No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

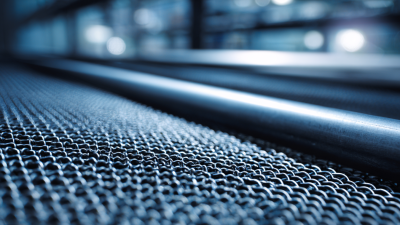

In the realm of industrial applications, the choice of materials plays a critical role in ensuring efficiency and effectiveness. Among the various options available, Fine Mesh Metals stand out due to their unique properties and versatile uses. These finely woven metals are engineered to enhance performance in a wide range of sectors, from filtration to measurement, and they offer significant advantages that can lead to improved operational outcomes.

As industries continue to seek innovative solutions that maximize productivity and quality while minimizing waste and costs, the adoption of Fine Mesh Metals is becoming increasingly prevalent. Their ability to provide precise filtration, durability, and lightweight characteristics makes them an essential material for various applications. In this article, we will explore the top five benefits of using Fine Mesh Metals in industrial practices, highlighting why they are a preferred choice for many manufacturers and engineers aiming for excellence in their operations.

Fine mesh metals have emerged as a pivotal component in various industrial applications, particularly in enhancing filtration efficiency. One of the primary advantages of fine mesh metals is their ability to provide superior filtration, which is essential in environments requiring high purity standards. The small openings in fine mesh allow for the effective separation of particles, thereby improving the quality of the end product while minimizing contamination.

