No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

When it comes to optimizing production processes, the choice of materials plays a crucial role in determining efficiency and quality. One such material that has gained popularity across various industries is fine mesh. This versatile solution not only enhances filtration and separation processes but also offers a range of benefits that can significantly improve operational outcomes. From increased durability to improved precision in application, the advantages of fine mesh make it an indispensable choice for manufacturers and producers. In this blog, we will explore five essential benefits of choosing fine mesh for your production needs, highlighting how it can streamline operations, reduce costs, and ultimately lead to superior product results. Understanding these benefits can provide valuable insights for businesses looking to enhance their production methods and achieve better efficiency in their processes.

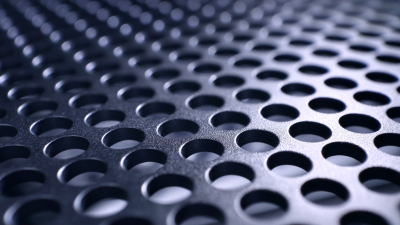

Fine mesh materials have become integral in various production applications, offering unique advantages that enhance efficiency and product quality. Understanding what fine mesh entails is essential for businesses aiming to optimize their manufacturing processes. Typically defined by their small openings that allow finer particles to pass through, fine mesh products are utilized in industries ranging from food processing to pharmaceuticals. Their ability to separate and filter materials with precision makes them indispensable for ensuring product purity and consistency.

One of the primary benefits of fine mesh is its versatility. It can be tailored to suit specific production needs, such as different mesh sizes, materials, and coatings. This adaptability makes fine mesh suitable for a wide range of tasks, including sieving, filtering, and straining. Furthermore, fine mesh is designed to withstand various environmental conditions, enhancing durability and lifespan. By incorporating fine mesh into their operations, businesses can achieve higher output quality, reduced waste, and improved cost-effectiveness, leading to a more streamlined production process.

This bar chart illustrates the essential benefits of using fine mesh materials in production. Each benefit is rated based on its importance and effectiveness in improving production efficiency and quality. The ratings indicate how critical each benefit is perceived in the context of production applications.

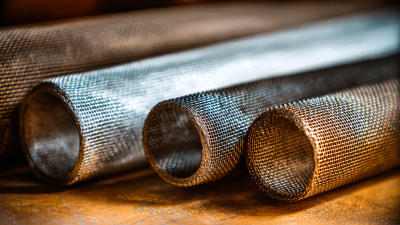

Fine mesh materials are increasingly recognized for their pivotal role in

filtration and separation processes across various industries. One key advantage of fine mesh is its

superior filtration efficiency. According to a study by the

Filtration and Separation Technology Journal, implementing fine mesh screens can

enhance separation efficacy by up to 90%, particularly in

applications involving intricate particle sizes. This level of precision is crucial in industries like

pharmaceuticals and food processing, where product purity is

non-negotiable.

Additionally, fine mesh offers enhanced durability and life span

compared to coarser alternatives. A report from the

International Filtration Society highlights that fine mesh materials,

such as stainless steel or synthetic options, can withstand high-pressure environments and corrosive substances,

thus reducing maintenance costs and downtime. This resilience ensures that organizations can maintain

continuous production without frequent replacements, leading to

increased operational efficiency and reduced overall costs.

The ability of fine mesh to provide consistent, reliable separation further solidifies its position as a

vital component in modern production settings.

In today’s fast-paced manufacturing environment, enhancing production workflows is critical to staying competitive. Fine mesh materials play a pivotal role in improving efficiency by allowing for better material separation and processing. By utilizing fine mesh screens, manufacturers can achieve precise filtering, ensuring that only the desired particles pass through. This not only speeds up the production process but also minimizes waste, leading to more streamlined operations.

Moreover, fine mesh enhances productivity by reducing downtime. Traditional filtration and separation methods often require frequent maintenance and cleaning, interrupting the workflow. In contrast, fine mesh systems are designed to be more resilient and require less frequent intervention. As a result, production teams can focus on their tasks with fewer interruptions, ultimately leading to higher output rates. The lightweight and durable nature of fine mesh materials also means they can be easily integrated into existing setups, making the transition to enhanced efficiency straightforward and cost-effective.

When considering production needs, fine mesh solutions stand out for their cost-effectiveness and potential for long-term savings. A recent report indicates that businesses that adopt fine mesh technologies can reduce waste by up to 20%, leading to significant savings over time. Additionally, fine mesh materials often require less maintenance than traditional systems, which translates into lower operational costs. As industries, from horticulture to pharmaceuticals, evolve, leveraging cost-efficient options becomes increasingly crucial in driving competitive advantages.

Tips: When evaluating fine mesh solutions, it’s important to assess the initial investment versus anticipated savings. Consider performing a cost-benefit analysis to identify potential operational efficiencies. Companies should also keep in mind the evolving technological landscape; utilizing fine mesh in conjunction with advancements in automation can further enhance productivity and minimize expenses.

Adopting fine mesh not only contributes to immediate savings but also aligns with broader trends in achieving economies of scale. According to industry data, companies that invest in efficient production methods can lower per-unit costs significantly as they scale their operations. Integration of fine mesh solutions can thus be a strategic move, ensuring that businesses are well-positioned to meet market demands while maintaining a focus on cost control.

Fine mesh materials are becoming increasingly recognized in various production sectors for their compliance with industry standards. The precision of fine mesh not only ensures high-quality output but also enhances safety protocols across manufacturing processes. By utilizing fine mesh, companies can meet stringent regulations regarding particle size and material quality, ultimately leading to improved product integrity. This compliance benefits both manufacturers and consumers, as it establishes trust and reliability in the products being produced.

In addition to regulatory compliance, the adoption of fine mesh aligns with the emerging trends in sustainable practices within the industry. Innovations in fine mesh technology lead to enhanced performance and resource efficiency, which is crucial in today’s environmentally conscious market. As the focus on sustainability grows, using fine mesh can contribute to minimizing waste and optimizing material usage—key considerations for any production strategy aiming for longevity and minimal environmental impact. By choosing fine mesh, companies can not only fulfill compliance obligations but also position themselves as leaders in the shift towards sustainable production methodologies.