No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the competitive construction industry, the choice of materials can significantly influence project efficiency and longevity. One innovative solution that has gained traction in recent years is the MDI PU screen panel. According to a report by ResearchAndMarkets, the global construction materials market is projected to expand at a CAGR of 7.2% from 2021 to 2026, driven by an increasing demand for sustainable and high-performance building materials. MDI PU screen panels, renowned for their versatility and durability, stand out as a valuable addition to this growing market.

The unique properties of MDI PU screen panels, such as excellent resistance to environmental factors and their lightweight nature, make them particularly suited for various construction applications. The American Concrete Institute (ACI) emphasizes the importance of adopting innovative materials to enhance structural performance and sustainability in construction projects. With an increase in infrastructure investments and a heightened focus on eco-friendly materials, MDI PU screen panels offer construction professionals a reliable option that aligns with modern building demands. By exploring the top ten benefits of these panels, stakeholders can better understand their role in enhancing project outcomes while meeting sustainability goals.

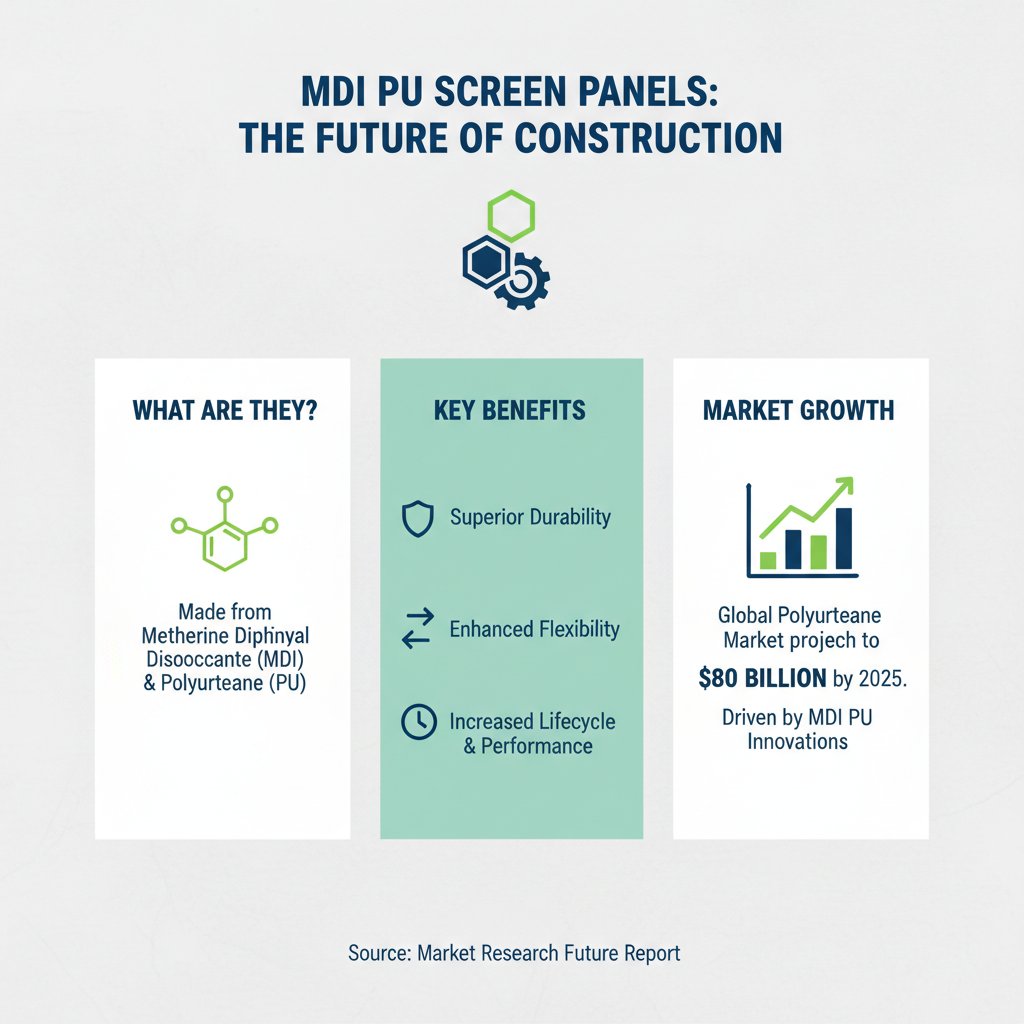

MDI PU screen panels, made from methylene diphenyl diisocyanate (MDI) and polyurethane (PU), are becoming an essential component in modern construction projects. These panels offer superior durability and flexibility compared to traditional materials. According to a report from Market Research Future, the global polyurethane market is projected to reach $80 billion by 2025, driven primarily by innovations in materials like MDI PU, which increase lifecycle and performance.

