No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the increasingly competitive landscape of mining and aggregates, the selection of the right Urethane Screen Mesh plays a pivotal role in maximizing screening efficiency. According to a 2023 industry report by Global Market Insights, the Urethane Screen Mesh market is expected to grow by over 20% annually, driven by the material's durability and performance in varying application conditions. As industries seek to optimize their processes, understanding the specific properties of Urethane Screen Mesh becomes essential for ensuring optimal material separation and increased throughput.

Industry expert Dr. Jane Thompson, a leading material scientist at the Institute of Screening Technology, observes, "The right Urethane Screen Mesh can significantly enhance the efficiency of separation processes. Investing in quality mesh tailored for specific materials can yield remarkable returns in productivity." Her insights highlight the importance of not only selecting a mesh based on standard specifications but also considering the unique characteristics of the materials being processed.

As we delve into the practical considerations for choosing Urethane Screen Mesh, this article aims to provide a comprehensive guide that aligns with the latest trends and technological advancements in the field, ensuring that both seasoned professionals and newcomers can make informed decisions for optimal screening outcome.

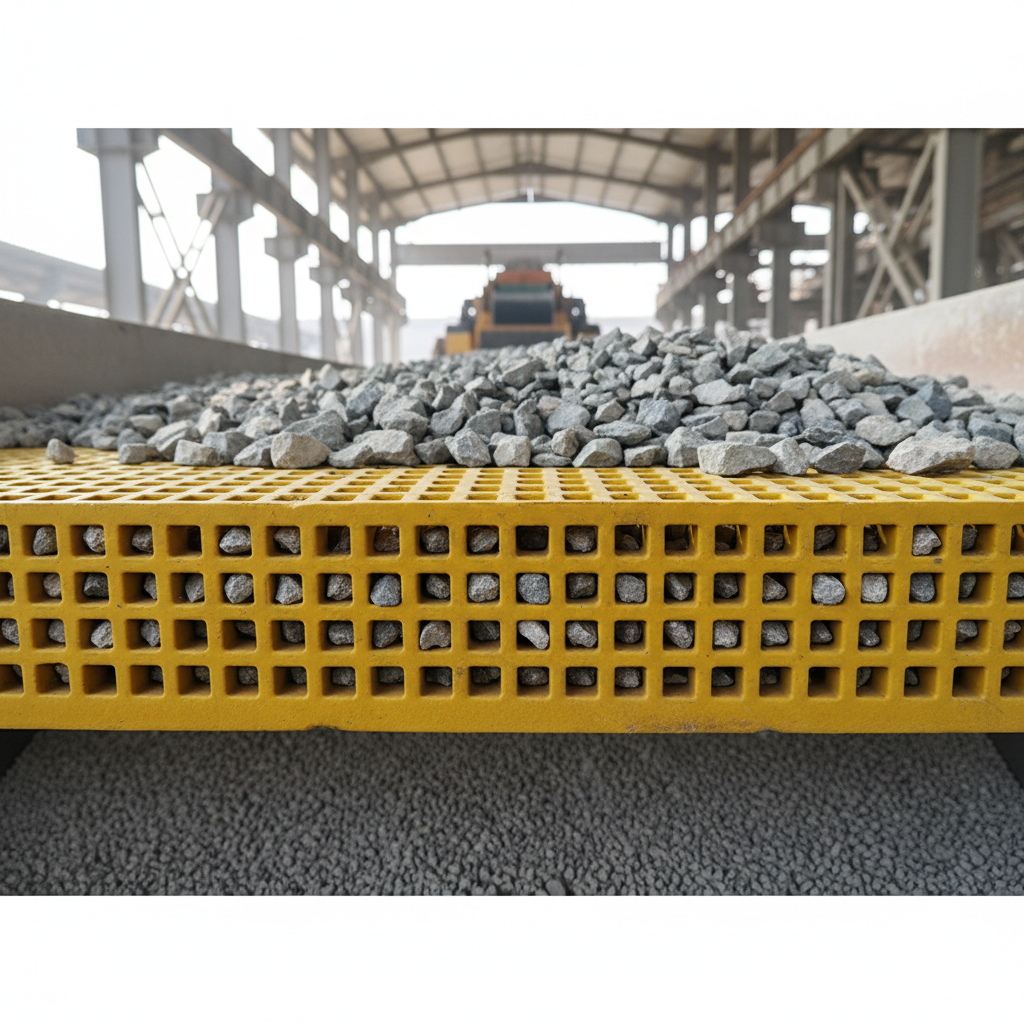

When selecting the appropriate urethane screen mesh, it's essential to understand the various types available and their specific applications. Urethane screen meshes are known for their durability and flexibility, making them ideal for various industries such as mining, aggregate, and recycling. There are several types of urethane screen meshes, including high-frequency, modular, and tensioned screens, each designed to meet specific screening needs.

