No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

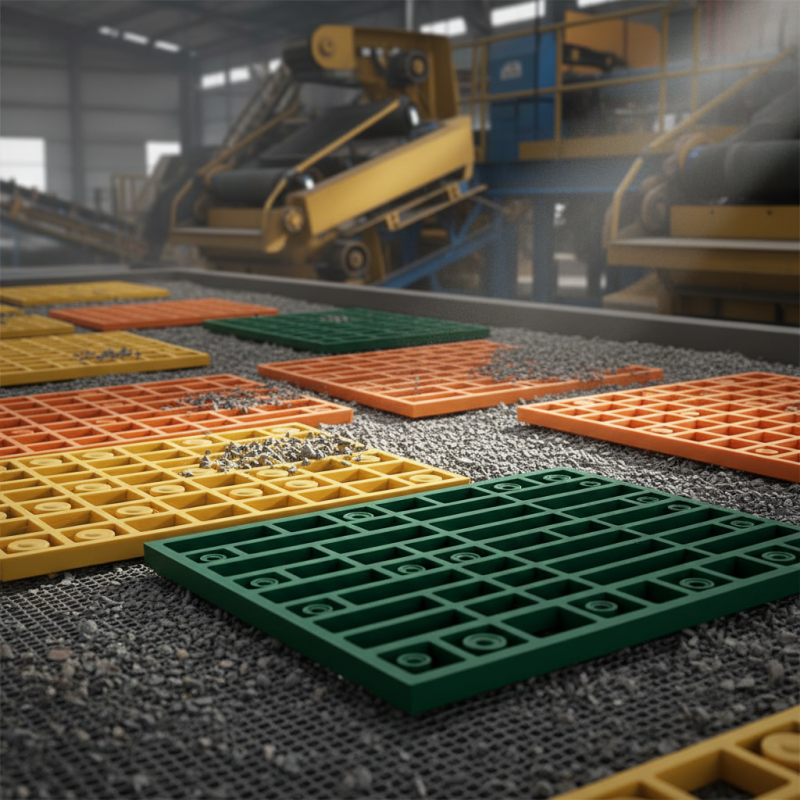

When it comes to optimizing your screening processes, selecting the right materials is crucial for efficiency and performance. Urethane Screen Mesh has emerged as a favored choice among industries demanding high-quality screening solutions. Known for its durability, versatility, and resistance to wear, urethane mesh offers significant advantages over traditional screening media. However, choosing the best Urethane Screen Mesh for your specific screening needs requires careful consideration of several factors, including application type, mesh size, and environmental conditions.

Understanding the unique properties of Urethane Screen Mesh can help you make informed decisions that enhance overall productivity. The mesh's design can significantly affect material flow, separation efficiency, and minimal blinding, making it essential to match the right mesh type with your operational requirements. Additionally, factors such as load capacity and flexural strength come into play, influencing the longevity and effectiveness of your screening systems. As you navigate the various options available, having a clear understanding of your specific needs will empower you to select a Urethane Screen Mesh that not only meets but exceeds your expectations.