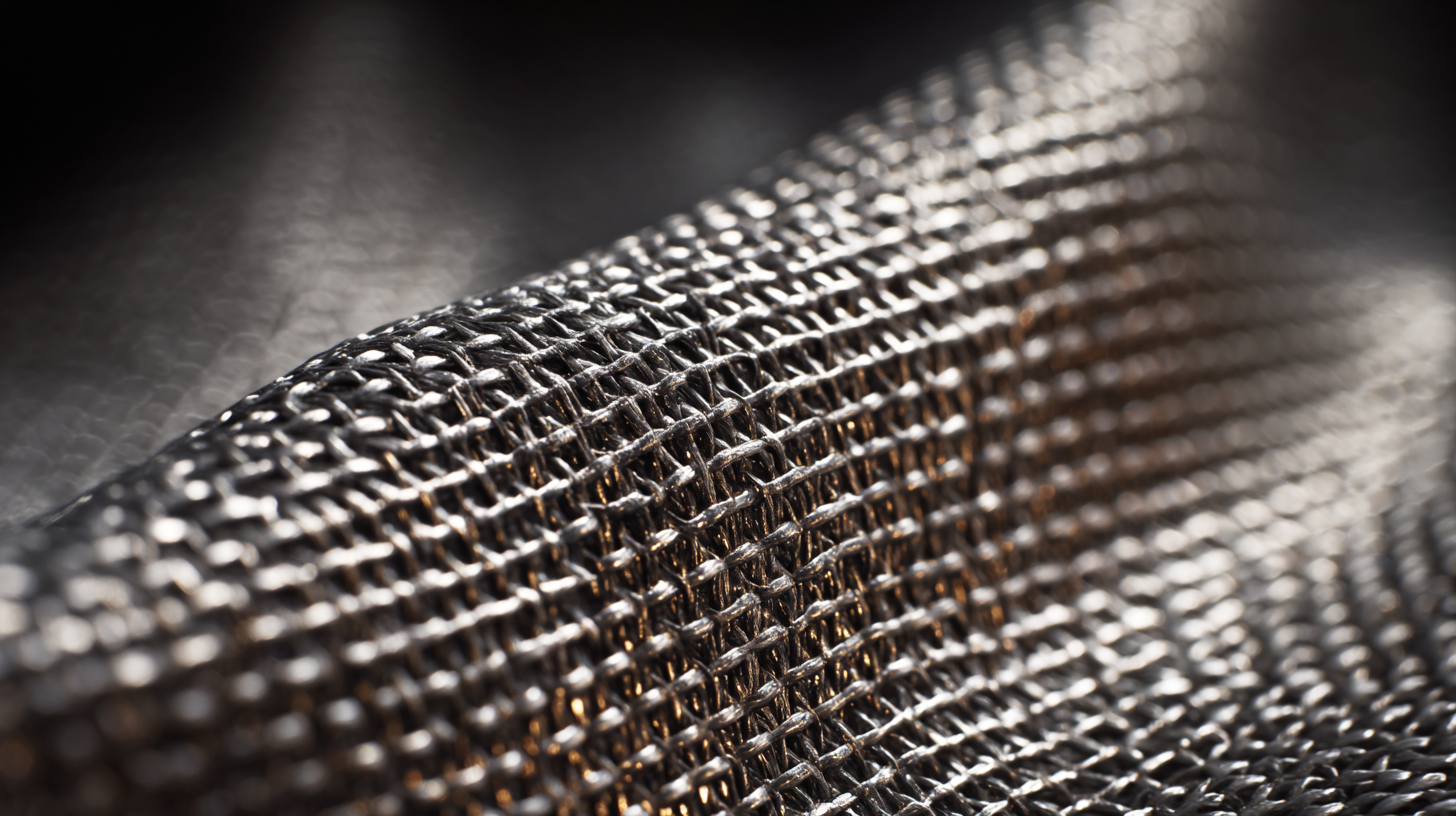

Moreover, recent advancements in eco-friendly wire mesh configurations signify a shift towards sustainable practices in industrial settings. By employing lightweight aggregate concrete (LWAC) combined with various steel wire mesh types, studies have shown significant enhancements in mechanical properties, contributing to the durability and longevity of structures. This development not only supports the efforts for greener construction practices but also underscores the potential of fine mesh metals in optimizing material performance, making them a valuable asset across multiple sectors.

Moreover, recent advancements in eco-friendly wire mesh configurations signify a shift towards sustainable practices in industrial settings. By employing lightweight aggregate concrete (LWAC) combined with various steel wire mesh types, studies have shown significant enhancements in mechanical properties, contributing to the durability and longevity of structures. This development not only supports the efforts for greener construction practices but also underscores the potential of fine mesh metals in optimizing material performance, making them a valuable asset across multiple sectors.

Fine mesh metals offer significant advantages in industrial environments, particularly concerning chemical resistance. In sectors where exposure to harsh chemicals is routine, using fine mesh metals can prevent degradation and extend equipment life. These materials resist corrosion and abrasion, ensuring that filtration systems and containment barriers maintain their integrity even when faced with aggressive substances.

Additionally, their ability to withstand various chemical reactions promotes safer operational conditions. The enhanced resilience of fine mesh metals minimizes the risk of failure, reducing downtime and maintenance costs. This reliability is crucial in industries such as pharmaceuticals, chemical processing, and food and beverage, where product purity and safety are paramount. By incorporating fine mesh metals, manufacturers can ensure that their processes run smoothly while effectively managing the challenges posed by harsh chemicals.

| Benefit | Description | Applications | Material Types |

|---|---|---|---|

| Chemical Resistance | Fine mesh metals resist corrosion from aggressive chemical environments, prolonging product life. | Chemical processing, wastewater treatment | Stainless steel, Hastelloy |

| Enhanced Filtration | Provides superior filtration with a fine mesh that captures small particles. | Oil and gas, pharmaceutical industry | Nickel alloy, titanium |

| Durability | Designed for extreme conditions, offering high tensile strength and durability. | Mining, construction | Carbon steel, aluminum |

| Customizability | Can be engineered to specific requirements, including size and mesh opening. | Food processing, beverage industry | Brass, bronze |

| Weight Efficiency | Lightweight designs reduce the overall weight of structures without sacrificing strength. | Aerospace, automotive | Aluminum alloys, titanium |

Fine mesh metals have transformed numerous industrial applications by significantly enhancing strength and durability in various products. One of the primary advantages of using these materials is their ability to withstand extreme conditions, such as high temperatures, corrosive environments, and heavy mechanical stress. Unlike traditional materials, fine mesh metals are engineered to disperse these stresses uniformly, reducing the likelihood of failure over time. This added resilience ensures that equipment maintains its functionality and integrity, even under demanding circumstances.

Furthermore, the increased durability of fine mesh metals contributes to lower maintenance costs and longer service life for industrial machinery and components. By minimizing wear and tear, these materials decrease the frequency of replacements and repairs, leading to substantial cost savings in the long run. Industries that prioritize longevity and reliability, such as aerospace, automotive, and chemical processing, benefit greatly from incorporating fine mesh metals, ensuring they can meet their production standards without sacrificing quality.

