No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the evolving landscape of industrial filtration, the choice of the right MDI PU Tension Screen has become paramount for optimizing operational efficiency. According to the latest market research by the Industrial Filtration Association, the demand for high-performance tension screens has surged by 30% over the past three years, underscoring the critical role they play in various processes, from wastewater treatment to mineral processing. Selecting the appropriate MDI PU Tension Screen not only ensures compliance with industry standards but also maximizes the longevity of equipment and minimizes maintenance downtime.

Industry expert Dr. Emily Carter, a leading authority in filtration technology, emphasizes the importance of tailored solutions for specific applications, stating, "Choosing the right MDI PU Tension Screen is not just about filtration; it’s about enhancing the overall process efficiency and achieving sustainable results." With a wide range of materials and mesh sizes available, it is essential for stakeholders to carefully assess their operational requirements. This introductory guide will explore key factors to consider when selecting an MDI PU Tension Screen, ensuring that businesses are equipped to make informed decisions that align with their unique needs and challenges.

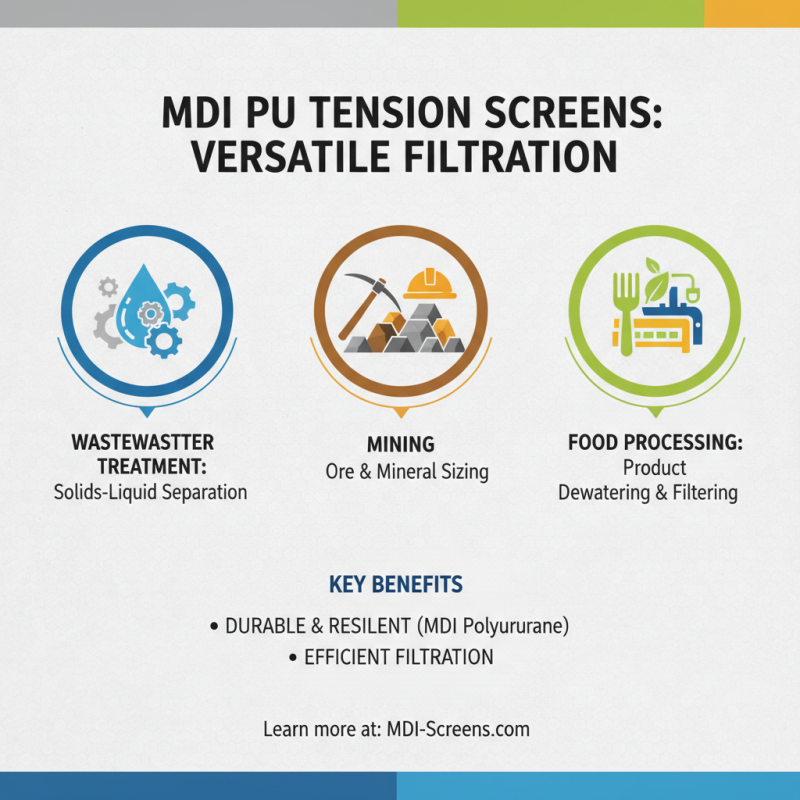

MDI PU tension screens are versatile filtration solutions widely used across various industries. Understanding the core applications of these screens is essential for selecting the right product for your specific needs. MDI, or methylene diphenyl diisocyanate, is a key component in producing polyurethane, which gives tension screens their durable and resilient characteristics. These screens are particularly effective in separating solids from liquids, making them invaluable in sectors like wastewater treatment, mining, and food processing.

When considering an MDI PU tension screen, it’s crucial to evaluate the intended application. For example, in wastewater treatment facilities, these screens help remove contaminants before the purification process, ensuring cleaner effluent. In mining operations, tension screens facilitate the separation of valuable materials from undesired waste. By tailoring your selection to the specific requirements of your industry—such as particle size, flow rate, and environmental conditions—you can maximize the efficiency and lifespan of the tension screen, meeting both operational and regulatory standards effectively.

