No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the quest for superior performance in industrial screening applications, the reliance on traditional Urethane Screen Mesh has become increasingly scrutinized. According to a recent industry report by MarketsandMarkets, the global screen mesh market is projected to grow at a CAGR of 6.4% from 2021 to 2026, primarily driven by the need for enhanced durability and efficiency in diverse sectors, including mining and construction. With Urethane Screen Mesh being particularly favored for its wear resistance and flexibility, it nevertheless presents limitations in temperature tolerance and potential environmental impacts. This blog will explore innovative alternatives that not only match but potentially surpass the performance of Urethane Screen Mesh, paving the way for more sustainable and efficient screening solutions tailored to meet the evolving demands of the industry.

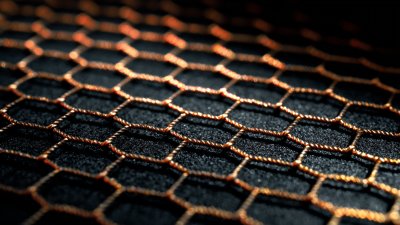

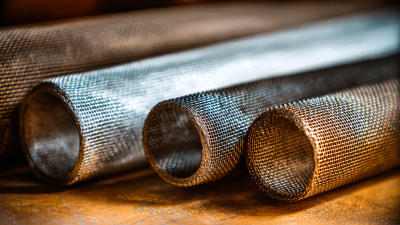

The exploration of innovative materials in screening applications has opened up new paradigms in industrial efficiency, particularly as alternatives to traditional urethane mesh. Recent industry reports indicate that the global polyurethane screen market is projected to experience substantial growth, reaching a significant size by 2033, driven by applications in sectors such as mining and mineral processing. As companies seek high-performance solutions, materials like wire mesh are being reengineered as composite meshes, effectively combining the benefits of flexibility and robustness. This trend highlights the industry's push towards more durable and versatile screening solutions.

In a parallel development, advancements in composite materials, particularly glass fiber reinforced polyurethane composites, exhibit exceptional durability and mechanical stiffness. These properties are crucial for applications that demand high-load-bearing capacities and resistance to environmental wear. Furthermore, the introduction of new polyurethane variants designed for enhanced screen durability promises to extend the lifespan of screening media, thereby optimizing production processes. The integration of these innovative materials not only improves efficiency but also contributes to a more sustainable operational framework in various industries.

As industries strive for higher efficiency and performance, the demand for innovative materials is on the rise. Urethane screen mesh has long been a standard in many applications, but emerging alternatives are proving to offer enhanced benefits. Options like woven wire mesh, polymeric mesh, and even composite materials present not only increased durability but also improved screening capabilities. These alternatives often perform better under extreme conditions, providing longer service life and reducing the need for frequent replacements.

In sectors such as mining, agriculture, and waste management, the performance advantages of these alternative mesh options are particularly pronounced. For instance, woven wire mesh can withstand harsher environments and heavy loads, making it ideal for rigorous screening processes. On the other hand, polymeric meshes are lighter and resistant to corrosion, thereby enhancing efficiency in applications where weight and chemical exposure are concerns. By exploring these innovative materials, industries can optimize their operations, reduce downtime, and ultimately achieve greater sustainability.

| Mesh Type | Material | Application | Performance Advantage | Cost Efficiency |

|---|---|---|---|---|

| Polyester Mesh | Polyester Fibers | Mining, Mineral Processing | High abrasion resistance | Moderate |

| Stainless Steel Mesh | Stainless Steel | Food Processing, Pharmaceuticals | Corrosion resistant, durable | High |

| Nylon Mesh | Nylon | Water Filtration | Excellent flexibility and strength | Low |

| Polypropylene Mesh | Polypropylene | Chemical Filtration | Ultra-lightweight, chemical resistant | Low |

| Fiberglass Mesh | Fiberglass | Construction, Insulation | High tensile strength, fire resistant | Moderate |

The demand for cost-effective and high-performance screening solutions has led to a surge in the exploration of non-urethane alternatives. A comparative analysis highlighted in the recent report by the International Screening Association (ISA) shows that non-urethane screening materials such as polyester and stainless steel offer remarkable durability and efficiency at a lower total cost of ownership. For instance, polyester screen meshes can last up to 25% longer than traditional urethane options, effectively reducing replacement frequency and associated labor costs.

Moreover, the analysis reveals that non-urethane options can outperform urethane meshes in specific applications, such as mineral processing and aggregate separation. According to findings published in the Journal of Materials Science, while the initial purchase price of urethane may be lower, the long-term savings from reduced maintenance and downtime make alternatives like woven wire screens a more economically viable choice. With the global screening media market projected to reach $3 billion by 2025, the shift towards these innovative non-urethane materials is not just a trend, but a strategic move towards enhancing operational efficiency and cost savings in the industry.

When it comes to screening applications, urethane screen mesh has long been the go-to choice for its durability and performance. However, emerging alternatives are challenging this status quo by providing comparable, if not superior, longevity. Materials like stainless steel, polycarbonate, and advanced composites are proving to be robust options. These alternatives often exhibit greater resistance to wear and tear, temperature fluctuations, and chemical exposure, making them ideal for a diverse range of industrial applications.

**Tip:** When considering an alternative to urethane, assess the specific demands of your application. Look for materials that promise high tensile strength and impact resistance to ensure they can withstand the rigors of your operational environment.

Moreover, some alternatives offer enhanced flexibility and lighter weight without sacrificing strength. This shift not only improves the usability of the screening setup but also reduces energy consumption in equipment. For industries that require frequent adaptation or quick changes in operations, these innovations provide the versatility needed to stay competitive.

**Tip:** Conduct a thorough analysis of the lifecycle of each material option. Consider factors such as installation ease, maintenance requirements, and overall cost-effectiveness over time to make an informed decision that aligns with your budget and longevity goals.

The exploration of sustainable choices in screen mesh technology is increasingly critical as industries seek to minimize their environmental footprint. One of the promising alternatives to traditional urethane screen mesh lies in the adoption of innovative materials that reduce waste and improve resource efficiency. For example, the integration of hybrid sensor technologies in environmental monitoring highlights how materials can be optimized for sustainability, allowing for better tracking of ecological impacts associated with resource extraction.

Moreover, the application of life cycle assessment approaches in industrial settings reveals the importance of selecting materials that not only meet performance standards but also enhance environmental sustainability. By comparing materials like glass fiber-reinforced polymers and traditional options, industries can make informed decisions that contribute to both structural integrity and ecological responsibility. As awareness grows regarding the environmental impact of production processes, the shift towards sustainable screen mesh alternatives is gaining momentum, paving the way for enhanced performance without compromising our planet.