No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the evolving landscape of industrial applications, the selection of high-quality components is paramount for ensuring operational efficiency and reliability. One crucial element in various industries is the Pu Dehydrated Screen, known for its remarkable performance in separating materials efficiently.

According to a recent industry report by MarketsandMarkets, the global market for dehydration screens is projected to reach USD 25 billion by 2026, driven by increasing demands for effective solid-liquid separation processes across sectors such as mining, food processing, and wastewater management. As businesses strive to enhance productivity and minimize downtime, understanding the critical factors in choosing the

right Pu Dehydrated Screen becomes essential. This ultimate checklist aims to guide stakeholders through the selection process, ensuring they invest in products that meet their specific operational needs while adhering to industry standards.

According to a recent industry report by MarketsandMarkets, the global market for dehydration screens is projected to reach USD 25 billion by 2026, driven by increasing demands for effective solid-liquid separation processes across sectors such as mining, food processing, and wastewater management. As businesses strive to enhance productivity and minimize downtime, understanding the critical factors in choosing the

right Pu Dehydrated Screen becomes essential. This ultimate checklist aims to guide stakeholders through the selection process, ensuring they invest in products that meet their specific operational needs while adhering to industry standards.

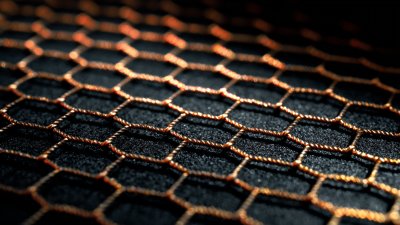

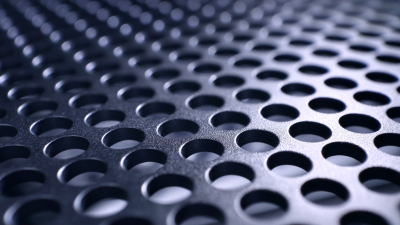

When selecting a high-quality PU dehydrated screen, it’s essential to focus on several key features that can determine the product's effectiveness and longevity. One of the first aspects to examine is the screen's material and construction. Look for screens made from durable, high-grade polyurethane that can withstand environmental factors such as UV exposure and physical wear. This durability ensures that the screen remains functional over time, maintaining its performance in various applications.

Another crucial feature to consider is the screen's mesh size and design. A well-designed mesh not only affects the filtration efficiency but also influences the overall flow rate. Optimal mesh size achieves a balance between thorough dehydration and rapid processing speed. Additionally, consider any special treatments or coatings that may enhance the screen’s resistance to contamination or clogging. By paying attention to these essential elements, you can ensure that your PU dehydrated screen meets your specific needs and provides long-lasting, reliable performance.

When selecting a high-quality PU dehydrated screen, understanding the various grades available can significantly impact your choice. Different grades of polyurethane screens are designed to meet specific application requirements, and they vary in performance characteristics such as durability, flexibility, and resistance to wear and chemicals. For instance, high-grade screens often incorporate advanced materials that enhance their mechanical and thermal properties, making them suitable for more demanding environments. This ongoing innovation in screen manufacturing reflects the industry's shift towards safer and more efficient materials, such as those that avoid hazardous substances in splicing procedures.

When selecting a high-quality PU dehydrated screen, understanding the various grades available can significantly impact your choice. Different grades of polyurethane screens are designed to meet specific application requirements, and they vary in performance characteristics such as durability, flexibility, and resistance to wear and chemicals. For instance, high-grade screens often incorporate advanced materials that enhance their mechanical and thermal properties, making them suitable for more demanding environments. This ongoing innovation in screen manufacturing reflects the industry's shift towards safer and more efficient materials, such as those that avoid hazardous substances in splicing procedures.

In addition to these advancements, recent developments highlight the importance of customized solutions in the polyurethane screen market. Companies are focusing on innovating their product offerings to cater to unique client needs, which can range from enhanced disintegration resistance to improved operational efficiency under variable environmental conditions. Understanding the grading system and the specific benefits of each type can allow users to make more informed decisions, ensuring optimal performance in their operational contexts. Thus, thorough research into the grades of PU dehydrated screens can lead to significant long-term benefits in terms of productivity and equipment longevity.

When it comes to selecting a high-quality PU dehydrated screen, understanding the balance between cost and quality is essential. Investing in a premium PU screen often means spending more initially, but the benefits in durability and performance can lead to significant cost savings in the long run. A lower-priced screen may seem appealing, but it often comes with compromises in material and construction quality, leading to frequent replacements and increased downtime.

To get the best value, focus on suppliers who provide transparent information about their products, including the manufacturing process and materials used. Look for screens that not only meet your current needs but are also designed to withstand varying conditions over time. Reading reviews and seeking recommendations can also provide insight into which products offer the right mix of affordability and quality, ensuring your investment is wisely spent and delivers the performance you expect.

| Feature | High Quality PU Screen | Mid Range PU Screen | Low Quality PU Screen |

|---|---|---|---|

| Cost (USD) | $150 | $100 | $50 |

| Material Integrity | Highly Durable | Moderately Durable | Less Durable |

| Screen Thickness | 2.5 mm | 2.0 mm | 1.5 mm |

| UV Resistance | Excellent | Good | Poor |

| Warranty Period | 3 Years | 2 Years | 1 Year |

| User Reviews (out of 5) | 4.8 | 4.0 | 3.5 |

When selecting a high-quality PU dehydrated screen, it's essential to consider well-established brands and manufacturers that have a proven track record in the industry. Top brands such as **Brand A**, **Brand B**, and **Brand C** offer products designed for durability and superior performance. These companies invest in research and development to innovate their designs and materials, ensuring their screens can withstand rigorous use while providing efficient dehydration.

**Tip:** Always look for customer reviews and testimonials when assessing different brands. Feedback from other users can provide valuable insights into the durability and efficiency of the screens you are considering. Additionally, check for certifications or quality standards that the manufacturers comply with, as these can indicate a commitment to high-quality production processes.

Another aspect to consider is the availability of customer support and warranty options from the manufacturers. Reputable brands often provide comprehensive support for their products and a reliable warranty period. This guarantees that you receive assistance in case of any defects or issues that arise after purchase.

**Tip:** Don't hesitate to reach out to manufacturers directly with questions or for information on their screens’ specifications. A responsive customer service team is often a good indicator of the overall quality and reliability of a brand.

To prolong the lifespan of your PU dehydrated screen, regular maintenance is key. Start by ensuring that the screen is cleaned frequently using soft brushes or cloths to remove any residue or debris that may compromise its performance. Avoid using abrasive materials or harsh chemicals, as these can damage the polyurethane surface. Instead, opt for mild detergents diluted with water, which will effectively cleanse the screen without causing wear.

Another essential maintenance tip is to monitor the operating conditions in which the screen is used. Excessive heat or moisture can lead to premature degradation of the PU material. It’s advisable to store the screen in a climate-controlled environment when not in use. Additionally, inspect the screen regularly for signs of wear and tear, such as cracks or loss of elasticity. Addressing these issues early can prevent more significant problems down the line, ensuring that your PU dehydrated screen continues to perform at its best for an extended period.