No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

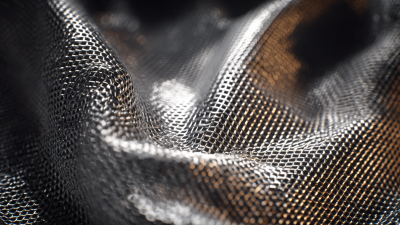

In today's competitive industrial landscape, selecting the right fine mesh metals is crucial for enhancing filtration efficiency across various applications. According to a recent report by MarketsandMarkets, the global filtration market is expected to reach $39.6 billion by 2026, driven by increasing demand for high-quality filtration solutions in industries such as food and beverage, pharmaceuticals, and oil and gas. Fine mesh metals, known for their superior mechanical strength and adaptability, play a vital role in achieving optimal filtration performance. They offer enhanced durability and resistance to corrosive elements, which is essential in maintaining operational efficiency and product integrity. As industries strive for advanced filtration solutions to comply with stringent regulatory standards and improve production processes, understanding the properties and applications of fine mesh metals becomes paramount in making informed decisions that can lead to significant cost savings and efficiency gains.

In today's competitive industrial landscape, selecting the right fine mesh metals is crucial for enhancing filtration efficiency across various applications. According to a recent report by MarketsandMarkets, the global filtration market is expected to reach $39.6 billion by 2026, driven by increasing demand for high-quality filtration solutions in industries such as food and beverage, pharmaceuticals, and oil and gas. Fine mesh metals, known for their superior mechanical strength and adaptability, play a vital role in achieving optimal filtration performance. They offer enhanced durability and resistance to corrosive elements, which is essential in maintaining operational efficiency and product integrity. As industries strive for advanced filtration solutions to comply with stringent regulatory standards and improve production processes, understanding the properties and applications of fine mesh metals becomes paramount in making informed decisions that can lead to significant cost savings and efficiency gains.

Filtration efficiency is a critical aspect of industrial processes, impacting product quality, operational efficiency, and regulatory compliance. According to a report by MarketsandMarkets, the global filtration market is projected to grow from $81.2 billion in 2020 to $109.3 billion by 2025, reflecting an increasing focus on efficient filtration solutions across various industries. Enhanced filtration efficiency not only minimizes contaminants but also reduces downtime and maintenance costs, ensuring smoother operations in sectors such as pharmaceuticals, food and beverage, and chemicals.

The choice of fine mesh metals plays a significant role in achieving optimal filtration efficiency. Materials such as stainless steel and synthetic mesh demonstrate varying degrees of resistance to corrosion and wear, which are essential for longevity and reliability in harsh industrial environments. A study published by Chemical Engineering Journal indicates that utilizing the right mesh size can lead to a filtration efficiency increase of up to 30%, significantly improving the overall performance of filtration systems. Industries must prioritize the selection of appropriate fine mesh metals to enhance their filtration processes, ultimately leading to improved product quality and operational efficiency.

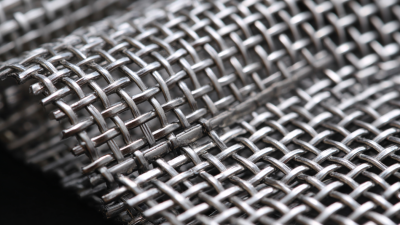

When selecting fine mesh metals for filtration purposes, understanding their key properties is essential for optimizing performance. One critical factor is the mesh size, which determines the size of particles that can pass through the filter. A finer mesh will capture smaller particles but may also restrict flow rates, potentially impacting the efficiency of the filtration process. Therefore, it’s vital to strike a balance between particle retention and fluid dynamics according to the specific needs of your industry.

