No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

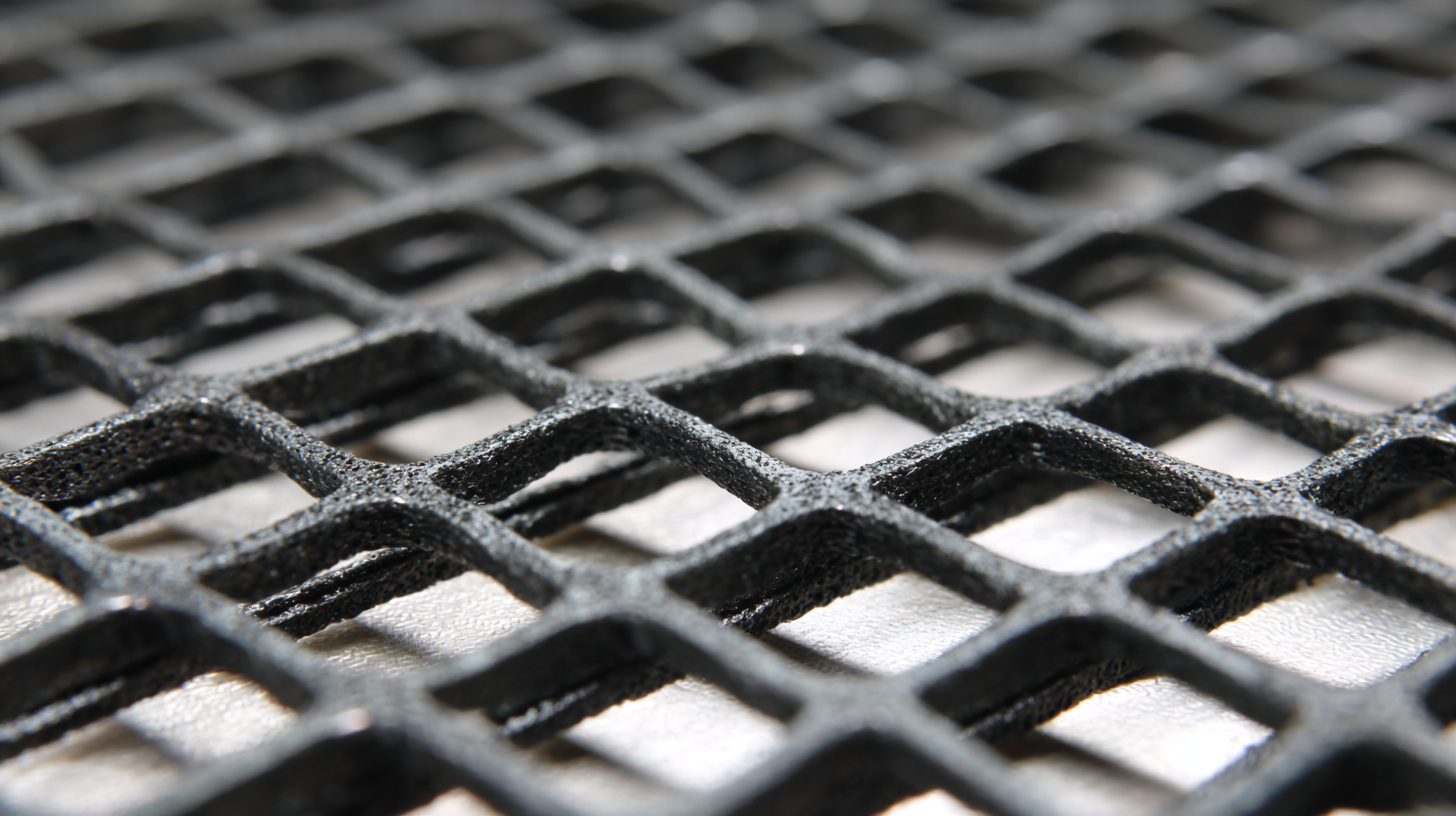

In the realm of industrial applications, the importance of selecting the right materials cannot be overstated, particularly when it comes to screening solutions. One crucial component that often makes a significant impact on operational efficiency is the Urethane Screen Mesh. Known for its durability, flexibility, and resistance to abrasion, urethane mesh is widely used across various industries, including mining, aggregate, and recycling. However, with numerous options available in the market, choosing the appropriate type can be overwhelming for manufacturers and operators alike. This blog aims to guide you through the essential factors to consider when selecting Urethane Screen Mesh, ensuring that you make informed decisions that cater to your specific industrial needs. By understanding the characteristics and applications of different mesh types, you can enhance productivity and reduce downtime in your operations.

