No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In 2026, the use of Fine Mesh Screens has gained significant attention. Experts believe they offer unique advantages across various industries. John Anderson, a leading authority in filtration technology, stated, "Fine Mesh Screens are redefining efficiency and quality in manufacturing processes." His insight highlights the growing importance of these screens.

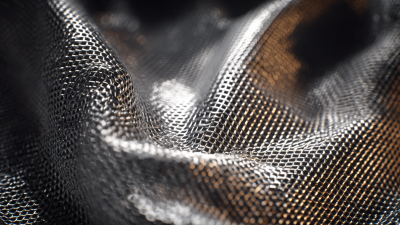

Fine Mesh Screens provide precise filtration. They can separate smaller particles, ensuring cleaner outputs in products. Their application ranges from food processing to pharmaceuticals. Manufacturers are witnessing enhanced performance with these screens. The durability of these materials also plays a key role. They withstand harsh conditions while maintaining quality.

However, there are challenges. Some users may underestimate the importance of proper maintenance. Neglecting regular cleaning can lead to reduced efficiency. This is a critical area for reflection. As we explore the benefits further, it’s essential to acknowledge both the advantages and potential drawbacks. Fine Mesh Screens are revolutionary, yet they require responsible usage to maximize their benefits.

Fine mesh screens have become indispensable for filtration processes in various industries by 2026. A recent report indicated that fine mesh screens can reduce particle contamination by 98%. This improvement in efficiency can lead to higher product quality. For example, in water treatment, fine mesh screens effectively remove tiny debris and sediments. They ensure that the final output is crystal clear and safe.

The versatility of fine mesh screens is evident in their applications. These screens are used in pharmaceuticals, chemicals, and food processing. According to industry research, fine mesh filtration can save companies up to 30% in material costs due to less waste. However, some challenges exist. Many users report difficulties in cleaning fine mesh screens, leading to longer maintenance times. Additionally, the initial investment can be high for some businesses.

It is crucial to recognize that while fine mesh screens offer numerous benefits, they aren't a one-size-fits-all solution. Users must assess specific needs and operational considerations. For instance, in high-pressure environments, screen durability becomes vital. The effectiveness of fine mesh screens can vary greatly depending on the application. Balancing these factors will ultimately drive success in filtration processes.

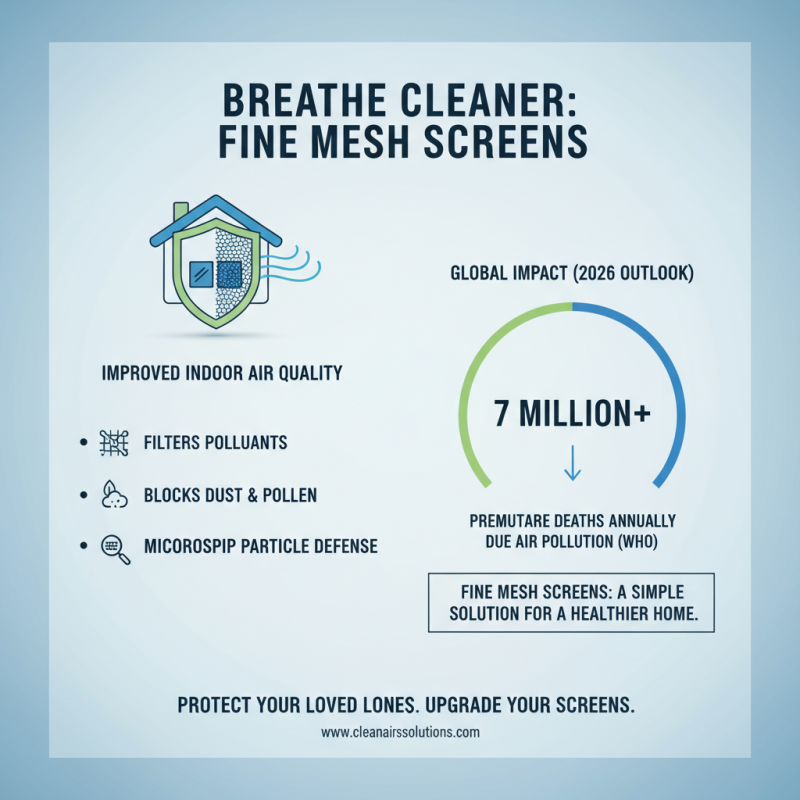

Fine mesh screens are becoming increasingly important for enhancing air quality in our homes and workplaces. As we move closer to 2026, research from the World Health Organization highlights that air pollution causes over 7 million premature deaths annually. Fine mesh screens can significantly reduce the infiltration of airborne pollutants. They filter dust, pollen, and even microscopic particles, contributing to healthier indoor environments.

