No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

When embarking on a project that requires the selection of an MDI PU Tension Screen, the decision can significantly impact the overall success and performance of your undertakings. According to industry expert Dr. John Stevens, a leading authority in screen technology, “Choosing the right MDI PU Tension Screen is pivotal in maximizing efficiency and ensuring long-lasting durability.” This statement underscores the importance of understanding the intricacies involved in selecting the appropriate screen for various applications.

As projects vary in scope and requirements, the factors to consider when choosing an MDI PU Tension Screen can be daunting. It’s crucial to assess the specific needs of your project, such as material compatibility, screen tensioning systems, and environmental conditions. By carefully evaluating these elements, project managers can make informed decisions that not only meet performance expectations but also align with budget constraints. Ultimately, the right choice in MDI PU Tension Screens can lead to enhanced operational efficiency and a successful project outcome.

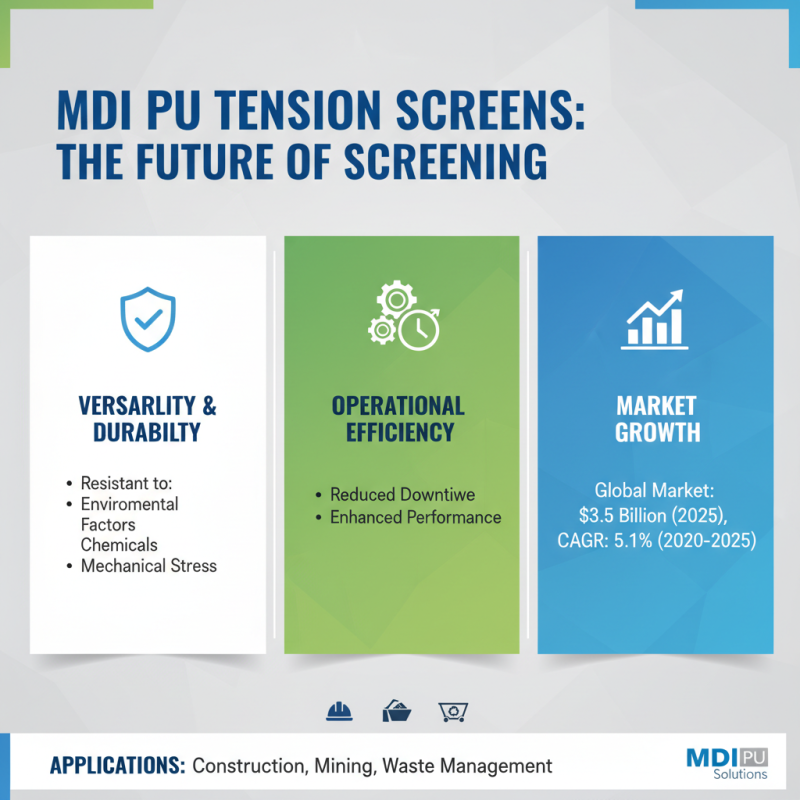

MDI PU tension screens are gaining popularity due to their versatility and durability across various applications. These screens, made from methylene diphenyl diisocyanate (MDI) polyurethane, offer superior resistance to environmental factors, chemical exposure, and mechanical stress. According to a recent industry report by MarketsandMarkets, the global market for polyurethane screening solutions is expected to reach USD 3.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.1%. This growth indicates an increasing recognition of the advantages these screens provide in enhancing operational efficiency and reducing downtime in numerous industries, including construction, mining, and waste management.

