No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the evolving world of industrial equipment, the significance of choosing the right MDI PU screen panel cannot be overstated. As John Smith, a leading expert in the field of polyurethane technology, aptly stated, "Selecting the appropriate MDI PU screen panel is crucial for optimizing performance and ensuring longevity in operations." The complexities surrounding these panels can be overwhelming, particularly when considering the diverse applications they serve across various industries.

Understanding the specific requirements of your process is essential. MDI PU screen panels come in various specifications tailored to different operational demands, from construction to manufacturing sectors. This introduction will explore key factors to consider when selecting the ideal MDI PU screen panel, such as material properties, durability, and compatibility with existing equipment. By equipping yourself with the right knowledge, you can make informed decisions that enhance productivity and achieve long-lasting results for your projects.

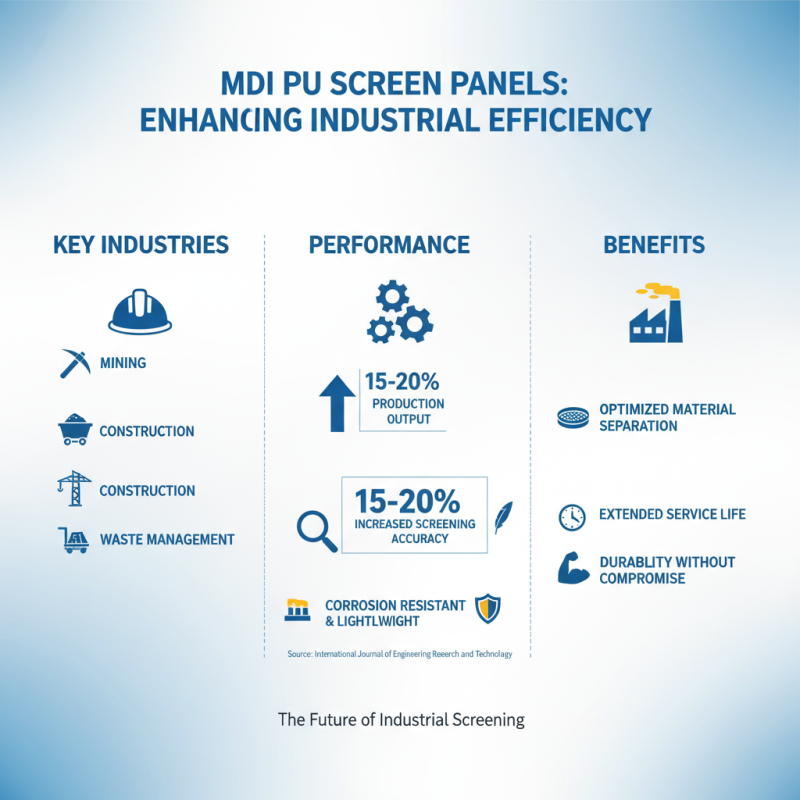

MDI PU screen panels have become essential in various industries, particularly in mining, construction, and waste management. These panels are specifically designed to separate materials by size, optimizing operational efficiency. According to a report by the International Journal of Engineering Research and Technology, the adoption of polymer-based screen panels has led to increased screening accuracy, resulting in a 15-20% improvement in production output compared to traditional metal panels. The ability of MDI PU panels to withstand corrosive environments while maintaining lightweight properties makes them a favorable choice for operations that require durability without compromising on performance.

Furthermore, MDI PU screen panels are highly versatile in their applications. Their engineered materials allow for a variety of mesh sizes, catering to different screening needs from coarse aggregates to fine particles. A recent industry analysis indicated that the global market for polyurethane screen panels is projected to grow significantly, with expectations of reaching a compound annual growth rate (CAGR) of 6.5% through 2025. This surge is attributed to the growing demand for efficient waste separation processes and the need for sustainable mining practices. As industries continue to recognize the benefits of MDI PU panels, their applications will expand, paving the way for innovative screening solutions in complex environments.

