No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

When selecting the right Fine Mesh Screen for various applications, understanding the alternatives available is crucial. According to industry reports, the demand for fine mesh screening solutions has surged by nearly 25% in the past five years, driven by innovations in agricultural, industrial, and environmental sectors. Fine mesh screens are versatile tools, essential for filtration, separation, and containment processes. The market is now flooded with options ranging from metal to synthetic materials, each boasting unique properties catered to specific needs. As businesses and DIY enthusiasts alike strive for efficiency and precision, choosing the best alternative requires careful consideration of factors such as material durability, pore size, and application suitability. This guide will explore the various alternatives to fine mesh screens, helping you make an informed choice that meets your specific needs and enhances your overall project efficacy.

When selecting a fine mesh screen, several key features should be at the forefront of your decision-making process. First and foremost, mesh size is crucial as it determines the screen's filtration capability. According to a report by MarketsandMarkets, the global filtration market is projected to grow from $94 billion in 2020 to $140 billion by 2025, highlighting the increasing demand for effective filtration solutions. Understanding mesh size—measured in microns—is essential, as it dictates which particles can be filtered out, ranging from large debris to microscopic pollutants.

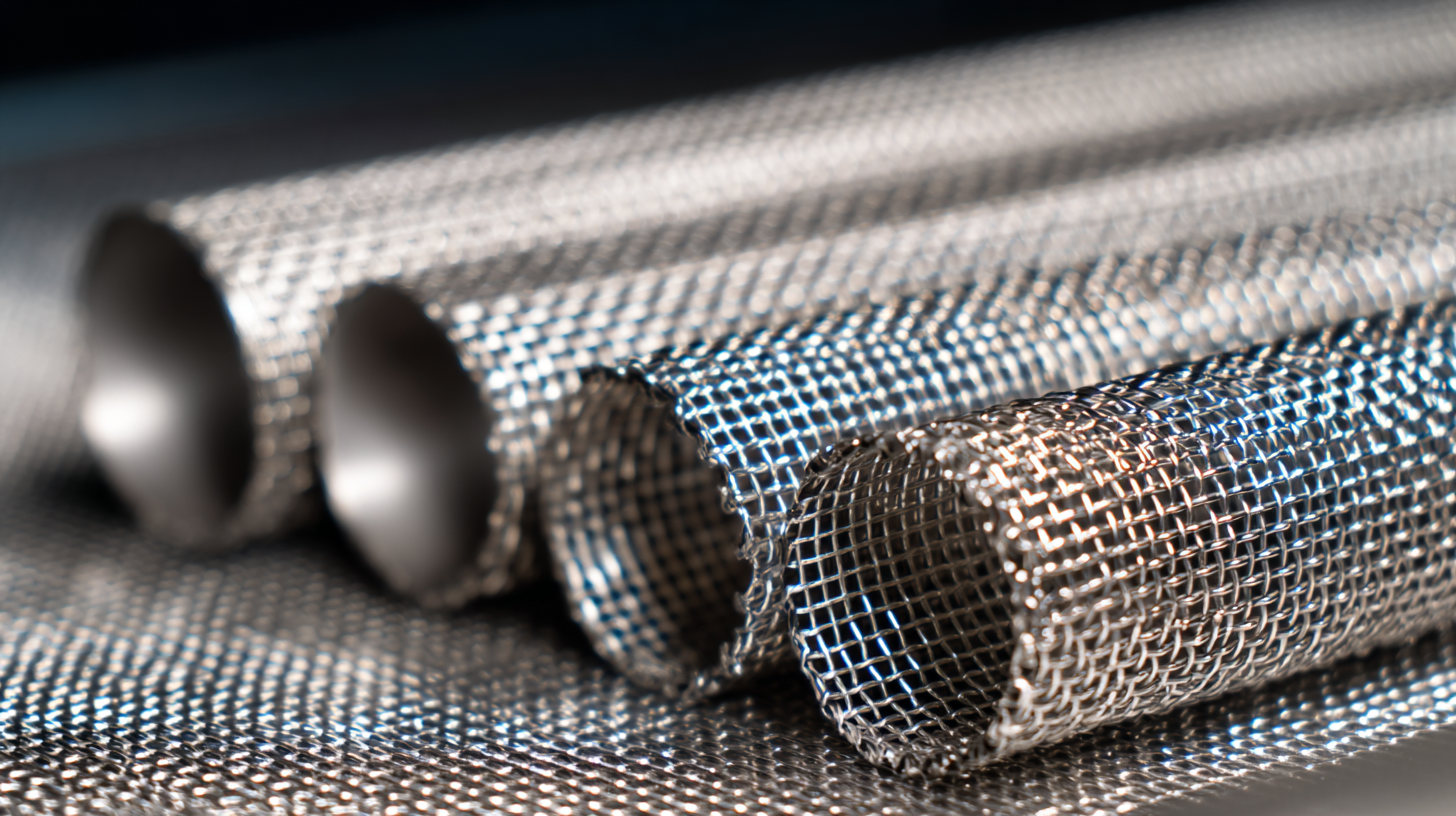

Another critical factor is the material of the mesh screen. Options include stainless steel, nylon, and polyester, each with unique properties suited for different applications. A study published in the Journal of Industrial Filtration indicates that stainless steel screens offer superior durability and resistance to corrosion, making them ideal for heavy-duty operations. Conversely, nylon mesh is often favored for its lighter weight and flexibility, making it better suited for applications requiring ease of handling. Ultimately, considering these features will ensure you choose a fine mesh screen that meets your specific needs efficiently.

When it comes to selecting the right fine mesh screen, understanding the offerings from top brands can significantly impact your decision. Brands like McMaster-Carr, AmazonBasics, and A.M.A products have emerged as leaders in the market, known for their quality and range of options. McMaster-Carr, for instance, provides robust industrial-grade screens that cater to professionals, featuring varying mesh sizes that ensure both durability and efficiency. Their comprehensive selection allows users to filter applications based on material, size, and use case, making it easier to find the perfect fit.

On the other hand, AmazonBasics offers a more budget-friendly approach without compromising on quality. These screens are ideal for casual users or DIY enthusiasts looking for effective yet affordable solutions. A.M.A products, while not as widely recognized, have gained a loyal following for their innovative designs and emphasis on eco-friendly materials. Each brand offers unique strengths, from superior engineering to cost-effective options, enabling consumers to choose the fine mesh screen that best suits their specific needs and preferences.