When selecting urethane screen mesh for industrial applications, several key factors must be considered to ensure optimal performance and longevity. First, it’s essential to evaluate the specific materials being processed. Different meshes offer varying levels of abrasion resistance and flexibility, making it crucial to choose one that aligns with the type of materials, whether they be aggregates, minerals, or chemicals.

Tip: Always consult with manufacturers regarding the compatibility of the urethane screen mesh with your materials to prevent premature wear or failure.

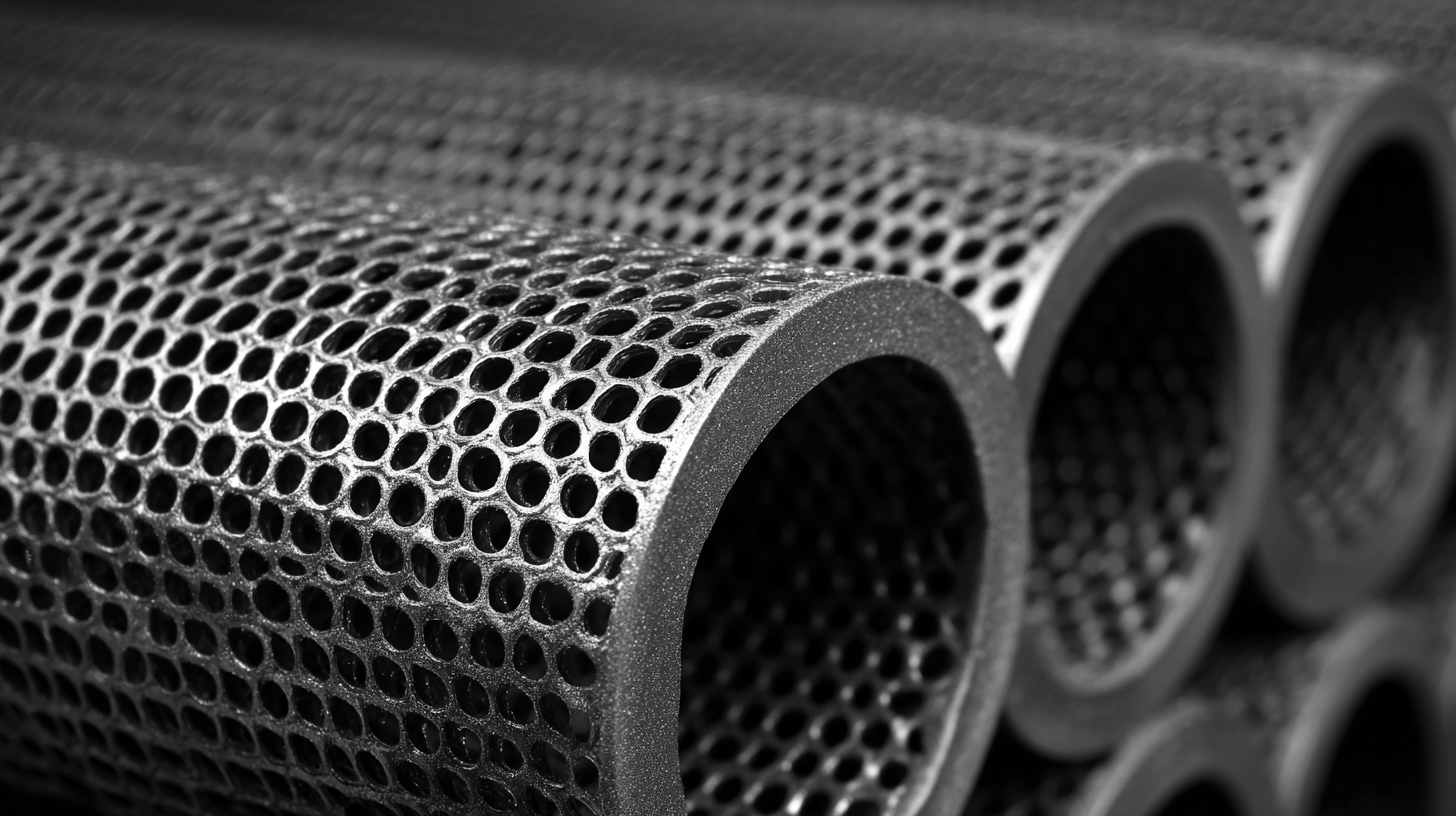

Another important consideration is the mesh opening size. The right opening size can impact both the efficiency of the screening process and the quality of the end product. A larger opening may help in speeding up processes, but can lead to lower precision in separation, while finer meshes provide better filtration but can become clogged more easily.

