No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the ever-evolving landscape of industrial filtration and material processing, the introduction of innovative technologies stands at the forefront of enhancing operational efficiency and sustainability. One such advancement is the MDI PU tension screen, a cutting-edge solution designed to meet the demanding requirements of various industries. As global procurement strategies continue to adapt to changing market dynamics, understanding the transformative potential of MDI PU tension screens is essential.

This ultimate guide will explore the future of high-performance tension screens, focusing on the latest innovations and best practices that can help businesses streamline their procurement processes, improve performance, and stay competitive in a rapidly advancing marketplace.

Join us as we delve into the significant developments shaping the future of MDI PU tension screens and their impact on global supply chains.

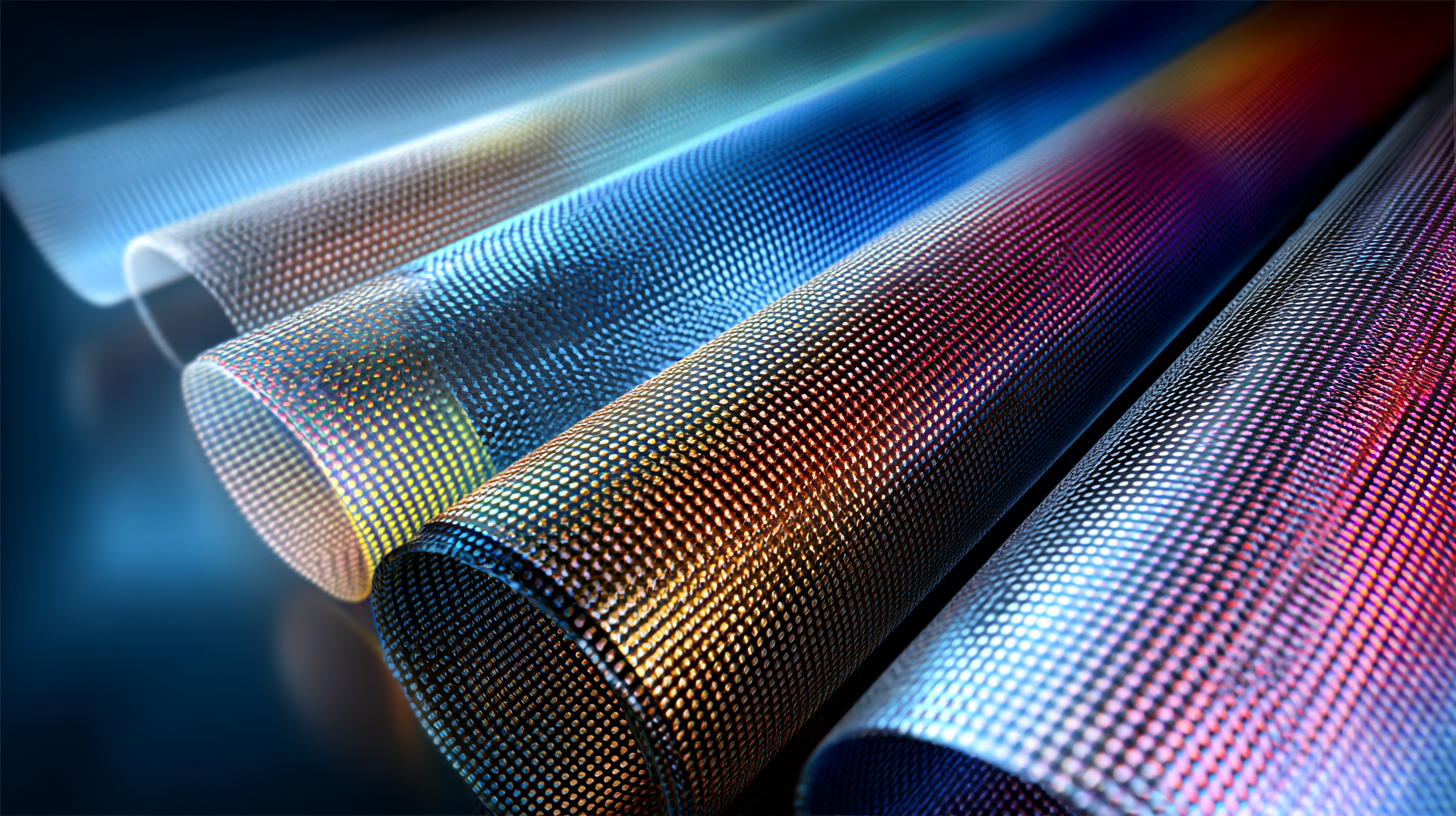

The evolution of MDI PU tension screens has been marked by significant technological advancements that cater to the demands of high-performance applications across various industries. These screens, essential for efficient material processing, have seen improvements in durability, weight reduction, and operational efficiency. Recent innovations have opened up new avenues for enhancing user experience and maximizing output, particularly in challenging environments.