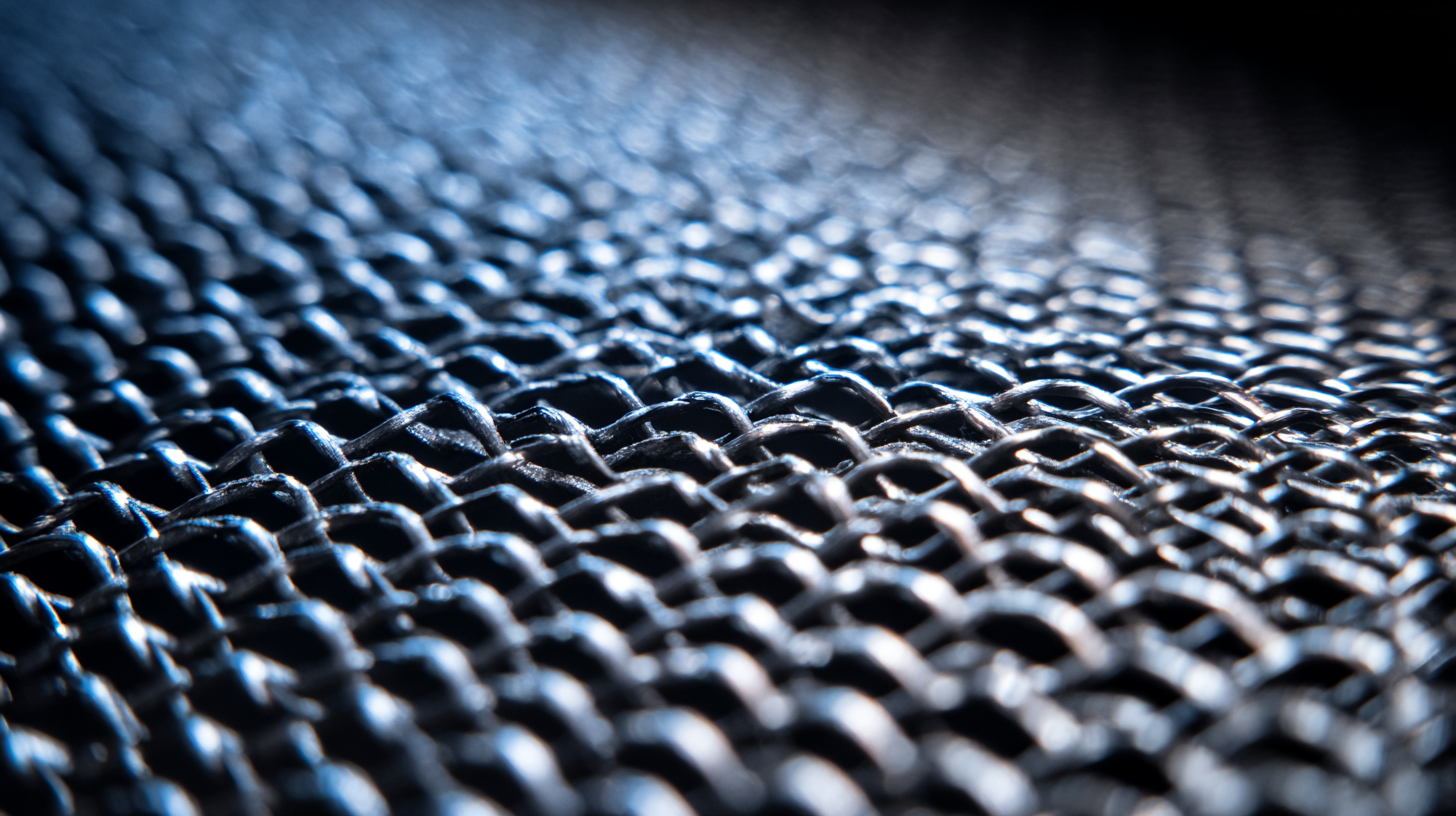

When it comes to selecting the right fine mesh screen, understanding the material differences is crucial. Fine mesh screens can be made from various materials such as nylon, stainless steel, and polypropylene, each catering to different applications. Nylon screens are lightweight and ideal for dry applications; they offer excellent filtration but can degrade when exposed to UV light. On the other hand, stainless steel screens are robust and durable, making them perfect for both high-temperature and corrosive environments. They are particularly suitable for industrial uses where longevity is essential.

Tips: Always consider the intended environment for your screen. If you're using the screen outdoors, stainless steel or UV-stabilized nylon may be your best options to resist weathering. For home brewing or food applications, choose materials that are safe and easy to clean, such as food-grade stainless steel. Additionally, think about the mesh size; finer meshes will filter smaller particles but may clog more easily, requiring frequent maintenance.

Another critical factor is the screen's weave pattern. Some materials have a tighter weave that offers increased filtration efficiency, while others may prioritize airflow. If air circulation is vital, look for screens designed with an open weave that strikes a balance between filtration and airflow. Ensuring you choose the right material and weave will guarantee that the fine mesh screen meets your specific requirements effectively.

| Material Type | Mesh Size (Microns) | Durability | Best Use Case | Cost (per sq. ft.) |

|---|---|---|---|---|

| Stainless Steel | 20-100 | High | Industrial uses, filtration | $3.50 |

| Aluminum | 25-150 | Medium | Home use, gardening | $2.50 |

| Polyester | 50-300 | Medium | Craft projects, fine filtration | $1.50 |

| Silk | 10-200 | Low | Art and crafts, light filtration | $4.00 |

| Nylon | 30-400 | Medium | Screen printing, general use | $2.00 |

