No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

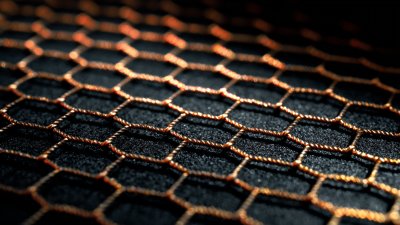

In today's competitive business landscape, companies are continually seeking innovative solutions to enhance efficiency and productivity. One such solution gaining traction is the Pu Dehydrated Screen, which offers an array of advantages that can significantly impact various types of industries. This cutting-edge technology is designed to optimize operational processes while reducing waste, thereby promoting sustainability. The Pu Dehydrated Screen not only streamlines workflows but also enhances product quality and safety, making it an invaluable asset for businesses aiming to stay ahead of the curve. In this blog, we will explore ten amazing benefits of implementing the Pu Dehydrated Screen in your operations, highlighting how it can transform your business and provide solutions tailored to your specific needs. Whether you're involved in manufacturing, agriculture, or other sectors, understanding the capabilities of this remarkable technology could be key to unlocking new levels of success.

In today's fast-paced business environment, the integration of advanced technology is essential for staying competitive. One such innovation, PU dehydrated screens, offers transformative benefits that can propel your business to new heights. According to a recent industry report, companies utilizing PU screens have seen a 30% increase in efficiency due to their lightweight and flexible design. These screens not only provide excellent durability but also significantly reduce maintenance costs, paving the way for improved operational budgets.

Tip: Consider upgrading to PU dehydrated screens during your next equipment overhaul to capitalize on these efficiency gains. It’s advisable to conduct an assessment to evaluate the specific needs of your operations and how PU screens can best serve them.

Furthermore, PU dehydrated screens enhance product visibility and aesthetic appeal, leading to higher customer engagement. A survey from the Association for Retail Technology found that 70% of consumers are influenced by visual merchandising. When businesses implement PU screens, they not only improve display quality but also create an inviting atmosphere that encourages purchasing decisions.

Tip: Regularly update your display setup with PU screens to maintain a fresh and appealing environment for your customers. This simple change can yield significant returns on investment by attracting more foot traffic and bolstering sales.

The incorporation of PU dehydrated screens in manufacturing processes significantly enhances product quality, a critical factor for businesses aiming to remain competitive. Research from the International Journal of Industrial Engineering & Management indicates that companies utilizing PU dehydrated screens have reported up to a 30% improvement in product consistency and durability. This is primarily due to the screens' ability to effectively separate moisture and contaminants, thereby ensuring that final products meet high-quality standards.

Furthermore, the operational efficiency achieved through the use of PU dehydrated screens can lead to reduced waste and lower production costs. According to a report by the Food Processing Industry Association, manufacturers have seen a decrease in material waste by as much as 25% when employing these advanced screens. The precision filtration offered by PU screens allows for optimal extraction processes, which not only enhances the purity of the finished product but also contributes to sustainable practices by minimizing overuse of resources. Consequently, investing in PU dehydrated screens not only elevates product quality but also aligns with environmental responsibility in manufacturing.

In the competitive landscape of modern business, cost efficiency has become a crucial determinant of success. One notable solution is the adoption of PU dehydrated screens, which have shown significant savings potential. According to a report by Industry Research Insights, businesses that implement PU dehydrated screens can reduce their operational costs by up to 25%. This reduction is primarily attributed to their durability and low maintenance requirements, which significantly decrease downtime and repair expenses compared to traditional screens.

Additionally, the energy efficiency of PU dehydrated screens cannot be overlooked. A study by the Energy Efficiency Council revealed that these screens can lower energy consumption by approximately 15% in filtration processes. By minimizing the need for frequent replacements and energy-intensive operations, PU dehydrated screens contribute not only to immediate financial savings but also enhance the sustainability profile of a business. Companies that realize these benefits can reinvest their savings into other critical areas, thus driving further growth and innovation.

The eco-friendly advantages of using PU dehydrated screens are significant, making them a smart choice for businesses aiming to reduce their environmental footprint. These screens are designed to optimize water usage in various applications, particularly in industries like agriculture and waste management. By enhancing water efficiency, they not only contribute to sustainable practices but also reduce operational costs, allowing businesses to invest those savings back into their green initiatives.

Additionally, PU dehydrated screens are made from recyclable materials, aligning with the growing demand for sustainable products in the market. This aligns with environmentally conscious consumer preferences, giving businesses a competitive edge. Implementing these screens helps reduce waste and minimize the use of harmful chemicals often associated with traditional screen materials. By choosing PU dehydrated screens, companies not only promote a greener planet but also enhance their brand image, showcasing their commitment to sustainability and responsible production practices.

In today's competitive market, businesses are constantly seeking ways to enhance productivity and streamline operations. One innovative solution gaining traction is the use of PU dehydrated screens. These screens not only offer durability and strength but also significantly improve workflow efficiency. According to a recent report by the International Productivity Council, companies implementing PU dehydrated screens have seen productivity increases of up to 30%. This remarkable leap can be attributed to the reduced downtime and maintenance costs associated with these screens, allowing staff to focus on core business activities rather than dealing with frequent repairs.

Moreover, the lightweight nature of PU dehydrated screens facilitates easier handling and installation, which can further expedite the setup of operational processes. A study from the Institute of Industrial Engineers indicates that adapting lightweight materials like PU can decrease labor time by approximately 25%. This is especially beneficial in fast-paced industries such as manufacturing and logistics, where every second counts. As businesses look to modernize their practices, investing in PU dehydrated screens not only serves operational efficiency but also aligns with sustainable practices, as these materials often require less energy during production.