One of the most exciting developments in this realm is the introduction of advanced polyurethane materials designed to outperform traditional options. With extensive testing confirming their efficacy, the new polyurethane screen media panels are set to transform the landscape of high-performance screening. These innovations promise enhanced wear resistance and improved screening capabilities, making them suitable for an array of applications, from mining to recycling. As these materials become commercially available, they pave the way for global procurement strategies that seek to leverage cutting-edge technology for better performance and sustainability in operations.

The polyurethane (PU) market, particularly in high-performance applications like MDI PU tension screens, is witnessing transformative innovations that promise to redefine global procurement strategies. According to industry analysts, the PU sole footwear market alone is projected to showcase a compound annual growth rate (CAGR) exceeding 7% from 2025 to 2032. This growth is significantly driven by advancements in material properties and manufacturing techniques, which enhance durability and performance in a variety of applications, from automotive components to consumer goods.

China's role in the chemicals industry is pivotal as it continues to lead in the production of basic chemicals. However, the country has been criticized for lagging in the innovation spectrum. While basic chemical production is robust, there is a pressing need to invest in R&D to foster innovative solutions that align with global sustainability goals. This gap presents a significant opportunity for companies looking to leverage cutting-edge technologies, particularly in green chemistry, to meet the growing demand for sustainable materials and processes. Engaging with industry leaders and innovators is crucial to drive forward-looking strategies that capitalize on these trends.

Sustainability is a critical focal point in the global procurement of MDI PU tension screens, reflecting a broader trend toward environmentally conscious manufacturing and supply chain practices. Manufacturers are increasingly adopting sustainable materials and processes to produce these high-performance screens, which are essential in various industries such as oil and gas, mineral processing, and water treatment. The shift towards sustainability not only reduces environmental impact but also appeals to the growing number of eco-conscious consumers and organizations prioritizing green procurement.

Sustainability is a critical focal point in the global procurement of MDI PU tension screens, reflecting a broader trend toward environmentally conscious manufacturing and supply chain practices. Manufacturers are increasingly adopting sustainable materials and processes to produce these high-performance screens, which are essential in various industries such as oil and gas, mineral processing, and water treatment. The shift towards sustainability not only reduces environmental impact but also appeals to the growing number of eco-conscious consumers and organizations prioritizing green procurement.

In addition to using eco-friendly materials, companies are exploring innovative recycling methods for MDI PU tension screens. End-of-life product management is becoming a significant concern, prompting suppliers to develop take-back programs that ensure materials are responsibly recycled or repurposed. Moreover, collaboration across the supply chain is fostering transparency and ethical sourcing, enabling businesses to track the environmental footprint of their products from production to disposal. This commitment to sustainability within global procurement not only bolsters a company’s reputation but also contributes to a more sustainable future for all stakeholders involved.

The global procurement of high-performance MDI (Methylene Diphenyl Diisocyanate) PU (Polyurethane) materials presents a unique set of challenges that manufacturers must navigate. Fluctuating raw material prices, supply chain disruptions, and stringent regulatory requirements can complicate the sourcing process. As demand for eco-friendly and durable materials continues to rise, procurement teams are pressured to ensure that their suppliers not only meet quality standards but also adhere to sustainability practices.

To tackle these challenges, innovative solutions are emerging within the industry. Strategic partnerships with reliable suppliers can enhance supply chain stability, allowing for better pricing and consistent material quality. Additionally, investing in advanced technologies such as predictive analytics can provide valuable insights into market trends and inventory management, helping procurement teams make informed decisions. Emphasizing collaborative relationships with suppliers can also foster transparency and agility, ensuring that companies remain competitive in an evolving landscape of high-performance materials.

| Dimension | Current Trends | Challenges | Solutions | Future Innovations |

|---|---|---|---|---|

| Material Quality | Increased focus on sustainability | Variability in material properties | Standardized testing protocols | Biodegradable materials |

| Supply Chain | Global sourcing strategies | Disruptions due to geopolitical issues | Diversifying supplier base | Blockchain for traceability |

| Cost Management | Focus on cost reduction | Fluctuating raw material prices | Long-term contracts with suppliers | Development of alternative sources |

| Technology Advancement | Adoption of automation | Integrating new technologies | Training and skill development | AI-driven material forecasting |

In the dynamic realm of industrial manufacturing, implementing innovative MDI PU tension screens is pivotal for enhancing performance and efficiency. Industries are increasingly adopting these advanced materials, which offer superior durability and flexibility, making them ideal for demanding applications. To harness the full potential of these technologies, companies must focus on best practices that facilitate seamless integration into existing workflows. This includes comprehensive training for personnel and investing in research to understand the unique properties of MDI PU materials.

Moreover, successful implementation entails a commitment to sustainability and reducing environmental impact. Companies should prioritize sourcing materials responsibly and adopting eco-friendly practices throughout the procurement process. By fostering collaboration between suppliers and manufacturers, the potential of MDI PU tension screens can be maximized, paving the way for innovation and improved productivity across various sectors. As organizations navigate these advancements, the emphasis on strategic, forward-thinking approaches will ensure they remain competitive in an ever-evolving global market.