When selecting a fine mesh screen, conducting a thorough cost-benefit analysis is crucial. Fine mesh screens come in various materials and designs, each offering unique advantages that can impact your choice significantly. For instance, stainless steel screens are durable and rust-resistant, making them a cost-effective option for long-term use, while nylon mesh screens might be more affordable upfront but may require more frequent replacements. Understanding the lifespan and maintenance requirements of different materials can help you calculate long-term savings versus initial investment.

Additionally, consider the specific applications and the value each type of screen brings to your project. Whether you're filtering water, separating particles in a laboratory, or preventing pests in gardening, the right fine mesh screen enhances efficiency and effectiveness. Analyzing factors such as flow rate, mesh size, and compatibility with existing systems will inform better purchasing decisions. By weighing these considerations, you can identify options that not only fit your budget but also provide substantial practical benefits, ensuring that your investment delivers real value over time.

Fine mesh screens have become essential tools across various industries, serving specific applications that enhance productivity and efficiency. In the food processing sector, for example, fine mesh screens help in separating solids from liquids, reducing waste and ensuring purity. According to the 2022 report by the Food Processing Industry Association, approximately 40% of companies have adopted advanced filtration systems, including fine mesh screens, to comply with stringent safety regulations and improve product quality.

In the fields of pharmaceuticals and water treatment, fine mesh screens are critical for ensuring the consistency and reliability of products. Studies by the International Water Association indicate that incorporating fine mesh filtration can lead to a 30% increase in clean water recovery rates. Such screens effectively trap contaminants and particulate matter, promoting better overall system performance. Furthermore, with the growing emphasis on sustainability, the use of fine mesh screens enables industries to recycle and recover resources more efficiently, solidifying their position as a vital component in modern processing solutions.