No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

Choosing the right materials for your projects is crucial. Fine Mesh Metals can offer both functionality and aesthetic appeal. They are lightweight and durable, which makes them ideal for various applications. However, not all fine mesh metals are created equal. Some metals may corrode or deteriorate over time, which can lead to unforeseen issues.

When selecting fine mesh metals, consider the purpose of your project. Are you using it for filtration, decoration, or structural support? Each application may require different properties. The size of the mesh and the metal type also play significant roles. For instance, stainless steel may withstand moisture better than aluminum.

Take your time during the selection process. It is easy to overlook details like the weave pattern or the thickness of the material. These factors can significantly impact performance. Reflect on your choices, and don’t rush; refining your material selection will enhance your project's overall success.

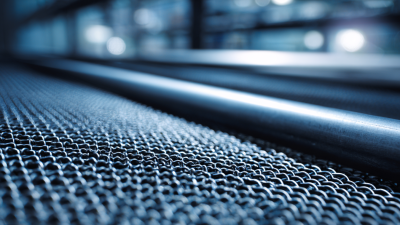

Fine mesh metals are essential in various applications, from filtration to structural reinforcement. Understanding the types and properties of fine mesh metals is crucial for making informed choices. Metals such as stainless steel, aluminum, and copper offer unique benefits. Stainless steel mesh provides excellent corrosion resistance, making it ideal for outdoor and industrial applications. Aluminum mesh, while lightweight, exhibits good strength and conductivity, suitable for electrical projects. Copper is valued for its conductivity and antimicrobial properties, often used in medical applications.

When selecting fine mesh metals, consider the mesh size and opening dimensions. A smaller opening size generally increases filtration capability but may reduce airflow. Projects requiring high precision need specific mesh densities. According to industry data, a smaller mesh size could provide filtration efficiencies exceeding 99%. However, achieving such performances comes with trade-offs in terms of airflow and weight.

Tips: Always assess the environment of use. Factors like humidity and temperature can affect metal performance. Also, think about the project scale. Larger projects may benefit from bulk mesh options. Weigh the pros and cons of each metal type carefully, as one may not fit all situations. Choosing the right material often requires multiple iterations and adjustments. Remember, fine mesh metals do not come with a one-size-fits-all solution.

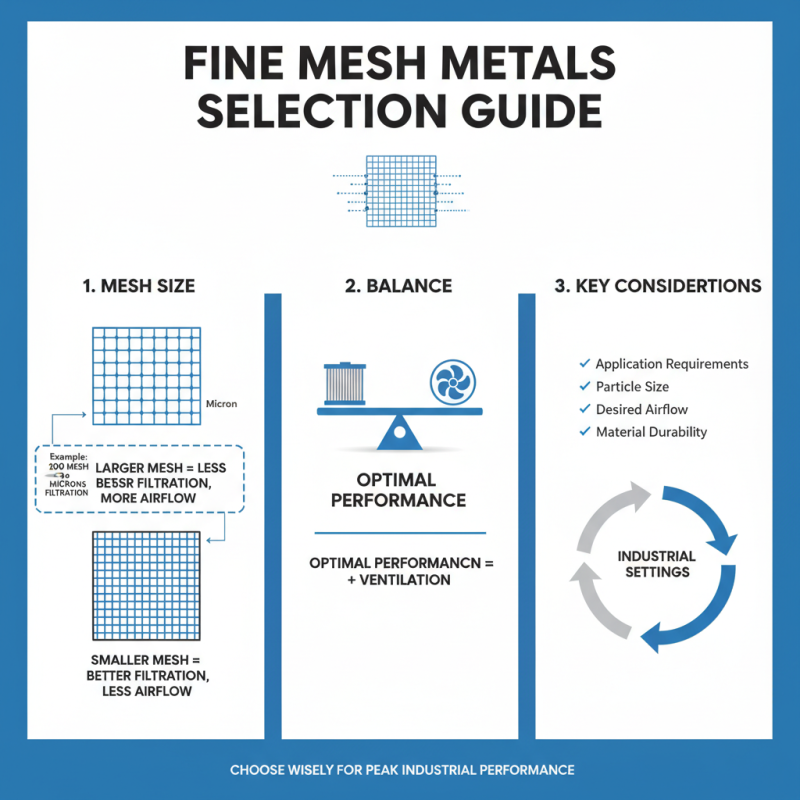

When choosing fine mesh metals, several critical factors need consideration. Mesh size is paramount. A smaller mesh size offers better filtration but may reduce airflow. For instance, a 200 mesh can filter particles down to 74 microns, making it suitable for precision tasks. The right balance between filtration and ventilation ensures optimal performance in industrial settings.

