No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

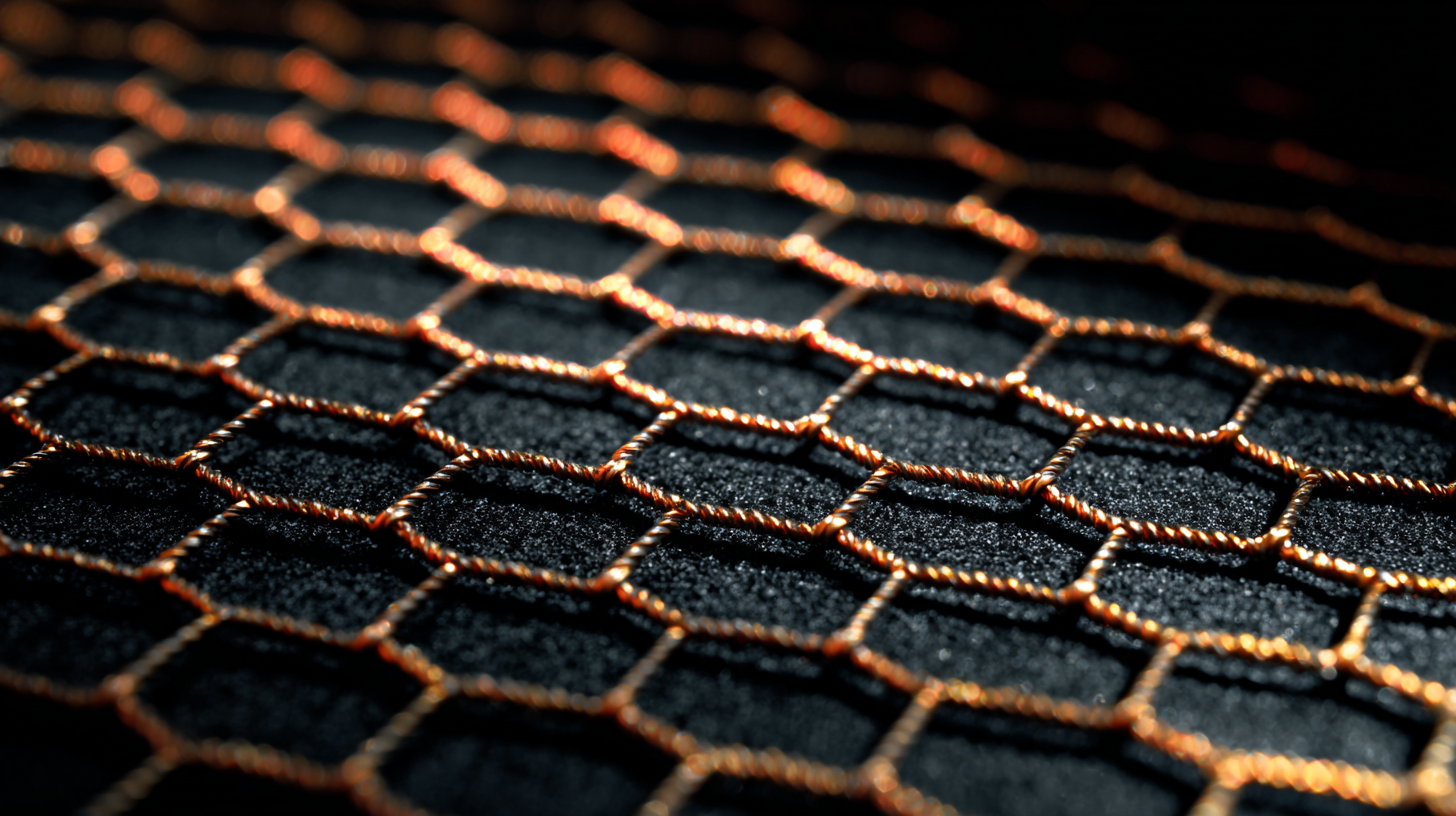

In today's fast-paced industrial landscape, the selection of the right Fine Mesh Screen is critical to optimizing efficiency and ensuring product quality across various applications. According to a recent report by MarketsandMarkets, the global market for mesh filtration is projected to reach USD 3.5 billion by 2027, driven by increased demand in the pharmaceutical, food and beverage, and chemical industries. As businesses strive to enhance operational performance and comply with stringent regulatory requirements, fine mesh screens have emerged as essential tools for filtration, separation, and processing. This ultimate guide will help you navigate through the myriad options available, ensuring that you choose a fine mesh screen that aligns perfectly with your specific needs, whether it's for general use or specialized applications in advanced settings.

Fine mesh screens play a crucial role in a wide array of applications, from home gardening to industrial filtration. Their ability to filter out particles without obstructing airflow makes them invaluable in both commercial and residential settings. For instance, in agriculture, fine mesh screens prevent insects from damaging crops while allowing sunlight and rain to nourish them. Similarly, in water treatment facilities, fine mesh screens are instrumental in filtering out contaminants, ensuring clean water supply.