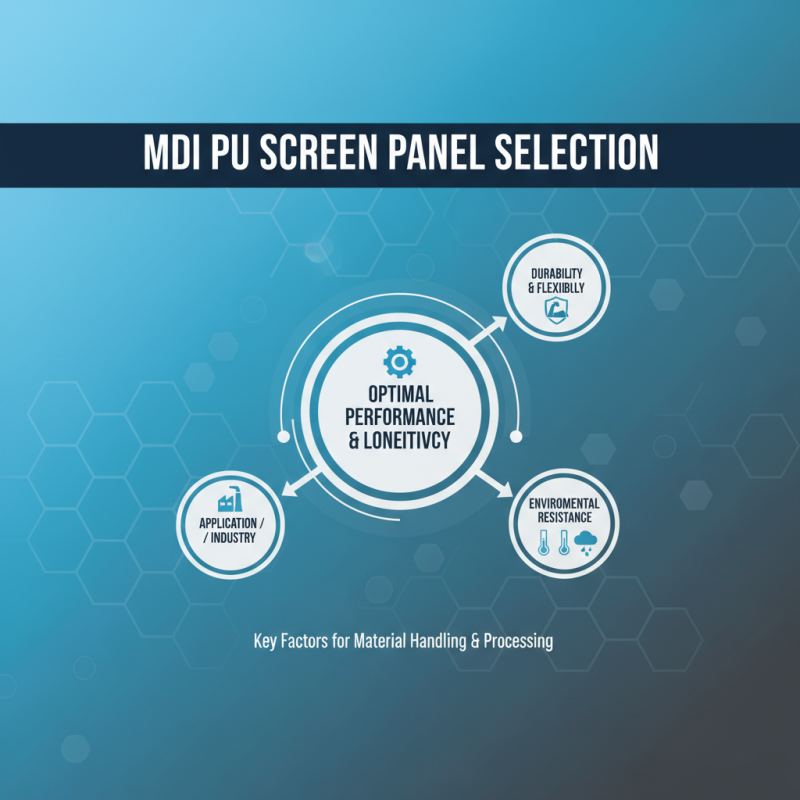

When selecting the appropriate MDI PU screen panels, several critical factors need to be considered to ensure optimal performance and longevity. First and foremost, the specific application of the screen panels plays a significant role in the selection process. Different industries and conditions demand varying levels of durability, flexibility, and resistance to environmental factors such as chemicals, temperature, and humidity. Understanding the working environment will guide users in choosing a panel that can withstand these conditions effectively.

Another important aspect to consider is the panel's design and material composition. MDI PU panels are known for their versatility, but their design can vary in terms of thickness, pore size, and structural integrity. Such variations can impact efficiency in filtration and material processing. It is essential to assess the size and nature of the materials being screened, as well as the desired throughput. By aligning these characteristics with the right panel specifications, users can enhance operational efficiency and reduce maintenance needs. Additionally, evaluating suppliers and their quality assurances can further ensure a reliable choice, adding another layer of confidence in the final decision.

When selecting the appropriate MDI PU screen panel, it's essential to compare the various types available to meet your operational requirements. Different types of MDI PU panels cater to specific applications, such as heavy-duty use in harsh environments versus light-duty situations. The materials used in the construction of these panels dictate their strength, flexibility, and resistance to wear and tear. For instance, a higher density panel may provide improved durability and load-bearing capabilities, making it suitable for aggregate screening and mining applications.

Another critical factor to consider is the panel’s design and configuration. Some panels feature a modular design that allows for easy replacement, while others come in customized sizes to fit particular machinery. Additionally, the surface pattern of the screen can affect material flow and separation efficiency. Panel types like smooth, corrugated, or perforated have distinct performance characteristics that influence the quality of the screened material. Therefore, assessing the specific working conditions and desired outcomes is vital to ensure that the chosen MDI PU screen panel can deliver optimal performance and longevity in your application.

This chart compares the various types of MDI PU screen panels based on their durability, cost, and performance in different applications.

When evaluating the durability and performance of MDI PU screen panels, it is essential to understand the materials and technologies used in their construction. MDI (Methylene Diphenyl Diisocyanate) polyurethane screens are known for their remarkable resistance to wear and tear, making them suitable for various industrial applications. A recent industry report indicates that MDI PU materials can withstand up to 200% more wear compared to traditional materials, which is critical in high-impact environments. This enhanced durability ensures a longer lifespan for screen panels, ultimately reducing replacement costs and downtime for operations.

Moreover, performance metrics such as tensile strength and elasticity play a crucial role in determining the suitability of MDI PU screen panels for specific applications. Studies suggest that MDI PU panels exhibit a tensile strength of approximately 30 MPa, coupled with a remarkable elongation at break of 300%. These properties allow for greater flexibility and resilience under dynamic loads, making them ideal for mining, aggregates, and recycling sectors. As industries increasingly lean towards durable solutions, the demand for MDI PU screen panels that combine both longevity and high performance continues to rise, underscoring the importance of selecting the right panel type based on thorough performance evaluation.

When considering the purchase of MDI PU screen panels, it is crucial to establish a budget that aligns with your business needs and financial capabilities. The cost of these panels can vary significantly based on factors such as size, thickness, and the specific properties required for your application. Conducting a thorough market analysis can help you understand the average pricing and identify potential variations that may arise due to unique specifications or customization options.

In addition to the upfront costs of MDI PU screen panels, it’s essential to factor in long-term expenses that may impact your overall budget. This includes maintenance, replacement frequency, and operational efficiency. Investing in higher-quality panels may incur a greater initial expense but can lead to reduced maintenance costs and longer lifespan, ultimately resulting in savings over time. Creating a detailed cost-benefit analysis will assist you in making an informed decision that balances the immediate financial outlay with long-term value, ensuring that your investment aligns with your operational goals.

| Panel Type | Size (mm) | Weight (kg) | Estimated Cost ($) | Durability Rating | Ideal Usage |

|---|---|---|---|---|---|

| Standard Panel | 1000 x 2000 | 75 | 300 | Up to 5 years | General use |

| Heavy-Duty Panel | 1200 x 2400 | 100 | 450 | Up to 10 years | Construction, mining |

| Premium Panel | 1500 x 3000 | 85 | 600 | Up to 8 years | High wear applications |

| Lightweight Panel | 1000 x 1000 | 55 | 200 | Up to 3 years | Mobile applications |

| Custom Panel | Varies | Depends | Varies | Depends on specification | Specialized applications |