One of the critical advantages of MDI PU screen panels is their resistance to environmental factors such as moisture and UV radiation. A report by TechSci Research highlights that the use of advanced materials such as MDI PU is driving growth in the construction sector, with the demand expected to rise by 6.9% annually through 2026. This resilience not only extends the lifespan of the panels but also reduces maintenance costs, providing long-term economic benefits for construction projects. Additionally, the lightweight nature of MDI PU screen panels facilitates easier handling and installation, optimizing labor efficiency on job sites. The integration of these panels can significantly enhance the overall structural integrity of construction projects, making them a strategic choice for modern builders.

MDI PU screen panels have become a game-changer in construction projects, offering several key advantages that enhance efficiency and durability. One of the primary benefits is their exceptional strength-to-weight ratio, which allows for easier handling and installation without compromising structural integrity. This lightweight nature not only speeds up the assembly process but also reduces the overall load on support systems, making it a favorite choice among builders.

Additionally, MDI PU screen panels are renowned for their superior resistance to environmental factors, including moisture and chemical exposure. This resilience translates to extended service life, reducing the frequency and costs associated with maintenance and replacement. Furthermore, these panels are designed with energy efficiency in mind, contributing to reduced energy consumption in buildings. Their excellent thermal insulation properties help maintain stable indoor temperatures, resulting in lower heating and cooling costs for occupants. These advantages solidify the position of MDI PU screen panels as a versatile and practical solution in modern construction practices.

| Benefit | Description | Impact on Construction |

|---|---|---|

| Durability | MDI PU panels are highly resistant to wear and tear, ensuring long-lasting performance. | Reduced need for replacements, saving time and costs over the project lifecycle. |

| Lightweight | These panels are lighter than traditional concrete options, making them easier to handle. | Lower labor costs and improved safety during transportation and installation. |

| Water Resistance | MDI PU panels are inherently resistant to water damage and corrosion. | Enhanced longevity in damp environments, reducing the risk of structural issues. |

| Thermal Insulation | Superior insulation properties help maintain optimal temperatures. | Lower energy costs for heating and cooling systems in buildings. |

| Customization | Panels can be tailored in size, color, and shape according to project requirements. | Greater flexibility in design, enhancing aesthetic appeal of constructions. |

| Cost-Efficiency | Lower material and labor costs compared to traditional materials. | Overall savings throughout the project, enabling better budget management. |

| Ease of Installation | Quick and straightforward installation process reduces project timelines. | Minimizes downtime, allowing faster completion of projects. |

| Sustainability | MDI PU is often made from eco-friendly materials, contributing to green building efforts. | Support for sustainable construction practices attracting eco-conscious clients. |

| Impact Resistance | These panels can withstand significant impacts, such as hail and debris. | Increased safety and reduced maintenance in adverse weather conditions. |

MDI PU screen panels, known for their exceptional durability and longevity, are rapidly becoming a preferred choice in construction projects. According to a report by the Construction Industry Institute, materials with enhanced durability can reduce the frequency of replacements and maintenance by up to 30%. This translates to significant cost savings over the life cycle of a construction project, making MDI PU screen panels a wise investment for builders.

In addition, MDI PU screen panels exhibit superior resistance to environmental factors such as moisture, UV radiation, and chemical exposure. A study published in the Journal of Construction Materials highlighted that MDI-based polyurethane products maintain their structural integrity and performance even after prolonged exposure to harsh conditions. This resilience not only contributes to the longevity of the panels but also ensures safety and reliability in structural applications. By choosing MDI PU screen panels, construction professionals can ensure that their projects are built to withstand the test of time.

MDI PU screen panels provide significant cost efficiency for construction projects, making them a smart investment for contractors and builders alike. The use of these panels helps to minimize material waste during the construction process, as they are designed to be more durable and long-lasting compared to traditional materials. This durability means that the panels can withstand the rigors of construction, reducing the need for frequent replacements and repairs, ultimately leading to lower overall project costs.

Additionally, MDI PU screen panels are lightweight and easy to handle, which streamlines the installation process. This reduces labor costs as fewer workers are needed to install the panels efficiently. Their adaptability also allows for quicker modifications and adjustments on-site, saving valuable time and further contributing to cost savings. By incorporating MDI PU screen panels into construction projects, builders can achieve a balance of performance and affordability, ensuring that they stay within budget while delivering high-quality results.

MDI PU screen panels are becoming increasingly popular in construction due to their significant environmental benefits and sustainability features. With growing emphasis on eco-friendly materials, MDI (Methylene Diphenyl Diisocyanate) polyurethane exhibits excellent environmental compatibility. These panels are produced with a low environmental impact, resulting in reduced emissions during manufacturing and contributing to a smaller ecological footprint.

Moreover, MDI PU screen panels are designed for durability and long-lasting performance, which translates to lower resource consumption over time. Their lightweight nature minimizes transportation energy, and their resistance to harsh weather conditions ensures they do not need frequent replacements. Additionally, these panels are fully recyclable, further enhancing their sustainability profile by reducing waste in landfills. This cyclical approach to material use aligns with contemporary green construction practices, promoting a healthier environment while meeting the demands of modern construction projects.