No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

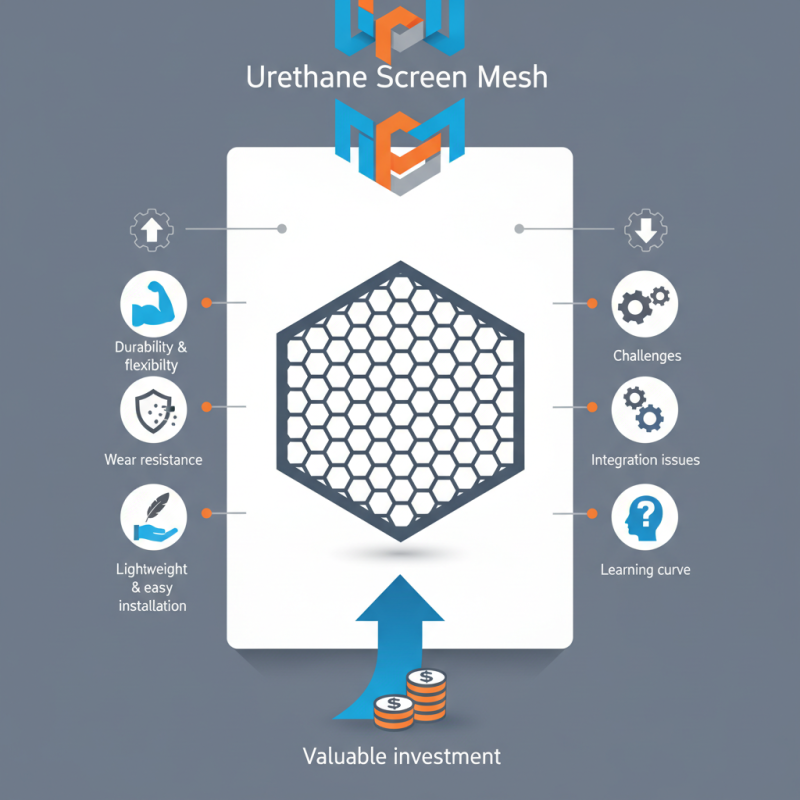

In the realm of industrial applications, materials play a crucial role in ensuring efficiency and effectiveness. One such material that stands out is Urethane Screen Mesh. This innovative product offers numerous benefits that can greatly enhance operational processes. Its durability and flexibility make it an ideal choice for various screening tasks in different industries.

Urethane Screen Mesh provides excellent wear resistance. It outperforms traditional materials, handling abrasive materials with ease. Many users appreciate its lightweight nature, which simplifies installation. Additionally, the mesh’s ability to maintain its structure under heavy loads is particularly appealing in high-stress environments.

However, adopting Urethane Screen Mesh is not without challenges. Some users have reported integration issues with existing systems. There is a learning curve associated with this material, requiring careful consideration. Despite these hurdles, the advantages of using Urethane Screen Mesh cannot be overlooked. It represents a valuable investment for industries seeking to improve their screening operations.

Urethane screen mesh offers several advantages over traditional materials used in industrial applications. Its flexibility and strength are notable. This mesh resists tearing and abrasion, which is crucial in tough industrial environments. Many industries require durable and long-lasting materials. Urethane meets these needs effectively.

One of the most appealing features is its lightweight nature. This property makes handling much easier. Workers can install and remove it without excessive strain. Furthermore, urethane’s resistance to chemical damage ensures longer service life. Many traditional materials degrade quickly when exposed to harsh substances. This leads to increased maintenance costs, which urethane helps to avoid.

However, it is important to reflect on the potential downsides. Although urethane is strong, it can warp under extreme heat. This is something to consider during high-temperature operations. Additionally, while it is generally more durable, improper installation can lead to failures. Understanding these limitations is essential for optimizing its benefits in various applications.

Urethane screen mesh stands out in industrial applications due to its remarkable durability. This material can withstand harsh conditions that often challenge traditional options. It resists severe abrasion and degradation. In environments with heavy impact, urethane maintains its integrity longer than most competitors.

