market report, the global demand for advanced screening solutions is expected to grow by 8.5% annually, driven by the need for higher operational efficiency and product quality.

PU Dehydrated Screens are instrumental in this growth, offering superior performance in wet and dry processing environments due to their remarkable durability and reduced maintenance costs. With these screens facilitating higher throughput and enhanced separation capabilities, many industries are increasingly integrating them into their production lines, positioning PU Dehydrated Screens as a crucial component for achieving operational excellence in today's competitive market.

The evolution of PU dehydrated screens in industrial applications has significantly transformed the efficiency and effectiveness of various processes. Initially developed in the late 20th century, PU screens were primarily utilized for their lightweight and durable properties. According to a report by Grand View Research, the global market for polyurethane screens is expected to grow at a compound annual growth rate (CAGR) of approximately 6% from 2021 to 2028, indicating a sustained demand across multiple sectors, including mining, agriculture, and water treatment.

Over the years, advancements in material technology have led to enhanced designs of PU dehydrated screens, enabling better dewatering performance and extended service life. A study by MarketsandMarkets highlights that industries leveraging these screens experience up to a 30% increase in operational efficiency due to factors such as superior wear resistance and lower maintenance costs. Additionally, PU screens have been integrated with automated systems, allowing for real-time monitoring and improved process controls, further illustrating their significant role in modern industrial applications. This continuous evolution underscores the importance of PU dehydrated screens as a critical component in optimizing industrial operations.

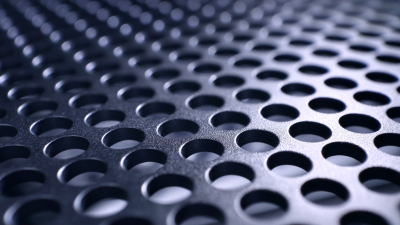

PU dehydrated screens offer several key advantages in material separation processes across various modern industries. Firstly, their exceptional durability and resistance to wear and tear make them ideal for handling abrasive materials. Traditional screens often succumb to damage from harsh substances, which can lead to increased downtime and maintenance costs. In contrast, PU screens maintain their structural integrity longer, thereby enhancing operational efficiency.

Secondly, PU dehydrated screens feature superior flexibility and adaptability, allowing them to perform effectively in diverse separation tasks. Their capability to operate in both wet and dry conditions expands their utility, making them suitable for applications in mining, waste management, and food processing. The screens also exhibit excellent performance in delivering high-capacity throughput while ensuring precise separation of materials, which is critical for industries aiming to optimize their production processes and reduce waste. These attributes collectively underscore the significance of PU dehydrated screens in improving productivity and sustainability in modern industrial operations.

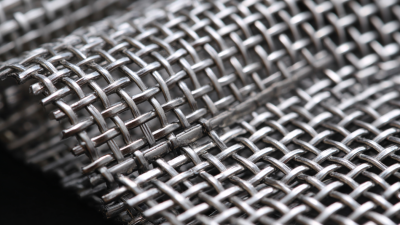

The comparative analysis between PU dehydrated screens and traditional screening methods reveals significant advancements in efficiency and material handling in modern industries. Traditional screening methods, such as woven wire screens, have been standard for decades; however, they often suffer from issues like clogging and lower throughput. According to a report by the Industrial Screen Manufacturers Association, traditional screens can exhibit an average screen life of only 500 hours, resulting in increased downtime and maintenance costs. In contrast, PU dehydrated screens boast a lifespan of up to 2,000 hours, nearly quadrupling the efficiency, which translates to significant cost savings over time.

Moreover, PU dehydrated screens offer superior separation capabilities, especially in fine particle applications. A study published in the Journal of Minerals and Materials Characterization indicates that PU screens have a higher open area than traditional options, improving material flow, and reducing energy consumption by approximately 30%. This enhanced performance makes PU dehydrated screens a preferred choice in various industries, including mining, wastewater treatment, and food processing. As industries strive for greater sustainability and efficiency, PU dehydrated screens set a new standard that traditional screening methods struggle to match.

PU dehydrated screens have revolutionized the operational landscape across various industries by significantly enhancing efficiency while simultaneously reducing costs. The unique properties of polyurethane, such as its durability, flexibility, and resistance to wear and tear, allow for the creation of screens that operate effectively under challenging conditions. This translates to less downtime due to maintenance or replacements, which is critical in sectors like mining, food processing, and water treatment, where continuous operation is key to profitability.

Moreover, these screens optimize the separation processes, leading to higher throughput and better resource recovery. By improving the accuracy of particle size classification, PU dehydrated screens ensure that materials are processed more effectively, minimizing waste and maximizing output. The financial implications are substantial; companies experience reduced operational costs through lower energy consumption and decreased need for manual interventions, further streamlining their processes. Hence, the adoption of PU dehydrated screens not only contributes to operational efficiency but also represents a strategic investment in cost management for modern industries.

The future of Pu dehydrated screen technology is poised for significant advancements, driven by the increasing demand for efficiency and eco-friendliness in various industries. One of the most promising trends is the integration of smart technology into screening processes. These innovative screens can incorporate sensors and IoT capabilities, enabling real-time monitoring and data analysis. This will help operators optimize their processes, reduce downtime, and increase the overall lifespan of equipment.

Another key trend is the development of advanced materials that enhance the performance of Pu dehydrated screens. Researchers are exploring composites that are not only more durable but also lighter and more resistant to wear and tear. These materials can withstand harsher environments, making them more suitable for a variety of applications, from food processing to mining. Additionally, the focus on sustainability will lead to the creation of screens that are recyclable and energy-efficient, aligning with global efforts to reduce environmental impact. As industries continue to evolve, the innovations in Pu dehydrated screen technology will play a critical role in shaping efficient, sustainable operations.