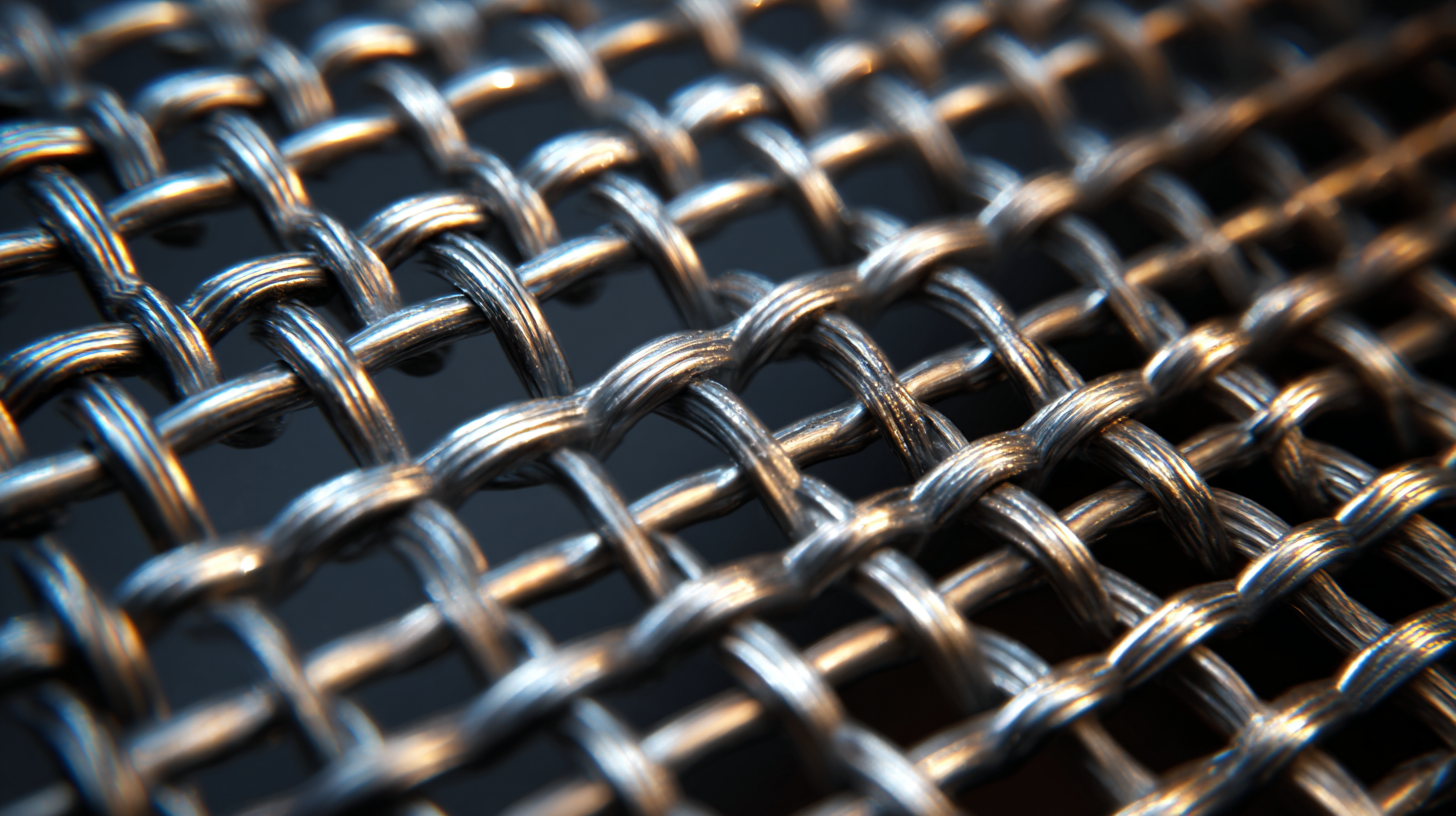

Another significant property is the material composition of the fine mesh. Different metals, such as stainless steel or nickel alloy, offer varying levels of corrosion resistance, strength, and durability under different operational conditions. For instance, stainless steel meshes are particularly suited for industries that involve aggressive chemicals or high temperatures, while lighter metals might be appropriate for less demanding applications. Additionally, factors like the opening shape and pattern can influence both the debris buildup and ease of cleaning, further enhancing filtration efficacy. Understanding these properties can lead to more informed decisions in the selection of fine mesh metals, ultimately contributing to improved operational efficiency.