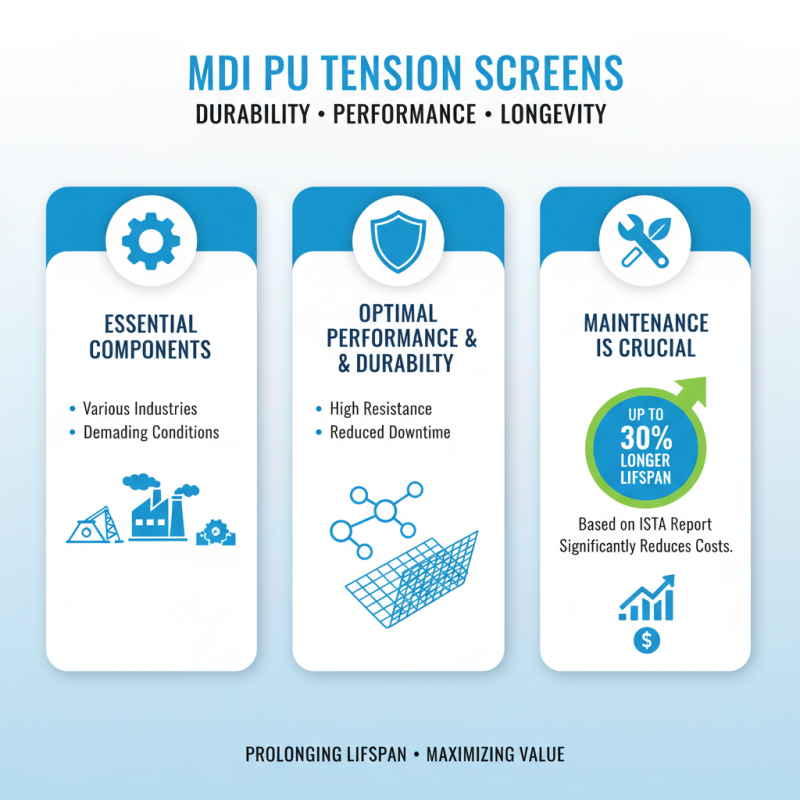

One of the notable applications of MDI PU tension screens is in the mineral processing sector, where they play a crucial role in the separation of materials. The ability to withstand high loads and resist abrasion makes them particularly effective in environments where traditional screening solutions may fail quickly. A study published in the Journal of Material Science & Engineering reveals that MDI PU screens can extend service life by up to 30% compared to conventional materials. This enhanced durability translates into lower replacement costs and less frequent maintenance, making them an attractive choice for project managers seeking reliable and long-lasting screening solutions. Furthermore, their lightweight nature allows for easier installation, significantly reducing labor costs during setup.

When selecting MDI PU tension screens for your project, there are several key factors to consider that can significantly affect performance and longevity. First, assess the specific requirements of your application, including the type of materials being worked with and the environment in which the screens will be used. Different materials may require screens with varying levels of tensile strength and flexibility. Understanding these needs will guide you in selecting the right product that maximizes efficiency and productivity.

It's also essential to evaluate the screen's installation and maintenance requirements. Look for designs that facilitate easy setup and require minimal upkeep, as this will save time and reduce operational costs in the long run. Additionally, consider the available options for customization, which can help tailor the screens to meet your project's unique demands.

**Tips:** Always request samples before making a bulk purchase, as this allows you to test the screen’s performance firsthand. Investigate the warranty and support options provided, as a strong backing can be invaluable in case of any issues. Stay informed about the latest advancements in screen technology to ensure you're making the most informed decision possible.

When choosing the right MDI PU tension screen for your project, it’s essential to compare various types available on the market. MDI PU screens are primarily categorized by their material composition and construction methods, affecting durability, flexibility, and application suitability. According to a recent industry report by Grand View Research, the global tension screen market is forecasted to grow at a CAGR of 5.3% from 2021 to 2028, driven by the increasing demand for efficient filtration solutions across various industries.

Different types of MDI PU tension screens can also be distinguished by their tensioning systems. Some utilize advanced mechanical tensioning methods, providing superior stability and uniformity. A study conducted by the International Journal of Filter Technology found that screens with enhanced tensioning mechanisms demonstrated a 15% improvement in material flow efficiency compared to standard designs. Additionally, adaptability in harsh environments plays a significant role—screens specifically designed for high abrasion resistance are critical in mining and aggregates, where wear and tear significantly impact operational costs. Evaluating these differences will ensure that you select a screen that not only meets the demands of your project but also optimizes performance and longevity.

When selecting the best MDI PU tension screen for your project, it's essential to evaluate various performance metrics that can significantly impact efficiency and durability. Key metrics to assess include tension strength, resilience to harsh environmental conditions, and overall mesh stability. Tension strength determines the screen's ability to maintain its form under pressure, while resilience informs you how well the screen can withstand elements like UV exposure, moisture, and chemical contact. It's crucial to choose a screen that balances these aspects to ensure optimal performance for your specific application.

Tip: Always consider conducting a stress test on samples of MDI PU tension screens before making a final selection. This can help gauge their performance under real-world conditions and ensure they've been designed to meet your project needs.

Another critical metric to review is the screen's maintenance requirements. Some materials may necessitate more frequent upkeep, leading to higher long-term costs. Assessing how easy it is to clean and repair the screen can provide insight into its longevity and practicality for your project. A low-maintenance option can save you time and resources down the line, allowing for a smoother and more efficient process.

Tip: Consult with industry professionals to gather insights on the maintenance aspects of different MDI PU tension screens. Their experiences can guide you to make informed choices that align with your project timelines and budget.

MDI PU tension screens are essential components in various industries, providing durability and optimal performance under demanding conditions. To prolong the life of these screens, regular maintenance is crucial. According to a report by the International Society for Technology in Agriculture, proper care can extend the lifespan of tension screens by up to 30%, reducing replacement costs significantly for businesses.

One key maintenance tip is to regularly inspect the screen for signs of wear or damage. Early detection of issues such as tears or sagging can prevent further deterioration and ensure the screen operates efficiently. Additionally, cleaning the screens routinely can help maintain their effectiveness. A study from the Materials Research Society highlights that accumulated debris can reduce screening efficiency by up to 25%, emphasizing the importance of consistent upkeep.

Another critical aspect of maintenance is monitoring the tension. Maintaining the correct tension level not only enhances screening quality but also reduces the risk of premature failure. Industry standards recommend checking tension levels weekly, particularly in high-stress applications. By implementing these maintenance strategies, users can significantly enhance the performance and longevity of their MDI PU tension screens, ensuring they meet project needs effectively.