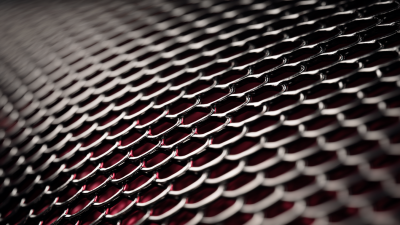

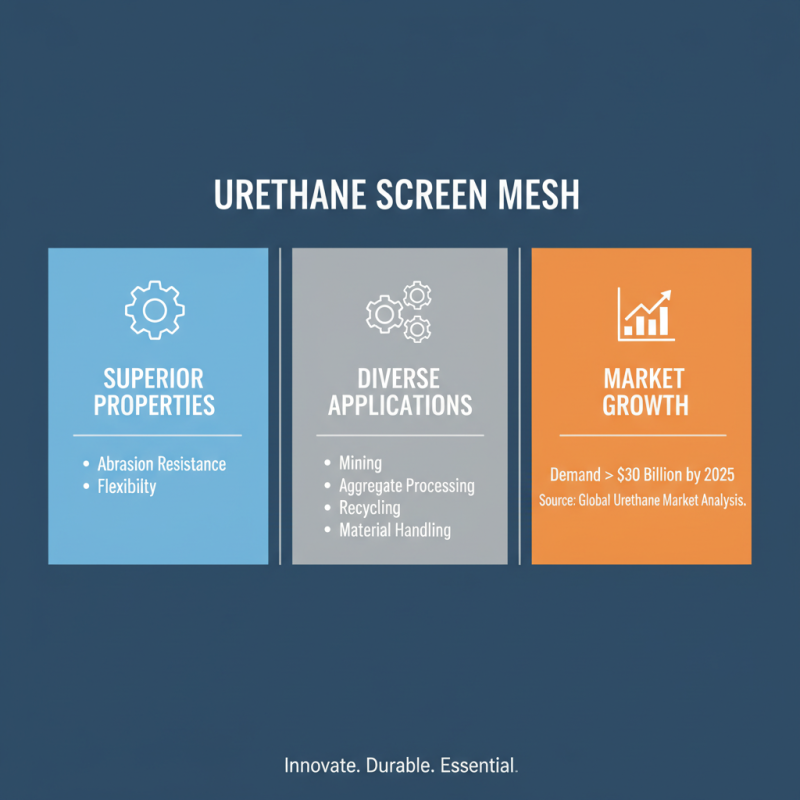

Urethane screen mesh has gained significant traction in various industries due to its unique properties and versatility. Unlike traditional materials, urethane offers superior abrasion resistance and flexibility, making it ideal for diverse applications such as mining, aggregate, and recycling. According to a report by the Global Urethane Market Analysis, the demand for urethane materials is projected to reach over $30 billion by 2025, highlighting its growing prevalence in material handling applications.

One of the key advantages of urethane screen mesh is its capacity to withstand harsh operating conditions. Data from the Mining Industry Report states that urethane screens can last up to three times longer than their steel counterparts in abrasive environments, reducing downtime and maintenance costs for operators. Urethane's ability to effectively separate materials while minimizing blinding and pegging ensures optimal performance in screening processes. Furthermore, its lightweight nature facilitates easier installation and adjustments, enhancing overall operational efficiency.

Overall, the advantages of urethane screen mesh are aligned with the industry's push towards more durable and efficient screening solutions. Understanding the specific applications and performance metrics of urethane can help companies make informed decisions, ensuring they choose the right mesh for their operational requirements. With ongoing advancements and innovations, urethane is firmly establishing itself as a cornerstone material in the industry.

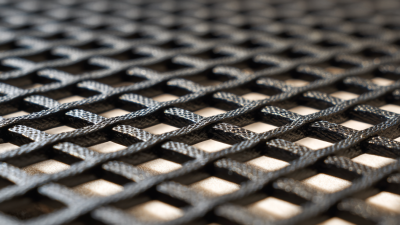

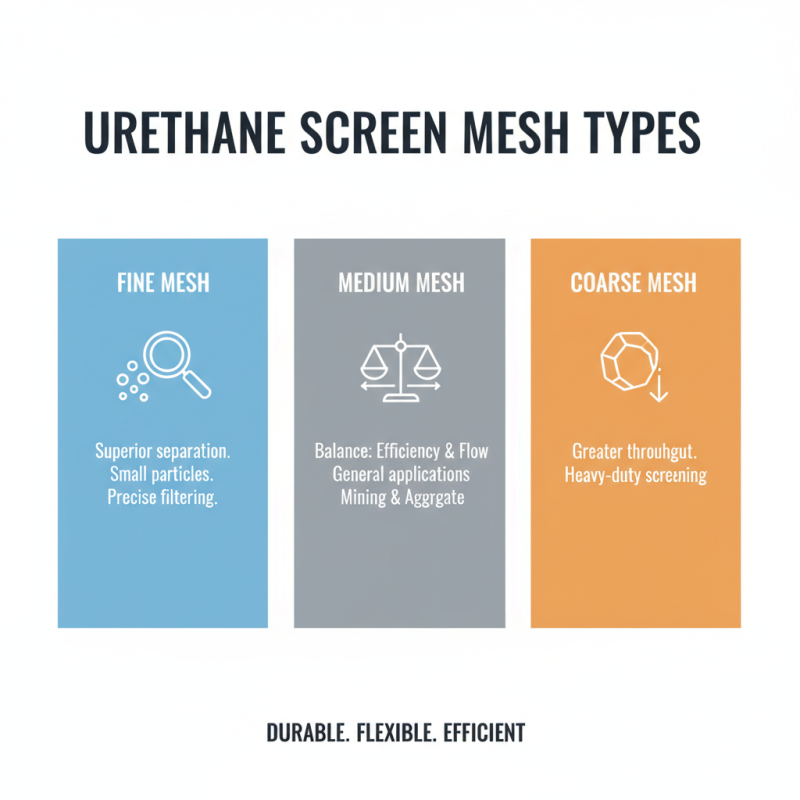

When selecting urethane screen mesh for your screening needs, one of the crucial factors to consider is the mesh size. The mesh size determines the particle size that can pass through the screen, directly impacting the efficiency of the screening process. It's essential to match the mesh size to the specific materials you are processing. A finer mesh may be necessary for smaller particles, while larger particles require coarser mesh. Additionally, consider the application environment; high abrasion or corrosive conditions may necessitate a stronger mesh with enhanced durability.

