No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the realm of filtration and separation technologies, the significance of a "Fine Mesh Screen" cannot be overstated. These specialized screens, characterized by their closely spaced openings, play a crucial role across diverse industries, ranging from food processing to water treatment. According to Dr. Susan Leverage, a noted expert in filtration systems, "Fine Mesh Screens are essential for achieving high levels of purity and efficiency in any filtration process." This statement underscores the integral function of fine mesh screens in ensuring top-notch performance while minimizing impurities.

As industries increasingly prioritize quality and efficiency, understanding the various applications and benefits of fine mesh screens becomes imperative. These screens not only enhance the quality of products but also optimize operational workflows, demonstrating their versatility. With applications spanning from industrial manufacturing to specialty applications, fine mesh screens continue to evolve, catering to the ever-changing demands of modern technology and industry standards.

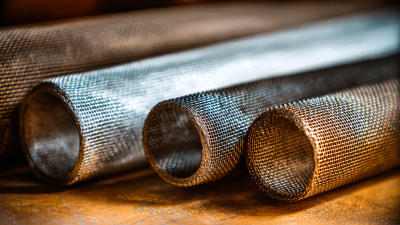

A fine mesh screen is defined as a filtration medium characterized by its small openings, typically less than 1 millimeter in size. These screens are crafted from various materials, including stainless steel, nylon, and polyester, which provide durability and resistance to corrosion. The mesh size can range widely, with finer options being able to filter out particles as small as 15 microns. According to the Global Filtration Market Report, the demand for filtration products, including fine mesh screens, has seen a significant rise, projected to grow at a compound annual growth rate (CAGR) of 5.6% through 2027. This increase is driven by strict regulatory standards in industries such as food processing, pharmaceuticals, and wastewater treatment, which necessitate high levels of purity and safety.

Fine mesh screens are utilized across multiple applications due to their effectiveness in separating materials. In the food and beverage sector, they play a crucial role in filtering ingredients and ensuring product consistency. For instance, they are commonly used in brewing to separate grain from wort. In the pharmaceutical industry, fine mesh screens are essential for ensuring that drugs meet required particle size specifications, thereby improving bioavailability and efficacy. Furthermore, in environmental applications, they are employed in the treatment of wastewater, efficiently capturing solids and particulate matter to enhance water quality. The versatility and precision of fine mesh screens make them indispensable tools in numerous industries, highlighting their significance in modern manufacturing and quality control processes.

Fine mesh screens are utilized across a multitude of industries, serving as essential components in filtration, separation, and screening processes. The manufacturing of these screens involves various materials, each selected for specific applications based on their properties. The most common materials used in fine mesh screen production include stainless steel, nylon, polyester, and aluminum.

Stainless steel is favored for its durability and resistance to corrosion, making it ideal for applications in food processing and pharmaceuticals. According to a report by MarketsandMarkets, the stainless steel mesh market is projected to grow at a CAGR of 4.2% from 2021 to 2026, highlighting its increasing demand.

Nylon and polyester mesh screens are often employed in industries such as electronics and textiles due to their excellent chemical resistance and flexibility. These synthetic materials are particularly useful for applications requiring lightweight and high-performance filtration. The global synthetic mesh market is expected to witness significant growth, with a focus on the development of advanced materials capable of withstanding high temperatures and abrasive environments.

Tips: When selecting a fine mesh screen, consider the specific requirements of your application, including the type of particles to be filtered and the operating conditions. Regular maintenance is crucial to ensure optimal performance and longevity of the mesh screen, regardless of the material chosen. Always consult industry standards and guidelines to ensure compliance and efficacy in your applications.

Fine mesh screens are essential tools in various filtration processes across numerous industries. Their design typically consists of a tightly woven mesh material that effectively captures small particles while allowing liquids or gases to pass through. In the food and beverage industry, for instance, fine mesh screens are employed to filter out impurities from liquids, ensuring that only clean and safe products reach consumers. This application not only enhances product quality but also contributes to compliance with stringent health regulations.

In industrial settings, fine mesh screens play a crucial role in maintaining operational efficiency by preventing contaminants from entering machinery and processes. They are commonly used in processes such as water treatment, where they filter out sediments and other particulates from water sources. Similarly, in the pharmaceutical sector, these screens help to ensure the purity of active ingredients by removing unwanted particles during the manufacturing process. The versatility of fine mesh screens makes them invaluable in maintaining the integrity of various products while improving the overall reliability of production systems.

