No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

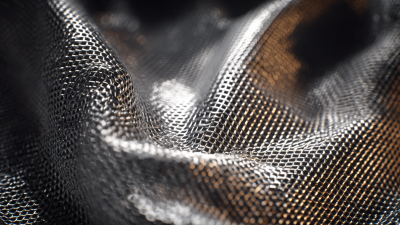

The filtration industry has seen significant advancements in recent years, particularly in the use of Fine Mesh screens for various applications. According to a recent report by the Filtration Society, the demand for high-quality filtration solutions is projected to grow by over 5% annually through 2025, driven by sectors such as food and beverage, pharmaceuticals, and environmental engineering. Fine Mesh screens, known for their precision and versatility, are pivotal in ensuring optimal filtration and separation processes.

Expert in the filtration field, Dr. Emily Vargas, emphasizes the importance of choosing the right materials for effective filtration. She states, "The right Fine Mesh not only enhances the quality of the final product but also increases operational efficiency by reducing waste." This sentiment reflects the growing recognition of Fine Mesh technology's role in maintaining high standards in production and processing environments.

As industries continue to prioritize sustainability and quality, Fine Mesh screens have emerged as indispensable tools. Their ability to fine-tune filtration processes makes them suitable for a range of projects, from industrial applications to DIY home improvements. In this article, we will explore the top 10 Fine Mesh screens available on the market today, highlighting their features and benefits for ultimate filtration in your projects.

Fine mesh screens are essential tools in various industrial and home applications due to their superior filtration capabilities. These screens, typically composed of woven stainless steel or nylon, have openings ranging from 20 to 400 microns, which allows them to capture particles while permitting liquids or gases to pass through. According to a report by the Filtration Society, industries such as food processing, pharmaceuticals, and water treatment have recognized the value of fine mesh screens in enhancing product purity and efficiency, reducing contamination risk by up to 90%.

In construction and manufacturing, fine mesh screens play a pivotal role in controlling the quality of raw materials. For instance, when used in concrete production, these screens can filter out unwanted aggregates, ensuring a consistent mixture that meets regulatory standards. Studies have shown that employing fine mesh screens in this process can improve compressive strength by 15% while minimizing the likelihood of cracking and other structural deficiencies. As filtration technology continues to evolve, the adoption of specialized fine mesh solutions is increasingly seen as a means to innovate and streamline operations across a range of sectors.

When selecting a fine mesh screen for your filtration projects, several key features should be taken into account to ensure optimal performance. First, consider the mesh material itself; options like stainless steel or nylon offer varying levels of durability and resistance to corrosion, making them suitable for different environments. Additionally, the mesh count is a critical factor, as it dictates the size of particles that can be filtered out. Choosing a higher mesh count can be beneficial for applications requiring fine filtration, while a lower count might be preferable for coarser materials.

Another important aspect to evaluate is the screen’s frame construction. A robust frame not only enhances the longevity of the screen but also ensures that it can maintain its shape under pressure during use. Proper sizing is also crucial, as a screen that fits well within your setup will reduce the risk of bypassing unwanted particles. Finally, consider ease of cleaning and maintenance; screens that can be easily disassembled or cleaned will contribute to a more efficient and productive filtration process over time. By focusing on these key features, you can select a fine mesh screen that aligns perfectly with your project requirements.

When it comes to selecting fine mesh screens for your projects, understanding the various options available can greatly enhance your filtration processes. Fine mesh screens come in various materials, sizes, and mesh openings, allowing you to tailor your choices to specific needs, whether in cooking, gardening, or industrial applications. Consider the mesh material; stainless steel is durable and resistant to rust, while nylon offers flexibility and lightweight convenience.

Tips: Always match the mesh size to your intended use. For instance, smaller mesh openings are ideal for sifting fine particles, whereas larger ones are more suitable for coarse filtration. Ensure that the frame is sturdy enough to maintain the screen's integrity during use. Additionally, look for screens that are easy to clean for efficient maintenance practices.

Another consideration is the screen's compatibility with your project environment. For outdoor projects, UV-resistant materials may extend the screen’s lifespan. For food-related applications, ensure the screen materials are food-safe and easy to sanitize. By being mindful of these factors, you can select the perfect fine mesh screen to optimize your filtration needs.

Fine mesh screens are essential tools in various industries, providing unmatched filtration capabilities for a wide range of applications. A comparative analysis of filtration efficiency reveals that screens with finer mesh sizes—typically ranging from 20 to 400 microns—can effectively capture particles as small as 1 micron, yielding higher purity in collected materials. Industry reports indicate that using finer mesh screens can reduce contamination levels by up to 97%, significantly improving the quality of products in sectors like food processing, pharmaceuticals, and water treatment.

Furthermore, the material composition and weave pattern of fine mesh screens play a crucial role in their overall effectiveness. Research suggests that stainless steel screens generally offer superior durability and resistance to corrosion, making them ideal for demanding environments. A study published in the Journal of Filtration Science noted that screens with a plain weave design exhibited a higher retention rate compared to twill weave patterns due to their consistent pore structure. This consistency is essential for maintaining flow rates and ensuring optimal filtration during operations. Such insights underline the importance of selecting the appropriate mesh screen based on the specific requirements of filtration efficiency and application.

To prolong the life of fine mesh screens, proper maintenance is essential. Regular cleaning is the first step; debris and sediment can accumulate over time, leading to blockages that hinder functionality. Use a soft brush or a gentle wash to remove particles without damaging the mesh. If possible, rinse with water to dislodge stuck residues. Avoid using harsh chemicals that can degrade the material and affect its integrity.

Moreover, storing fine mesh screens correctly is crucial for their durability. When not in use, ensure they are kept in a dry, cool place to prevent rust and corrosion, particularly if they are made from metal. Avoid stacking heavy items on top of them, which can cause bending or deformation. Regular inspections for wear and tear can help identify early signs of damage, allowing for repairs or replacements before significant issues arise. By following these maintenance tips, users can maximize the lifespan and efficiency of their fine mesh screens, ensuring optimal performance in various applications.