Material composition also plays a vital role. Stainless steel is popular for its durability and resistance to corrosion. On the other hand, aluminum mesh is lightweight and cost-effective. Reports show that industries using aluminum have seen a 30% reduction in weight, which can significantly impact project feasibility. Think about the long-term use and potential environmental factors.

Lastly, consider the manufacturing process. Some meshes undergo welding, while others are woven. Welded mesh typically offers greater strength but may not be as flexible. Flexibility can be crucial depending on the application. An industry report notes that 15% of project failures are linked to unsuitable mesh choices. Reflecting on these aspects can lead to better decision-making.

Fine mesh metals have diverse applications across various industries. In construction, they can be used for reinforcing concrete, providing both durability and strength. In the medical field, fine mesh metals serve as filters in various devices, ensuring safety and reliability. Food processing also employs fine mesh for sieving and filtering, maintaining hygiene standards and product quality.

When selecting fine mesh metals, consider the specific requirements of your project. Different applications may require varying levels of corrosion resistance and tensile strength. Take time to assess the environment in which the mesh will be used. Are there high levels of moisture or chemicals? These factors affect material choice.

Tip: Always request samples before making a large purchase. Testing durability and compatibility in real conditions can save you from future hassle. Pay attention to the sizing of mesh openings as well. Too small or too large openings can lead to unsatisfactory results. Reflect on your project's needs carefully, as improper choices can lead to failures.

Maintaining fine mesh metal projects requires attention to detail. Regular cleaning is essential to prevent rust and corrosion. Use a soft brush to gently remove dirt and debris. This simple act can prolong the lifespan of your project. Be aware of the environment your metal is in. Humidity and temperature changes can affect its integrity.

Inspect your fine mesh projects periodically. Look for signs of wear, such as frayed edges or discoloration. Address these issues promptly. A little maintenance goes a long way. Sometimes, a neglected project becomes an eyesore. Consider applying a protective coating. This can significantly reduce wear and tear.

Keep in mind that even the best metals can fail without care. Reflect on your maintenance routine. Are you doing enough? Regular checks can make a difference. Remember to store your items properly when not in use. Proper storage helps maintain quality over time.

Choosing fine mesh metals for your projects requires careful consideration. Start by identifying the specific needs of your project. Is it for filtration, reinforcement, or as a decorative element? Each use demands different properties. The mesh size is crucial. Finer meshes can provide better filtration, while coarser meshes may offer more strength.

When sourcing quality fine mesh metals, inspect the material closely. Look for uniformity in the weave. An inconsistent pattern may indicate poor craftsmanship. Check for any visible defects. Scratches or dents can compromise functionality. Also, think about the metal type. Stainless steel is common for its durability, but aluminum is lighter and more corrosion-resistant.

Beware of the supplier's reputation. Not all vendors adhere to high standards. Sometimes, the best deal might end up costing more in the long run. Collect samples when possible. Feel the material and test its flexibility and strength. This hands-on approach provides insight that images can't. It’s easy to get lost in technical specifications, but personal evaluation can help you avoid costly mistakes.

| Mesh Type | Material | Opening Size (microns) | Wire Diameter (mm) | Strength Rating | Common Applications |

|---|---|---|---|---|---|

| Woven Mesh | Stainless Steel | 200 | 0.25 | High | Filtration, Food Processing |

| Perforated Sheet | Aluminum | 500 | 0.50 | Moderate | Architectural, Sound Dampening |

| Expanded Metal | Mild Steel | 1000 | 1.00 | Low | Walkway Grating, Decorative Screens |

| Micro Mesh | Nickel Alloy | 50 | 0.10 | Very High | Aerospace, Electronics |