No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

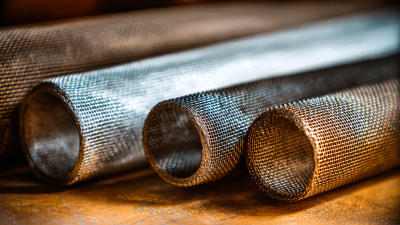

In today’s rapidly evolving industrial landscape, the versatility and functionality of fine mesh metals are paving the way for innovative applications across various sectors. Fine mesh metals, characterized by their intricate designs and exceptional properties, are not just enhancing product performance but also driving efficiency and sustainability. From the aerospace industry, where lightweight materials are crucial, to the food processing sector, where hygiene and filtration are paramount, these materials are proving indispensable.

This blog will explore creative uses of fine mesh metals, offering insights and practical tips on how different industries can leverage these advanced materials to meet their unique challenges. Join us as we delve into the transformative role fine mesh metals play in modern applications, highlighting their potential to reshape the future of manufacturing and engineering.

Fine mesh metals are becoming increasingly crucial in modern manufacturing processes, offering a wide array of benefits across various industries. Their unique properties, such as high strength-to-weight ratios and excellent filtration capabilities, make them ideal for applications ranging from aerospace to pharmaceuticals. By utilizing fine mesh metals, manufacturers can achieve greater precision and improve the quality of end products, leading to enhanced operational efficiency.

Tip: When selecting fine mesh metals for your projects, consider factors such as mesh size, material composition, and environmental conditions. This ensures optimal performance and longevity of the materials.

Additionally, the adaptability of fine mesh metals allows for innovative design solutions, enabling manufacturers to push the boundaries of traditional production methods. These materials can be fabricated easily into complex shapes and sizes, catering to specific application requirements. As industries continue to evolve, leveraging the advantages of fine mesh metals will be essential for staying competitive.

Tip: To further enhance the effectiveness of fine mesh metals, always conduct thorough testing to ascertain their compatibility with the intended process. This proactive approach can save time and reduce the risk of manufacturing setbacks.

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Fuel filtration systems | Increased fuel efficiency and reduced contaminants |

| Pharmaceutical | Separation and filtration processes | Enhanced product purity and safety |

| Food & Beverage | Brewing and bottling filtration | Improved taste and shelf life |

| Electronics | EMI shielding | Protection against electromagnetic interference |

| Automotive | Catalytic converters | Reduction of harmful emissions |

| Construction | Reinforcement in concrete structures | Increased durability and strength |

Fine mesh metals are gaining significant attention across various industries due to their unique properties and innovative applications. In the aerospace sector, for example, fine mesh metals are utilized in filtration systems to enhance fuel efficiency and reduce emissions. Their lightweight nature combined with high strength makes them ideal for critical components in aircraft, where weight reduction is paramount. Additionally, fine mesh materials are instrumental in the production of heat exchangers, improving thermal management in aviation technology.

The healthcare industry is also reaping the benefits of fine mesh metals, particularly in the creation of advanced medical devices and implants. These materials can be engineered to promote biocompatibility and facilitate faster healing processes. In applications such as stents and surgical meshes, fine mesh metals provide structural integrity while allowing for optimal tissue integration.

Furthermore, the food processing industry employs fine mesh metals in filtration systems, ensuring product purity and safety while maximizing processing efficiency.

As these examples illustrate, fine mesh metals are revolutionizing various fields by enabling technological advancements and enhancing product performance. Their versatility and adaptability make them a vital component in driving innovation across multiple sectors.

When selecting fine mesh materials for various applications, several essential considerations come into play. First and foremost, the material's compatibility with the intended environment is crucial. For example, if the mesh will be used in a harsh chemical setting, opting for stainless steel or specialized alloys can prevent corrosion and ensure durability. Additionally, understanding the specific requirements of the application, such as the size of particles being filtered or the flow rate needed, will guide the choice of mesh size and thickness.

Another key factor to consider is the manufacturing processes involved. Different industries may require specific weave patterns or coatings on fine mesh metals to enhance their performance. For example, a food processing facility may benefit from meshes with FDA-approved coatings that ensure hygiene and safety. Evaluating the mesh's resistance to wear and tear, alongside factors such as thermal stability and tensile strength, will further refine the selection process. By carefully considering these aspects, industries can effectively harness the innovative potential of fine mesh metals, optimizing their use for various applications.

The field of fine mesh metals has seen a significant evolution, with various technologies propelling their applications across multiple industries, from aerospace to food processing. A comparative analysis reveals that technologies such as laser welding, electroforming, and 3D printing offer distinct advantages for creating intricate designs and superior performance.

Laser welding, for instance, allows for precise joints without compromising the structural integrity of the mesh, making it ideal for high-stress environments.

Tip: When selecting fine mesh technology, consider the specific requirements of your application, such as the operating environment and the need for corrosion resistance. This ensures you choose the right process that balances performance with durability.

Moreover, electroforming provides exceptional control over mesh properties, allowing for customization in pore size and thickness. This is particularly beneficial in filtration and biomedical applications where precision is critical. On the other hand, 3D printing of fine mesh metals opens new avenues for producing complex geometries that were previously challenging to achieve using traditional methods.

Tip: Always evaluate the lifecycle costs of the manufacturing processes involved. Sometimes more expensive initial technologies can lead to significant savings or added value over the product’s lifespan.

The future of fine mesh metal applications is being shaped by technological advancements and growing demands across various sectors. Industries such as aerospace, healthcare, and electronics are harnessing fine mesh metals for innovative solutions, paving the way for enhanced performance and efficiency. For instance, in the aerospace sector, lightweight fine mesh materials contribute to fuel savings and improved aerodynamics, while in healthcare, they are crucial in devices such as filters and implants, ensuring safety and efficacy.

When exploring the potential of fine mesh metals, it’s essential to stay ahead of trends. **Tip:** Consider investing in research that focuses on the integration of advanced manufacturing techniques, like 3D printing, which can lead to custom solutions tailored to specific industry needs. Additionally, engaging in collaboration between sectors can foster innovation. **Tip:** Build partnerships with R&D departments or startups to explore unique applications that may not be widely recognized yet. Embracing these trends can position businesses at the forefront of industry advancements, ensuring they remain competitive and relevant.