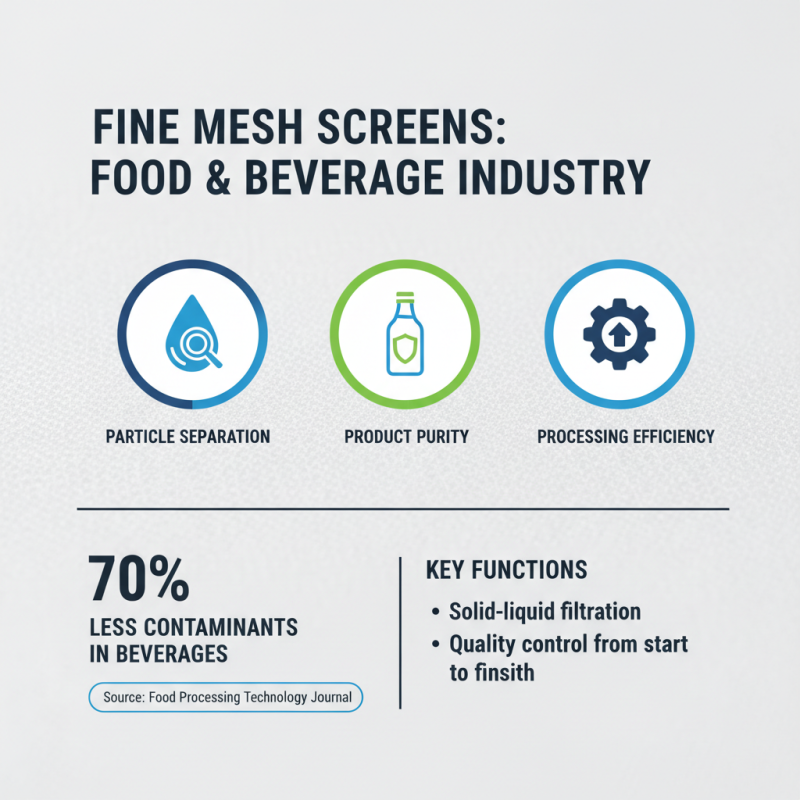

Fine mesh screens are pivotal in the food and beverage industries, serving various essential functions that enhance product quality and processing efficiency. A fine mesh screen, typically characterized by its closely woven fabric and small aperture size, effectively separates solid particles from liquids during various stages of production, from initial processing to final product filtration. For instance, according to a report by the Food Processing Technology journal, up to 70% of contaminants in beverages can be minimized through the use of fine mesh filtration, ensuring that the final products are not only safe but also visually appealing to consumers.

In the brewing industry, fine mesh screens play a crucial role in the filtration of wort and beer, where achieving clarity and eliminating unwanted particles is vital for quality assurance. Research from the Beverage Industry Association highlights that breweries utilizing advanced filtration techniques, including fine mesh screens, report a 15% reduction in production waste, optimizing both operational efficiency and economic viability. Similarly, in the dairy sector, these screens assist in the separation of cream and whey, contributing to improved texture and flavor in products like yogurt and cheese. The implementation of fine mesh screens in these processes not only enhances product quality but also aligns with industry standards for food safety, reinforcing their importance in the ongoing pursuit of excellence within the food and beverage sectors.

Fine mesh screens have become essential tools in various industrial applications due to their remarkable versatility and efficiency. These screens, characterized by their tightly woven fabric and small openings, are widely utilized in filtering and separating materials across industries. In manufacturing settings, fine mesh screens can be employed to sift raw materials, ensuring that only particles of the desired size proceed through the production line. This precise separation ultimately improves product quality and reduces waste, contributing to a more streamlined operation.

In addition to filtering, fine mesh screens also play a crucial role in areas such as food processing and pharmaceuticals. In these industries, hygiene and safety are paramount, and fine mesh screens help maintain these standards by preventing contaminants from entering the final products. For instance, in food packaging, they are used to create barrier systems that protect products from external elements while allowing necessary airflow. Moreover, in the pharmaceutical sector, fine mesh screens are vital for the accurate formulation of drugs, ensuring that active ingredients are consistently distributed without unwanted particles. Their innovative applications continue to evolve as industries seek more efficient ways to maintain quality and safety standards through advanced separation techniques.

| Application | Material | Mesh Size (Microns) | Benefits |

|---|---|---|---|

| Filtration in Water Treatment | Stainless Steel | 50 | Durability and rust resistance |

| Sieving in Food Processing | Polyester | 100 | Chemical resistance and easy cleaning |

| Air Filtration in HVAC Systems | Aluminum | 30 | Lightweight and effective for dust collection |

| Industrial Cleaning | Nylon | 200 | Flexibility and resistance to abrasion |

| Pharmaceutical Manufacturing | Wire Mesh | 10 | High precision and non-reactive |