Tip: Conduct a few trial runs with different mesh sizes to identify which option yields the best balance between productivity and quality for your specific application.

When selecting the right urethane screen mesh for your industrial needs, understanding the specifications such as thickness, micron rating, and durability is critical. The thickness of the mesh determines its strength and the type of material it can handle. Thicker meshes tend to be more durable, but it's essential to balance thickness with flexibility based on your application.

The micron rating indicates the size of particles that can pass through the mesh. A lower micron rating means finer filtration, which is ideal for applications requiring high precision. Conversely, a higher micron rating allows for larger particulates to pass, which may be suitable for less demanding tasks.

**Tips:** When assessing thickness, consider the environment in which the mesh will be used; areas with abrasive materials may benefit from a thicker mesh. Additionally, always review the durability claims from manufacturers—look for evidence of performance in similar conditions to yours. Finally, testing a small sample of the mesh can provide insight into how it performs under real-world conditions.

When selecting urethane screen mesh for industrial applications, evaluating material compatibility is crucial. Understanding the specific process requirements—such as temperature, chemical exposure, and mechanical stresses—will guide you in choosing the right mesh. Urethane offers versatility, but not every type will withstand the unique demands of your operation. Consider the environment where the mesh will be used; for instance, if you're working with abrasive materials, a high-strength urethane mesh may be necessary to prolong its lifespan.

Tip: Always check the manufacturer's datasheet for information on the urethane mesh's compatibility with various chemicals. This ensures that the material won't degrade or lose its functional properties over time. Additionally, if your operations involve varying temperatures, look for meshes designed to resist thermal changes without compromising structural integrity.

Another crucial aspect is the mesh's aperture size, which impacts filtration efficiency and flow rate. The right aperture will enhance performance while preventing unwanted contaminants from passing through. Always align your mesh specifications with your process needs to optimize the efficiency and effectiveness of your operations.

Tip: Conduct a trial with a small batch of mesh to see how it performs under real conditions. This initial testing phase can reveal potential issues before committing to a larger order.

When selecting urethane screen mesh for industrial applications, it's crucial to consider the geometry of the mesh openings, as it significantly impacts screening efficiency. Recent studies have indicated that shapes like triangular "V-shaped" openings can lead to reduced head loss while enhancing hydraulic performance. This innovative design addresses common issues faced by traditional screens, such as clogging and inefficiency. The structure of the screen mesh directly affects how materials are processed and separated, making it essential to choose a shape that aligns with your specific operational goals.

Further advancements in screening technology have highlighted the importance of tailored designs for various materials. For instance, research involving particle-scale models in recycling silicon photovoltaic panels demonstrated that the shape of the screening holes influences the separation efficiency. Similarly, discrete element simulations reveal that incorporating variable rectangular holes can improve both processing capacity and separation accuracy. By assessing these factors and optimizing the mesh opening shapes, industries can achieve significant enhancements in their screening processes, ultimately leading to better performance and reduced operational costs.

When selecting the right urethane screen mesh for your industrial applications, cost-effectiveness should be a critical factor in your decision-making process. According to market forecasts, the global polyurethane market is expected to grow from $127.85 billion in 2024 to $194.62 billion by 2032, with a compound annual growth rate (CAGR) of 5.4%. This growth reflects an increasing adoption of advanced materials, including urethane, which provide superior benefits over traditional options. Urethane screen meshes offer enhanced durability and performance, translating to lower costs in maintenance and replacement over time.

Tips: When transitioning from traditional materials to urethane, consider conducting a life-cycle cost analysis. This will help you understand long-term savings versus initial investments. Additionally, evaluate the specific environmental conditions your mesh will face; urethane's resistance to abrasion and chemicals often makes it a better choice.

Furthermore, as industries increasingly shift toward thermoplastic materials, the thermoplastic pipe market is projected to grow from $4.05 billion in 2024 to $6.14 billion by 2032. This trend underscores the need for materials like urethane, which can endure high performance standards. Embracing these advancements now can provide both immediate benefits and long-term returns on investment.