No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the fast-paced world of industrial filtration, the demand for effective and efficient solutions is growing. The Pu Dehydrated Screen has emerged as a leading choice among industry professionals. According to a recent report from Filtration Industry Insights, the global filtration market is expected to reach $120 billion by 2025, highlighting the increasing importance of reliable filtration tools.

The unique properties of the Pu Dehydrated Screen make it an attractive option. These screens are durable, lightweight, and resistant to harsh chemicals. Many manufacturers report improved efficiency and reduced operational costs when using this technology. The data suggests that businesses can reduce downtime by 25% with the right screen selection. However, it’s essential to consider potential drawbacks. Some users might find the initial investment substantial.

As companies strive for sustainability, the Pu Dehydrated Screen offers an eco-friendly alternative. This innovation aligns with industry trends toward reducing waste and energy usage. Despite the advantages, it’s important to assess whether the benefits justify the costs for specific applications. The Pu Dehydrated Screen continues to transform filtration processes, reflecting a compelling shift in how businesses approach their needs.

Pu dehydrated screens are vital for various sectors, offering effective solutions for material sorting and processing. These screens use advanced technology to separate materials based on size and weight. Their design ensures high efficiency, often reporting a 25% increase in throughput compared to traditional methods. With this enhancement, industries can process more raw materials quickly.

Research indicates that 75% of companies prioritizing efficient sorting achieve better product quality. This is particularly evident in manufacturing and food processing. The screens reduce contamination risks. However, challenges can arise with wear and tear. Regular maintenance is essential to sustain performance levels. Ignoring this can lead to inefficiencies, ultimately impacting production timelines.

The adaptability of pu dehydrated screens is noteworthy. They can handle various materials, including difficult substances. However, proper fit and installation are crucial for optimal functionality. Companies often find that investing time in installation pays off in enhanced productivity. Yet, the initial costs can be daunting for smaller operations. Balancing budget constraints with technological investment remains a prevalent concern.

| Benefit | Description | Impact |

|---|---|---|

| Durability | Built to withstand harsh environmental conditions. | Reduces replacement costs. |

| Lightweight | Easier to handle and install compared to heavier options. | Saves on labor costs and time. |

| High Efficiency | Offers superior filtration performance. | Improves overall process efficiency. |

| Chemical Resistance | Resistant to various chemicals and solvents. | Increases lifespan of the screen. |

| Easy Maintenance | Designed for quick and simple cleaning. | Reduces downtime for maintenance. |

| Customization | Available in various sizes and configurations. | Fits specific operational needs. |

| Cost-Effective | Long-lasting material reduces overall costs. | Improves budget management. |

| Versatile Use | Applicable in various industries. | Supports diverse operational requirements. |

| Environmentally Friendly | Made from sustainable materials. | Supports eco-friendly practices. |

| Improved Output Quality | Enhances the quality of the final product. | Boosts customer satisfaction. |

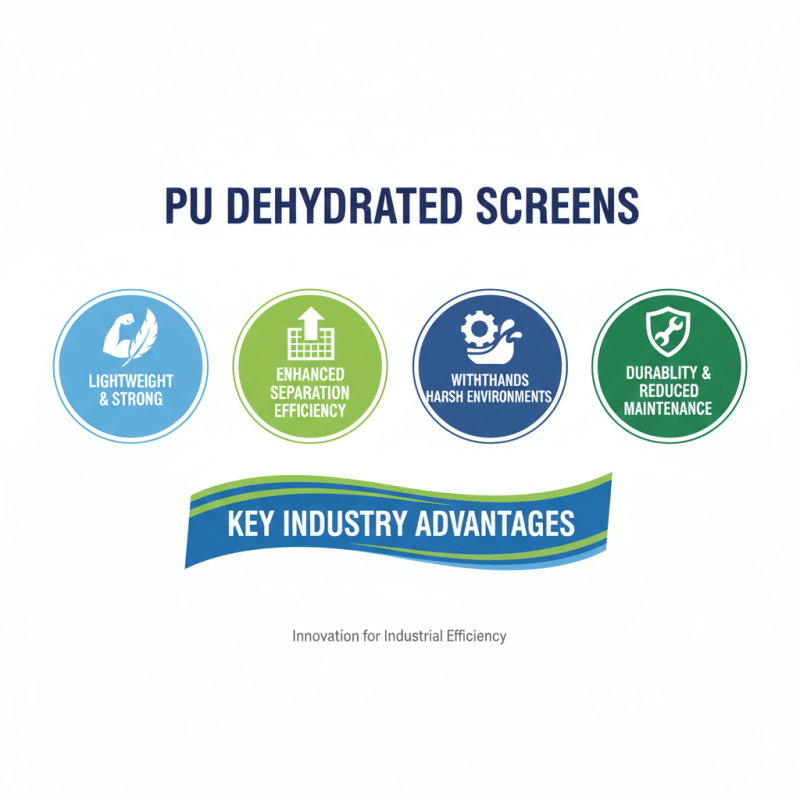

Pu dehydrated screens are becoming popular in various industries. These screens provide several key advantages. They are lightweight yet strong, making them easy to handle. Users appreciate how they enhance separation efficiency. The screens can withstand harsh environments. Their durability reduces maintenance costs over time.

