No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the competitive landscape of modern industries, the efficiency and reliability of production processes are paramount. One innovative solution gaining traction among businesses is the Mdi Pu Tension Screen. According to a recent report by MarketsandMarkets, the global market for screening equipment is projected to reach $3.2 billion by 2025, driven by increasing demand for raw materials and minerals, coupled with the need for enhanced process efficiency. The Mdi Pu Tension Screen not only improves operational efficiency but also offers exceptional durability and resistance to wear, ultimately leading to cost savings and reduced downtime. This blog will explore how incorporating Mdi Pu Tension Screens into your operations can provide significant benefits, streamlining processes and enhancing overall productivity in today’s fast-paced market.

In today's competitive landscape, modern manufacturing industries are increasingly relying on advanced materials and technologies to enhance operational efficiency and product quality. One such innovation is the MDI PU tension screen, which plays an essential role in various production processes. These screens, made from Methylene Diphenyl Diisocyanate (MDI) polyurethane, offer remarkable durability and flexibility, making them an ideal choice for applications requiring high tensile strength and resistance to wear. Their lightweight nature not only reduces the overall machinery load but also facilitates easier handling and installation, contributing to improved productivity.

Moreover, MDI PU tension screens are designed to optimize filtration and separation processes, ensuring that only products meeting stringent quality standards make it to the market. Their effective performance leads to minimal downtime and maintenance costs, significantly impacting the bottom line for manufacturing businesses. By incorporating these screens into their operations, companies can benefit from consistent quality outputs, enhanced efficiency, and a competitive edge in their respective industries. The alignment of MDI PU tension screens with the demands of modern manufacturing underscores their vital role in driving innovation and sustainability.

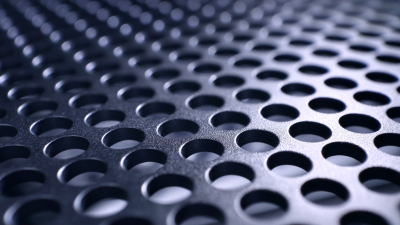

MDI PU tension screens have emerged as a game-changer for businesses aiming to enhance product quality across various industries. One of the key advantages of these screens is their superior durability compared to traditional mesh options. Made from high-performance MDI polyurethane, they offer resistance to wear and tear, allowing companies to reduce downtime and maintenance costs. The robust nature of MDI PU tension screens also ensures consistent performance under varying operating conditions, providing reliable results for processing materials.

Another significant benefit is the enhanced filtering capability of MDI PU tension screens. Their finely engineered structure ensures optimal separation of target materials, leading to higher purity levels in the final product. This improvement not only elevates product quality but also aligns with strict regulatory standards, making it an excellent choice for industries focused on compliance. Additionally, the lightweight design of these screens facilitates easier installation and handling, ultimately contributing to increased operational efficiency. By investing in MDI PU tension screens, businesses can significantly improve their output quality while streamlining their production processes.

MDI PU tension screens have increasingly become a preferred option for businesses looking to enhance their screening processes. When we compare MDI PU tension screens with traditional screening methods, the benefits become evident, particularly in the context of cost-effectiveness and operational efficiency.

Traditional vibrating screens, while effective, often face issues such as critical particle blockage, which can hinder productivity and increase maintenance costs. Recent studies indicate that innovative designs, like flip-flow vibrating screens (FFVS), can mitigate these issues by utilizing periodic high-frequency flexure deformation, allowing for improved particle separation in various applications, including coal cleaning production.

MDI PU tension screens have increasingly become a preferred option for businesses looking to enhance their screening processes. When we compare MDI PU tension screens with traditional screening methods, the benefits become evident, particularly in the context of cost-effectiveness and operational efficiency.

Traditional vibrating screens, while effective, often face issues such as critical particle blockage, which can hinder productivity and increase maintenance costs. Recent studies indicate that innovative designs, like flip-flow vibrating screens (FFVS), can mitigate these issues by utilizing periodic high-frequency flexure deformation, allowing for improved particle separation in various applications, including coal cleaning production.

Moreover, the advancements in screening technology, such as the equibiaxial tension test methods applied to hyperelastic membranes, have revealed that modern tension screens, like MDI PU screens, exhibit superior mechanical properties. This translates into increased durability and reduced replacement frequency compared to conventional methods. Consequently, businesses that adopt MDI PU tension screens may experience lower long-term operational costs, as they not only minimize downtime but also enhance overall efficiency. By leveraging these modern technologies, companies can achieve a significant return on investment while ensuring high-quality separation processes.

MDI PU tension screens are revolutionizing the way businesses approach durability and performance in demanding environments. The MDI (Methylene Diphenyl Diisocyanate) polyurethane material offers exceptional resilience compared to traditional screen materials. According to a recent report by MarketsandMarkets, the global polyurethane market is projected to reach USD 73.6 billion by 2025, highlighting the increasing reliance on advanced materials like MDI PU in various industries. These advancements contribute to longer screen lifespans, with many users reporting up to 30% increased durability in MDI PU screens compared to typical polyester-based options.

In addition to their durability, MDI PU tension screens exhibit superior performance attributes, such as resistance to wear and tear while maintaining consistent tension. Industry tests indicate that MDI PU screens can withstand higher temperatures and harsher chemicals, which is crucial for operations in sectors like mining, food processing, and recycling. A study conducted by the Global Polyurethane Alliance found that equipment downtime due to screen failures can be reduced by 25% with the implementation of MDI PU tension screens, leading to improved productivity and operational efficiency. With these impressive metrics, it's clear that investing in MDI PU technology not only enhances the longevity of equipment but also significantly impacts the bottom line for businesses.

The market for MDI PU tension screens is witnessing notable growth, driven by the increasing demand for efficient and durable solutions in various industries. According to a report by Grand View Research, the global polyurethane market is projected to reach $82.3 billion by 2025, growing at a CAGR of 7.9%. This trend reflects a broader movement towards advanced material solutions that enhance operational efficiency, particularly in sectors such as construction, mining, and recycling. MDI PU tension screens, known for their superior tensile strength and flexibility, are becoming essential for companies aiming to optimize their production processes.

Furthermore, a report from MarketsandMarkets suggests that the adoption of tension screening technology is increasing due to stricter environmental regulations and the need for more sustainable production methods. Industries are leaning towards MDI PU screens not only for their performance but also for their longevity and reduced maintenance costs. With the ability to withstand harsh conditions while ensuring high screening efficiency, MDI PU tension screens are set to redefine operational standards in global markets, aligning with the growing emphasis on eco-friendly practices and cost-effective solutions.

| Benefits | Industry Adoption Rate (%) | Market Growth Rate (%) | Key Applications |

|---|---|---|---|

| Enhanced Durability | 35 | 8.5 | Manufacturing & Construction |

| Cost Efficiency | 50 | 7.2 | Mining & Minerals |

| Improved Filtration | 40 | 9.1 | Chemical Processing |

| Versatile Applications | 45 | 8.0 | Agriculture & Food Processing |

| Sustainability Features | 30 | 7.8 | Environmental Management |