High-frequency screens can efficiently separate fine materials, while modular screens offer versatility and ease of installation, allowing for quick replacements without full system overhauls.

Different applications may require distinct mesh configurations. For example, in the mining industry, urethane screens with larger openings may be preferred for aggregate separation, whereas finer meshes are critical for separating smaller particles in mineral processing.

Additionally, chemical resistance can be an important factor in environments dealing with harsh substances. Understanding these variations and their respective applications enables users to choose the right urethane screen mesh, ensuring optimal screening efficiency and increased productivity in their operations.

When selecting urethane screen mesh for optimal screening efficiency, several key factors must be considered. One of the most critical elements is the mesh's opening size, which directly influences material separation. According to a report by the Industrial Screen Manufacturer's Association, the correct mesh opening can improve production efficiency by up to 20%, ensuring that the desired particle sizes pass through while effectively retaining larger materials.

Another important consideration is the mesh's durability and resistance to wear. Urethane materials are known for their superior flexibility and longevity compared to traditional wire meshes. Research indicates that urethane screens can last up to 50% longer in high-impact applications, providing a cost-effective solution over time.

Tips: When choosing urethane screen mesh, always assess the specific application's requirements, such as the type of materials being screened and the desired throughput. Additionally, consult with manufacturers about custom mesh options that can further enhance performance based on your unique operational needs. Remember, investing in high-quality urethane screens can lead to considerable increases in both product quality and overall processing efficiency.

When it comes to selecting the right urethane screen mesh, understanding mesh size and open area is crucial for achieving optimal screening efficiency. Different applications require varying levels of fineness and flow rate, which are determined by the mesh size. A smaller mesh size may help in capturing finer materials, but it can also restrict flow and reduce operational efficiency. Conversely, a larger mesh size allows for increased throughput but may lead to a loss of separation accuracy. Therefore, finding the right balance is key to maximizing performance.

Tips: When assessing mesh size, consider not only the material you are screening but also the specific requirements of your equipment. Testing the mesh in real-world conditions can provide valuable insights into its performance. Don't overlook the importance of open area; a mesh with a higher open area percentage facilitates better material flow and efficiency. Aim for a mesh design that optimizes both mesh size and open area for enhanced operational performance.

Additionally, consider the material and durability of the urethane screen mesh. High-quality materials can withstand wear and tear while maintaining their shape and mesh openings. Regular maintenance and monitoring can also ensure that the mesh continues to perform at its best, adapting to any changes in the material composition or screening environment.

When selecting urethane screen mesh for screening applications, assessing durability and resistance features is critical for ensuring optimal performance. Urethane mesh is widely recognized for its superior abrasion resistance compared to traditional wire mesh. According to a report by the Mining & Quarrying Journal, urethane screens can last up to three times longer than their wire counterparts, thereby significantly reducing replacement frequency and associated costs. This increased longevity makes urethane a preferred choice in high-impact applications where maintenance downtime can severely affect productivity.

In addition to abrasion resistance, the chemical compatibility of urethane mesh is essential to enhance its operational lifespan. Studies conducted by the International Journal of Material Science indicate that urethane exhibits excellent resistance to a variety of acids, alkaline solutions, and solvents, making it suitable for diverse industrial applications, from mineral processing to wastewater treatment. This resilience enables urethane screens to perform efficiently even in harsh environments, allowing for consistent screening efficiency while minimizing material degradation.

Maintaining urethane screening equipment is crucial for ensuring optimal efficiency and longevity. Regular inspections should be conducted to check for wear and tear on the mesh. This includes looking for signs of fraying, tears, or any blockage that can hinder the screening process. Cleaning the screens regularly with a gentle brush or low-pressure water can help prevent the buildup of materials that might affect performance. It is essential to follow the manufacturer's guidelines for cleaning to avoid damaging the urethane material.

In addition to routine inspections and cleaning, proper storage of urethane screens is vital. When not in use, screens should be stored in a cool, dry place away from direct sunlight and extreme temperatures. This prevents degradation of the urethane material, which can occur due to prolonged exposure to harsh conditions. Furthermore, using the correct installation techniques when placing screens on screening equipment can prevent unnecessary stress and prolong their life. By adhering to these maintenance tips, operators can ensure their urethane screening equipment runs efficiently and effectively for years to come.