Its longevity is particularly notable in mining or recycling sectors. Here, screens encounter constant wear from materials like rocks or metals. Urethane's resilience means fewer replacements, which can reduce downtime. This leads to substantial cost savings over time. However, users must reflect on installation specifics to maximize performance.

Despite its strengths, some limitations exist. Urethane mesh may not be suitable for extreme temperatures. It also requires careful handling during installation. Ensuring correct tensioning is crucial. Otherwise, potential failures could arise, affecting overall operations. A thorough understanding of both its benefits and caveats ensures it performs optimally in challenging environments.

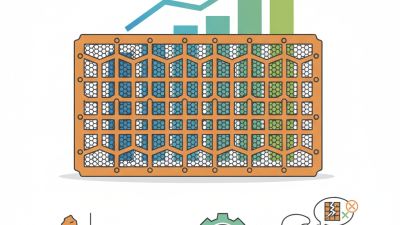

| Benefit | Description | Impact |

|---|---|---|

| Durability | Resistance to wear and tear in challenging conditions. | Reduces replacement costs and downtime. |

| Longevity | Extended lifespan compared to traditional materials. | Increased efficiency and lower long-term expenses. |

| Versatility | Effective in various industries like mining, agriculture, and recycling. | Wide range of applications enhances operational flexibility. |

| Resistance to Chemicals | Withstands exposure to corrosive substances. | Improves longevity in harsh environments. |

| Lightweight Design | Easy to handle and install due to reduced weight. | Saves on labor costs and improves deployment speed. |

Urethane screen mesh offers significant cost efficiency in industrial settings. Its durability reduces the need for frequent replacements. Over time, this translates to lower maintenance expenses. Regular maintenance on traditional materials can be costly. Urethane materials require less attention, saving both time and money.

In harsh environments, urethane resists wear and tear. It withstands heavy loads and abrasive materials without immediate damage. However, it is crucial to monitor your equipment regularly. Even durable materials can face unexpected failures. This attention to detail ensures optimal performance and longevity.

Companies often underestimate the value of using urethane. Initial costs may appear high, but the long-term savings are substantial. With reduced wear and fewer replacements, the overall investment pays off. Still, organizations need to train staff properly. Misuse can negate the cost benefits of this innovative screen mesh.

Urethane screen mesh showcases exceptional versatility across various industrial sectors. Its adaptability makes it suitable for industries like mining, food processing, and waste management. In mining, this mesh withstands abrasive conditions while maintaining structural integrity. It resists wear and tear better than traditional materials. This durability extends its lifespan, but it may still require periodic replacements that can disrupt operations.

In food processing, urethane screen mesh is easy to clean and maintain. The non-stick properties prevent food residues from accumulating, thus enhancing hygiene standards. However, it may still face challenges with certain sticky substances. This variability in performance can lead to unexpected maintenance needs.

Moreover, urethane mesh finds value in waste management. It helps separate various materials efficiently. The ability to filter diverse waste types is impressive, but it may not always provide perfect separation. While many sectors benefit from its use, the mesh’s limitations should not be overlooked. Clearly, understanding these nuances is crucial for maximizing its potential in industrial applications.

Urethane screen mesh has transformed how industries approach screening. This material brings numerous advantages that enhance screening efficiency significantly. With its unique properties, urethane screen mesh allows for higher throughput. It can process more materials in less time, which is crucial in fast-paced environments.

One of the standout features of urethane screen mesh is its durability. Unlike traditional mesh options, it withstands heavy loads and abrasive materials without significant wear. This resilience translates to less downtime for maintenance and replacements. However, industries must reevaluate their screening processes. It’s vital to consider whether the investment in urethane mesh justifies the switch from cheaper alternatives.

Quality is another aspect where urethane excels. It minimizes material loss during screening, allowing for better recovery rates. This efficiency ultimately leads to improved product quality. But not all facilities may notice an immediate boost. Proper training and adjustment to new materials are necessary. Continuous monitoring of screening efficiency can help identify any persistent challenges.