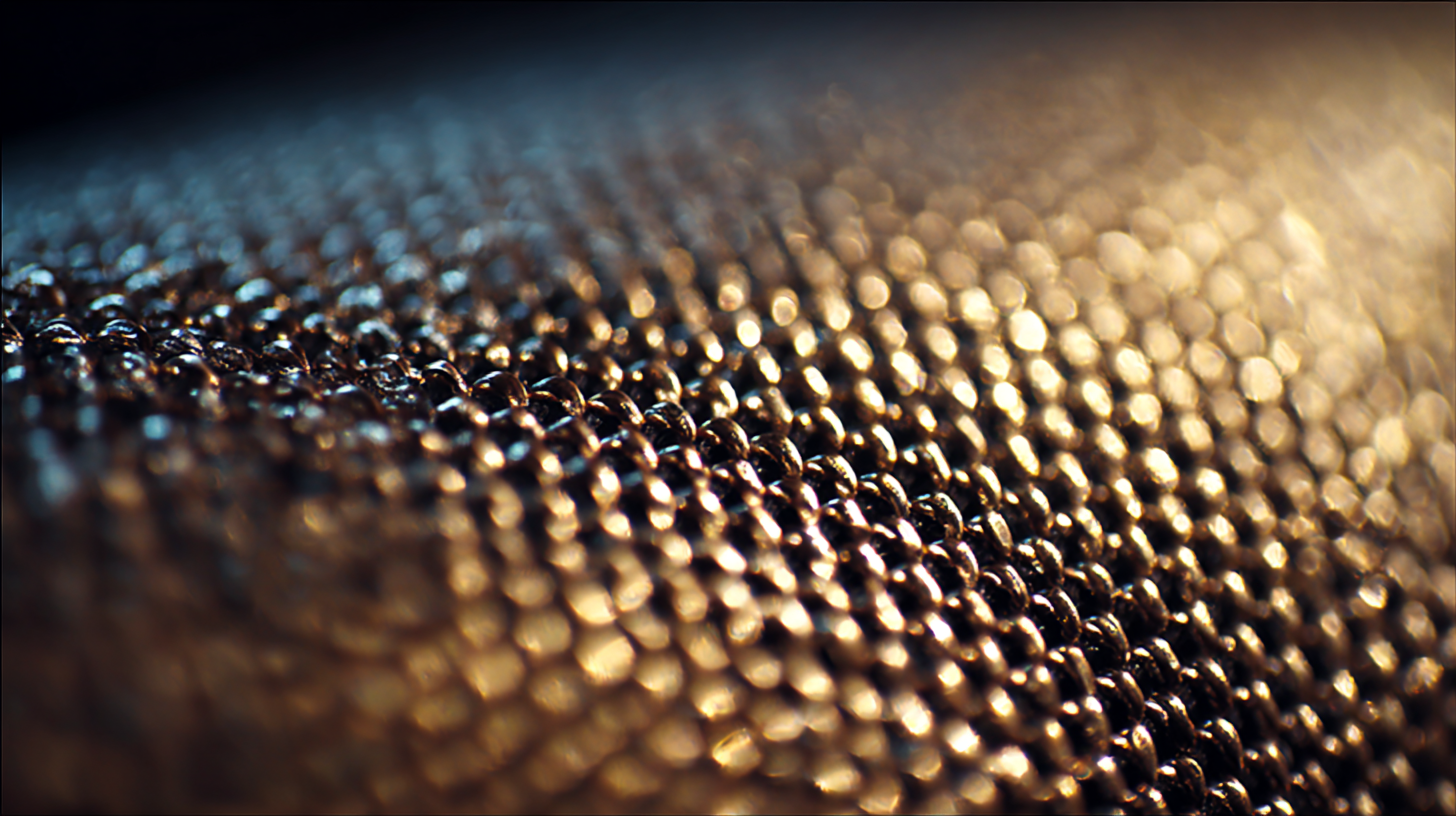

Fine mesh metals have found versatile applications across various industries, owing to their unique properties and benefits. In the pharmaceutical sector, for instance, they are indispensable for filtration processes. Their capability to effectively separate particles at a microscopic level ensures that drugs are free from contamination, thus maintaining the integrity and safety of pharmaceutical products. Additionally, the use of fine mesh in this industry helps in optimizing processes like fluid dynamics, which is crucial for scaling operations.

In the aerospace and automotive industries, fine mesh metals play a critical role in enhancing the performance and durability of components. The lightweight yet strong nature of these materials makes them ideal for manufacturing parts that require both strength and minimal weight for fuel efficiency. Furthermore, they are frequently employed in the design of noise and vibration dampening systems, contributing to overall passenger comfort and vehicle performance. With their ability to withstand extreme conditions, fine mesh metals are poised to continue transforming industrial applications across diverse fields, driving innovation and efficiency.

Fine mesh metals are increasingly recognized for their cost-effectiveness and sustainability in various industrial applications. Industries are shifting toward these materials due to their ability to significantly reduce operational costs. According to a recent report by Market Research Future, the global fine mesh metal market is projected to grow at a compound annual growth rate (CAGR) of 5.8% between 2022 and 2028. This growth highlights a trend where companies are leveraging fine mesh metals not only for their functionality but also for their economic advantages.

One of the prominent sustainability benefits of fine mesh metals is their recyclable nature. Materials like stainless steel and aluminum can be recycled multiple times without losing their properties, contributing to a circular economy. A study conducted by the International Institute for Sustainable Development indicates that using recyclable materials can lead to a reduction of up to 70% in energy consumption compared to virgin materials. Furthermore, fine mesh metals, due to their efficient use in filtration and separation processes, can minimize waste, enhancing a company's commitment to environmental stewardship. As industries continue to adopt these innovative materials, the dual benefits of cost savings and sustainability are becoming increasingly compelling in their operational strategies.