Another key factor is the durometer, which measures the hardness of the urethane material. A higher durometer typically offers increased wear resistance, making it suitable for heavy-duty applications where impact and wear are prevalent. Conversely, a softer durometer may provide better flexibility and resistance to tearing, which can be beneficial for applications involving softer materials. Understanding the balance between hardness and flexibility will help you select a urethane screen mesh that meets your specific operational requirements, thereby optimizing the performance and longevity of your screening system.

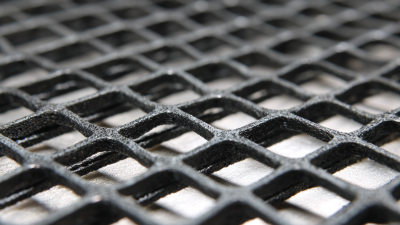

When choosing the best urethane screen mesh for your screening needs, it's essential to consider the various types available on the market. Urethane screen mesh is known for its durability and flexibility, making it a preferred choice for many industries. The main types include fine mesh, medium mesh, and coarse mesh, each designed for specific applications. Fine mesh offers superior separation for smaller particles, making it ideal for precise filtering processes. Medium mesh provides a balance between screening efficiency and flow rate, suitable for general applications in mining and aggregate industries. Coarse mesh allows for greater material throughput and is often used in processes requiring heavy-duty screening.

Additionally, the flexibility of urethane screen mesh allows for customization in size and shape, catering to different operational requirements. Some variants of urethane mesh are designed with enhanced wear resistance, prolonging their lifespan in high-impact environments. It is also worth noting that some mesh types incorporate unique surface textures to improve material flow and reduce blinding, which can significantly enhance screen performance. Understanding these different types and their characteristics will help you select the most appropriate urethane screen mesh to meet your specific screening application needs.

When selecting urethane screen mesh for specific screening applications, evaluating its durability is paramount. Urethane is known for its superior resistance to wear and tear compared to traditional materials like wire or nylon. This durability translates into longer service life, meaning that investments in urethane screens can yield significant cost savings over time. Factors such as abrasion resistance and the ability to withstand high impact should be carefully considered. Additionally, understanding the operating conditions, such as temperature fluctuations and exposure to various chemicals, is crucial for ensuring that the selected mesh performs optimally under specific conditions.

Performance is equally important when assessing urethane screen mesh. This involves analyzing various factors, including the mesh's opening size, tensioning capabilities, and overall design, which can greatly influence the effectiveness of the screening process. A properly designed urethane screen mesh will not only facilitate efficient material separation but also maintain structural integrity under high loads. Evaluating the screen's performance can include testing its throughput capacity and efficiency in different applications, ensuring that it meets the specific requirements of the operation. Proper selection based on durability and performance criteria will lead to improved productivity and reduced downtime in screening operations.

Proper maintenance of urethane screen mesh can significantly extend its lifespan and enhance screening efficiency. One essential tip is to regularly inspect the mesh for signs of wear or damage. Checking for tears, abrasion, or deformations allows you to address issues before they compromise the screen's performance. It's advisable to conduct visual inspections weekly, especially in high-usage environments.

Another critical aspect of maintenance is cleaning the urethane mesh. Build-up of materials can lead to reduced screen effectiveness and premature wear. Depending on your screening material, use appropriate cleaning solutions and techniques to remove any residue without causing damage to the mesh. Regular cleaning not only maintains screening efficiency but also helps identify any potential issues before they escalate.

Lastly, always consider the operating conditions where the screen mesh is utilized. Excessive vibration, high-temperature materials, or challenging environmental conditions can all impact the longevity of the mesh. By adjusting the operating parameters and ensuring that the screen is installed correctly, you can prevent unnecessary stress and enhance its durability.

| Screen Type | Mesh Size (microns) | Material Thickness (mm) | Application | Maintenance Tip |

|---|---|---|---|---|

| Standard Urethane | 200 | 5 | General Screening | Regular Cleaning |

| High Abrasion Urethane | 100 | 6 | Mining | Inspect for Wear |

| Fine Urethane | 50 | 4 | Sand Screening | Avoid Heavy Impacts |

| Coarse Urethane | 300 | 7 | Gravel | Shield from Sunlight |

| Chemical Resistant Urethane | 150 | 5 | Chemical Processing | Rinse After Use |