When selecting a fine mesh screen, consider the specific needs of your application. The mesh size—measured in microns—will determine what particles can be filtered out. For gardening, a mesh size of around 50-100 microns is usually effective against pests, while in industrial settings, a finer mesh may be necessary to trap smaller particulates.

Tip: Always assess the environmental conditions where the screen will be used. UV-resistant materials are essential for outdoor applications to prolong the lifespan of the screen. Additionally, think about the ease of cleaning; removable and washable screens can save you time and effort in maintenance.

When selecting a fine mesh screen, several key factors demand careful consideration to ensure optimal performance in your specific application. First and foremost, the mesh material plays a crucial role in durability and functionality. According to a report by the International Society of Automation, stainless steel screens are preferred in industries where corrosive materials are handled, due to their remarkable resistance to rust and wear. In contrast, nylon screens are often utilized in food processing for their flexibility and ease of cleaning.

Another critical aspect is the mesh size, which is essential for achieving the desired filtration efficiency. Studies indicate that screens with openings between 100 to 400 microns are commonly effective for mechanical separation in various industrial processes. The micron rating indicates the size of particles that can pass through, influencing everything from dust collection to liquid filtration. A rigorous analysis of your operational requirements, such as flow rate and material types, will help you select the appropriate mesh size, ensuring both effectiveness and longevity of the screen in its operational environment.

When it comes to selecting a fine mesh screen, understanding the various types available on the market is essential to making an informed choice. Fine mesh screens can be categorized into several types, including nylon, polyester, and stainless steel mesh, each serving specific applications and industries. According to a report by Grand View Research, the fine mesh screen market is projected to reach $3.4 billion by 2025, driven by the growing demand across sectors such as pharmaceuticals, food and beverage, and water treatment.

Nylon screens are popular due to their flexibility and resistance to corrosion, making them ideal for delicate applications like filtering juices and beverages. In contrast, polyester mesh offers excellent durability and is often used in industrial applications where chemical resistance is vital. Stainless steel screens are renowned for their strength and longevity, commonly utilized in commercial settings where high temperatures and pressures are present. As different industries continue to prioritize efficiency and safety, the selection of the appropriate fine mesh screen becomes a critical factor in operational success. Understanding these types not only aids in meeting specific requirements but also ensures compliance with industry standards.

Fine mesh screens are increasingly gaining popularity in various industries due to their efficiency in filtration and separation processes. Research indicates that employing fine mesh screens can improve the filtration accuracy by up to 95%, significantly higher than traditional filtration methods. This enhanced performance is essential in sectors such as food processing, pharmaceuticals, and wastewater treatment, where the purity of the end product directly affects quality and safety.

When selecting a fine mesh screen, consider the specific requirements of your application. Mesh sizes vary considerably, with some screens having openings as small as 5 microns, which is ideal for applications needing precision, such as creating clear beverages or separating fine particles in chemicals. To ensure optimal filtration, always evaluate the material compatibility of the screen with the substances being processed.

**Tips:**

1. Perform a thorough analysis of the particulate size chart to choose the right mesh opening for your needs.

2. Regularly inspect and clean your fine mesh screens to maintain their effectiveness and prolong their lifespan.

3. Consider investing in screens made from corrosion-resistant materials if you’re working with harsh chemicals.

| Screen Type | Mesh Size (Microns) | Material | Applications | Advantages |

|---|---|---|---|---|

| Stainless Steel | 100 | Stainless Steel | Liquid Filtration, Food Processing | Corrosion Resistant, High Strength |

| Polyester | 200 | Polyester Fiber | Chemical Filtration, Textile Industry | Low Cost, Lightweight |

| Nylon | 50 | Nylon | Water Filtration, Oil Filtering | High Flexibility, Easy to Clean |

| Fiberglass | 5 | Fiberglass | Dust and Particle Filtration | High Filtration Efficiency, Temperature Resistant |

| Wire Mesh | 300 | Wire | Mining, Water Treatment | Durable, Customizable |

When it comes to maintaining a fine mesh screen, regular cleaning can significantly prolong its lifespan. According to a report by the International Journal of Industrial Design, routine maintenance can increase the efficiency of screening applications by up to 35%. This efficiency gain not only results from removing debris and contaminants but also from preserving the integrity of the mesh, which can suffer from neglect.

A simple weekly cleaning routine is advisable, involving a gentle wash with soapy water and a soft brush to avoid damaging the fine structure of the mesh.

A simple weekly cleaning routine is advisable, involving a gentle wash with soapy water and a soft brush to avoid damaging the fine structure of the mesh.

Additionally, proper storage when the screen is not in use is crucial for longevity. A study published by the Filtration Society highlighted that correctly storing fine mesh screens can decrease wear and tear by as much as 25%. It is recommended to roll or fold screens loosely rather than stacking them, which can cause undue stress on the mesh material. By adopting these maintenance practices, users can ensure their fine mesh screens remain effective and durable, leading to better performance in their respective applications.