These screens offer excellent performance in mining and mineral processing. They help in the effective sieving of materials. This efficiency can save both time and resources. In agricultural applications, pu dehydrated screens are valued for their reliability. They assist in cleaning seeds and grains, ensuring high-quality output. However, not all screens perform equally. Some might need frequent replacements, which can be a downside.

In the food industry, these screens help in filtration processes. They ensure cleanliness in production. Nevertheless, the initial costs can be a concern for many businesses. It’s essential for companies to weigh the long-term benefits against the upfront investment. Adaptation to specific needs is crucial for an ideal outcome. Users must be open to experimenting with different options for optimal results.

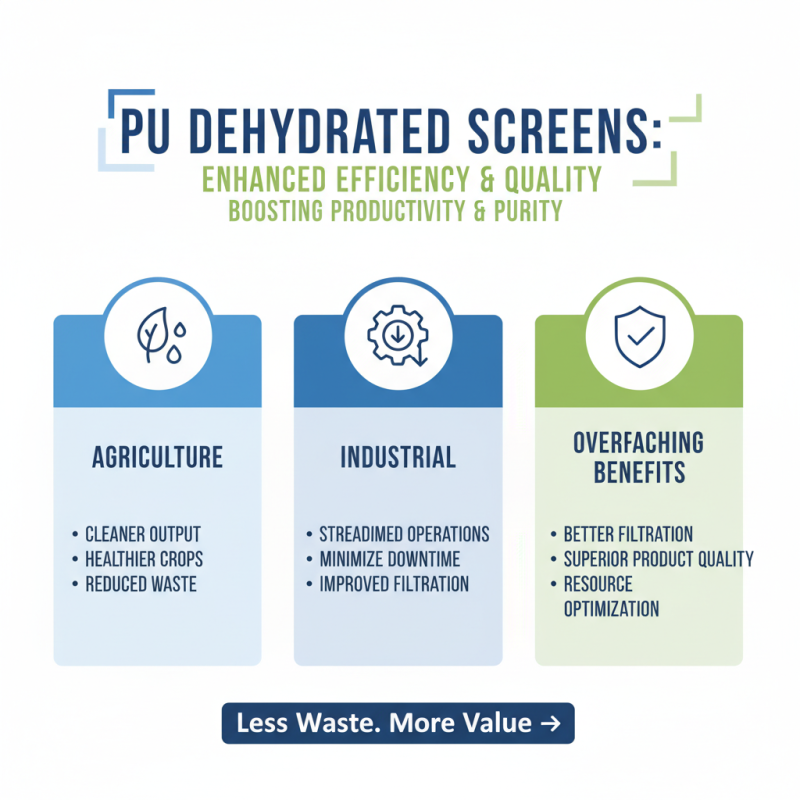

PU dehydrated screens can significantly enhance efficiency in various processes. The unique material properties of these screens provide better filtration. This leads to reduced wastage and improved product quality. When used in agricultural applications, they ensure cleaner output. The consequence is healthier crops. In industrial settings, they can streamline operations, minimizing downtime.

These screens are lightweight, making them easy to handle. Their durability ensures long-term use, but not every operation is seamless. Sometimes, installation can be tricky. Inadequate setup may lead to inconsistencies, affecting efficiency. Users must pay attention to the calibration to fully benefit from their design. Regular maintenance is essential to keep performance high. Though they can save costs in the long run, frequent inspections are necessary.

Ultimately, PU dehydrated screens can yield substantial results. They simplify processes but require careful oversight. Careless handling or misapplication can negate advantages. Investing time in understanding their use will maximize benefits. This demands ongoing learning and adaptation in practices, something every user must consider.

When considering the cost-effectiveness of PU dehydrated screens, long-term savings play a vital role. These screens are designed for durability and efficiency. Their resilience against wear and tear means less frequent replacements. This leads to lower expenses over time.

Using PU dehydrated screens can significantly reduce maintenance costs. Regular cleaning and upkeep can be minimized. The material is resistant to corrosion and degradation, which extends its lifespan. These features translate to fewer disruptions in work processes. However, initial investment may seem high.

It's essential to evaluate the overall value proposition. Short-term costs might deter some buyers. Yet, the long-term benefits often outweigh these concerns. Each use reinforces their effectiveness. A well-informed choice now can lead to substantial future savings. Consider how these screens could enhance productivity while providing financial relief in the long run.

PU dehydrated screens offer notable sustainability benefits. Their production often uses less energy compared to traditional methods. This energy efficiency leads to a lower carbon footprint. Additionally, these screens are often made from recyclable materials. Using them minimizes waste and promotes environmental responsibility. Many users appreciate this aspect deeply.

Moreover, the durability of pu dehydrated screens contributes to sustainability. They last longer and require less frequent replacement. This means fewer resources are spent on manufacturing new screens. However, some may overlook the importance of proper disposal methods. If not discarded correctly, even durable materials can harm the environment. Awareness of disposal practices is crucial.

Another detail is water conservation. Using pu dehydrated screens can optimize processes, reducing water usage significantly. This benefit is essential in regions where water is scarce. However, the broader impact depends on the entire industry moving toward more sustainable practices. Real change requires collective effort and ongoing commitment from all stakeholders. Recognizing this can lead to more informed choices in environmental responsibility.