| Metal Type | Mesh Size (µm) | Filtration Efficiency (%) | Corrosion Resistance | Temperature Resistance (°C) | Applications |

|---|---|---|---|---|---|

| Stainless Steel | 50 | 98 | Excellent | 800 | Food & Beverage, Chemical Processing |

| Nickel Alloy | 25 | 95 | Good | 600 | Aerospace, Marine |

| Bronze | 35 | 90 | Fair | 400 | Water Treatment, Marine |

| Titanium | 10 | 99 | Excellent | 600 | Chemical Processing, Biomedical |

| Aluminum | 40 | 85 | Moderate | 300 | Automotive, HVAC |

When selecting fine mesh metals for enhanced filtration efficiency, it's essential to compare the various types available to identify the best fit for specific applications. Different industries have unique requirements that demand tailored filtration solutions.  For instance, wire mesh embedded in natural fiber composites has shown significant promise in enhancing material properties, making it an ideal choice for sectors where lightweight and high-strength materials are crucial. These composites not only improve filtration performance but also contribute to sustainability, aligning with modern manufacturing goals.

For instance, wire mesh embedded in natural fiber composites has shown significant promise in enhancing material properties, making it an ideal choice for sectors where lightweight and high-strength materials are crucial. These composites not only improve filtration performance but also contribute to sustainability, aligning with modern manufacturing goals.

Tips for selecting the right mesh include assessing the intended application and understanding the material strengths. Evaluate the mechanical properties of various metal meshes, such as their flexibility and durability under stress. For example, aluminum wire mesh has been noted to influence the mechanical properties of hybrid composites favorably, providing a balance of strength and ductility.

Additionally, consider the mesh's environmental impact. The recent comparative studies on eco-friendly wire mesh configurations highlight the importance of sustainability in construction and manufacturing. By focusing on both performance and environmental considerations, industries can make informed choices that enhance their operational efficiency while promoting greener practices.

When selecting fine mesh metals for filtration processes, understanding the significance of mesh sizes and open area is crucial for optimizing performance. Mesh size, typically defined by the number of openings per linear inch, directly impacts the filtration efficiency. According to the Filtration Society, a mesh size between 200 to 400 microns is ideal for industries requiring high clarity in the separated materials, such as pharmaceuticals and food processing. As the mesh size decreases, the ability to capture finer particles increases, but this also raises the risk of clogging, necessitating a balance based on the specific application requirements.

Moreover, the open area of the mesh, which refers to the percentage of surface area not obstructed by the wire, plays a vital role in determining flow rates and pressure drops across the filter. Research published by the American Filtration Association indicates that an open area of 30% to 50% is generally recommended to maintain optimal fluid dynamics while ensuring effective particle removal. A larger open area facilitates higher flow rates, reducing operational pressure and energy costs, crucial for industries aiming to maximize throughput without compromising on filtration quality. Therefore, careful evaluation of both mesh size and open area is essential for achieving enhanced filtration efficiency tailored to the unique demands of each industry.

When selecting fine mesh metals for enhanced filtration efficiency, it is crucial to adhere to industry standards and best practices to ensure optimal performance. The recent Wire Mesh Fencing Manufacturing Cost Analysis Report by IMARC Group highlights the growing importance of high-quality materials, particularly in sectors such as water treatment, food processing, and chemical manufacturing. According to the report, the increasing demand for durable mesh materials correlates directly with advancements in filtration technologies, driving innovations in production techniques that enhance material strength and versatility.

Selecting the right fine mesh metal also involves understanding the specific requirements of your applications, including wire diameter, mesh openings, and materials’ corrosion resistance. For instance, stainless steel remains a preferred choice due to its excellent resistance to oxidation and rust, which is critical in industries that operate under harsh conditions. Additionally, the report indicates that raw material costs are projected to rise, emphasizing the need for industries to invest in cost-effective sourcing strategies while maintaining high filtration standards. This dual focus on quality and cost efficiency is key to achieving long-term operational sustainability in a competitive market.