Implementing fine mesh screens can dramatically improve your space. They block harmful substances while allowing fresh air to circulate. A recent study found that installing these screens can lead to a 30% reduction in indoor particulate matter. This is crucial for individuals with respiratory issues. However, not all fine mesh screens are created equal. Some may not perform as expected, leading to potential air quality concerns.

**Tips:** Regularly check and maintain your screens. Ensure they are fitted properly to maximize efficiency. Consider seasonal changes. For example, pollen counts can increase during spring, making timely screen updates vital. Fine mesh screens serve as a barrier against unwanted allergens. Remember, even the best screens need upkeep. Clean them periodically to avoid clogs and ensure they function effectively.

In 2026, homeowners increasingly recognize the importance of fine mesh screens for pest control. These screens offer a barrier against insects while allowing airflow. According to a recent pest management report, homes with fine mesh screens experience a 30% reduction in pest-related issues. This reduction directly impacts comfort and health.

While fine mesh screens are effective, they are not foolproof. Some pests, like mosquitoes, can find ways to bypass these barriers. Regular maintenance is crucial. Homeowners should inspect screens for holes or wear. The cost-efficiency of these screens is worth noting. An investment in fine mesh can save homeowners up to 40% in pest control services over the year.

Using fine mesh screens also promotes a greener approach to pest management. Less reliance on chemical treatments reduces environmental impact. However, achieving complete pest control requires a holistic strategy. Homeowners may need to consider additional solutions alongside screens. Finding the right balance is essential for optimal results.

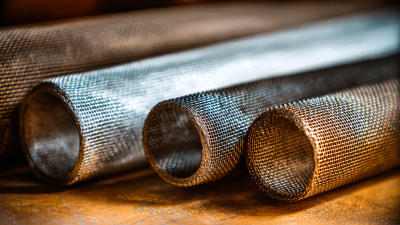

Fine mesh screens have gained popularity due to their durability and ease of maintenance. These screens are often made from high-quality materials, which can withstand various environmental factors. They resist rust and damage from sunlight. This resilience means they last much longer than traditional screens. Users often find that they require less frequent replacement.

Maintenance of fine mesh screens in 2026 is straightforward. Cleaning is typically simple; a light rinse usually suffices. However, some users might overlook hard-to-reach areas where dirt can accumulate. Regular checks can prevent buildup and prolong screen life. It’s crucial to keep an eye on the fittings as well. If neglected, small issues might become larger over time.

While fine mesh screens offer numerous benefits, challenges can arise. Occasionally, the mesh might tear if exposed to harsh conditions. Users may need to consider climate factors when selecting these screens. Taking care ensures they perform effectively and maintain visual appeal. Balancing durability and practical maintenance is key for long-term satisfaction.

In 2026, fine mesh screens find versatile applications across many industries. These screens serve critical functions in manufacturing, food processing, and environmental protection. They effectively filter particles as small as 10 microns, enhancing product purity. According to a report from industry analysts, the fine mesh screen market is projected to grow by 7% annually. This growth indicates a rising demand for filtration solutions.

In the food processing sector, fine mesh screens are crucial for ensuring health and safety. They help in removing contaminants from liquids, maintaining product quality. A recent survey revealed that 80% of food manufacturers prioritize filtration efficiency. Additionally, in construction and recycling, fine mesh screens separate materials without losing valuable resources. However, the reliance on these screens raises concerns. Quality control can be challenging, and not all screens meet industry standards.

Innovation is needed within the fine mesh technology space. Some screens are prone to wear and tear, affecting their performance. As industries push for sustainability, the material selection for fine mesh screens requires careful consideration. Manufacturers must address these issues to fully harness their potential in various applications.