When selecting the right MDI PU tension screen, several key factors must be considered to ensure optimal performance and longevity. First and foremost is the application environment. The screen's ability to withstand specific temperature fluctuations and chemical exposures is crucial. According to a 2022 market analysis by Global Industry Analysts, nearly 35% of screen failures can be attributed to improper material selection based on environmental conditions. Therefore, understanding the chemical compatibility and thermal limits of MDI PU is essential for achieving maximum durability.

Another critical factor is the mesh opening size. This dimension directly affects the screen's efficiency in separating particles and the overall throughput of materials. Research published in the Journal of Material Technology highlighted that screens with optimized mesh sizes can improve material flow rates by up to 20%, leading to enhanced processing efficiency. It is also important to match the mesh size with the specific material being processed, as different materials may require distinct separation capabilities based on size and density.

Lastly, the screen's tensile strength and flexibility should not be overlooked. In numerous case studies, screens made from high-quality MDI PU have demonstrated significant resistance to wear and tear, with a reported life expectancy increase of 30% over standard options. By considering these factors—environmental compatibility, mesh size, and tensile properties—users can select a tension screen that not only meets their immediate requirements but also contributes to long-term operational success.

When selecting an MDI PU tension screen, understanding the various materials and their respective thicknesses is crucial to meet your specific operational needs. MDI (Methylene Diphenyl Diisocyanate) polyurethane screens are available in multiple formulations, each impacting durability, flexibility, and wear resistance.

For instance, screens made from higher-grade materials tend to offer enhanced resistance to harsh environments while maintaining optimal tensile strength. It is important to assess the application in which the screen will be used, as different materials can perform differently depending on exposure to chemicals, UV light, and physical wear.

Thickness plays a vital role in the performance and longevity of tension screens. Thicker screens generally provide greater durability and can handle heavier loads, making them suitable for more demanding applications. Conversely, thinner screens may offer increased flexibility and reduced weight, which could be beneficial for certain polymer processing operations. Evaluating the trade-offs between thickness and material type will help you make informed decisions that align best with your operational requirements. Moreover, pay attention to how the combination of material and thickness influences the screen’s overall efficiency, as this can significantly impact your production processes.

When selecting the right MDI PU tension screen, a crucial aspect to consider is its compatibility with your existing machinery. Different machines may have unique specifications, demands, and operational limits, which dictates the need for a tailored tension screen. To ensure seamless integration, it is essential to evaluate the tension screen's dimensions, weight, and installation requirements relative to your equipment. Precise measurements guarantee that the screen functions optimally without causing disruptions during regular operation.

Moreover, understanding the operational characteristics of your machinery can inform your choice of tension screen material and design. For instance, if your equipment experiences high-frequency vibrations or significant material flows, a tension screen that can withstand these conditions without compromising performance is vital. Additionally, assessing how the tension screen interacts with the material being processed can enhance efficiency and prolong the life of both the screen and the machinery. Ultimately, a thoughtful evaluation of compatibility can significantly impact operational efficiency and maintenance costs.

Proper maintenance of MDI PU tension screens is essential for optimizing performance and extending their operational lifespan. According to a report by the Industrial Screen Manufacturers Association (ISMA), the average lifespan of a tension screen can be significantly impacted by how well it's maintained, with regular upkeep potentially increasing its longevity by up to 30%. Key maintenance practices include regular cleaning to remove debris and prevent clogging, which can diminish screen efficiency and lead to premature wear.

Additionally, maintaining the correct tension is critical. A study from the Engineering and Industrial Research Bureau indicated that improper tension can lead to screen distortion and eventual failure. Operators are encouraged to conduct regular inspections of the screen's tension and adjust it as necessary to ensure it remains within the optimal range. Furthermore, environmental factors such as humidity and temperature can affect the material properties of the MDI PU, so monitoring these factors and making adjustments in your maintenance routine can drastically influence the screen's performance and durability. By consistently adhering to these maintenance tips, users can ensure their MDI PU tension screens continue to perform effectively over time.