No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

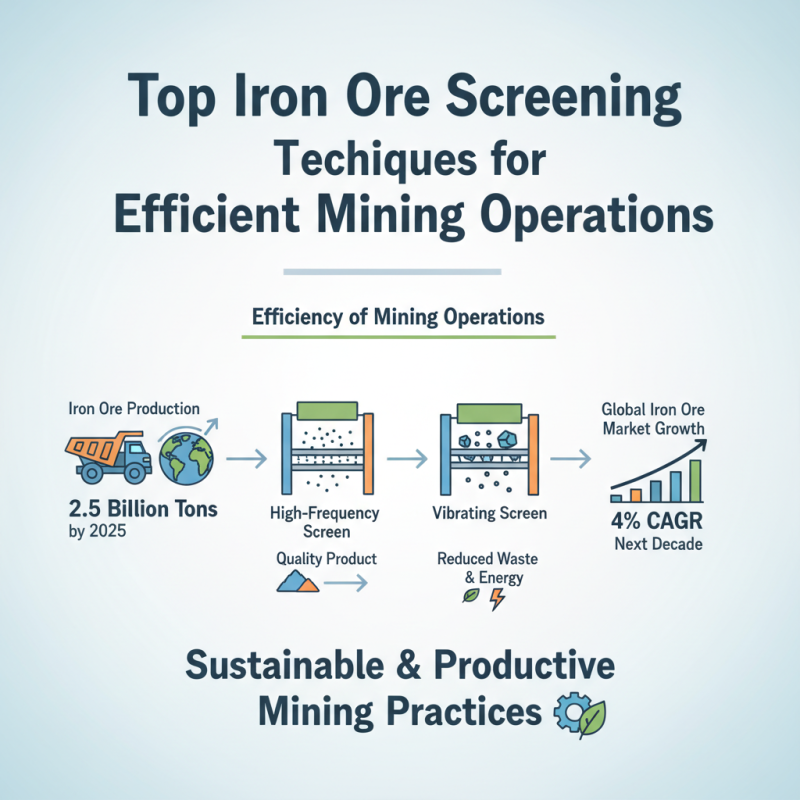

Iron ore screening plays a crucial role in the efficiency of mining operations, significantly impacting the overall productivity and profitability of the industry. According to a report by Mining Intelligence, the global iron ore production is projected to reach over 2.5 billion tons by 2025, with an increasing emphasis on maximizing the yield and minimizing waste. Effective iron ore screening techniques are essential in this context, as they help separate valuable ore from gangue and other impurities, ensuring that only the highest quality material is processed further.

Innovative screening technologies, such as high-frequency screens and vibrating screens, have emerged as vital components of modern mining operations. These methods not only enhance the quality of the final product but also reduce the environmental impact of mining activities by lowering energy consumption and decreasing the volume of waste material. The demand for more efficient iron ore screening processes correlates with the anticipated growth of the global iron ore market, which is expected to expand at a compound annual growth rate (CAGR) of around 4% through the next decade. This ongoing evolution in screening techniques signals a pivotal shift toward more sustainable and productive mining practices.

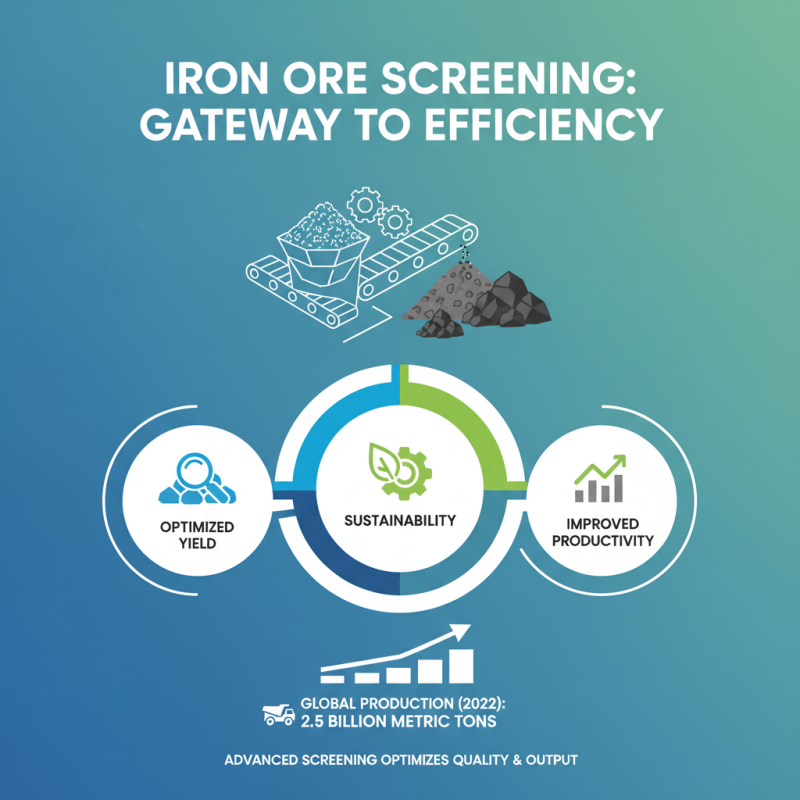

Iron ore screening is a critical component of mining operations, serving as the gateway to efficient resource extraction and processing. As mining companies strive to improve productivity and sustainability, the focus on effective screening techniques has gained prominence. According to reports from the World Steel Association, iron ore production reached 2.5 billion metric tons in 2022, with a significant portion being processed through advanced screening methods to optimize yield and quality.

In essence, screening involves the separation of ore particles based on size and grade, facilitating the removal of impurities and ensuring optimal processing. Recent studies indicate that state-of-the-art screening technologies, such as high-frequency screens and vibrating screens, can improve separation efficiency by up to 30%. These innovations not only enhance the quality of the iron ore extracted but also reduce operational costs by maximizing throughput and minimizing waste. Additionally, utilizing predictive analytics and artificial intelligence in screening processes can further fine-tune operations, allowing for real-time adjustments based on material characteristics.

Efficient iron ore screening also contributes significantly to environmental sustainability within mining operations. By effectively managing the quality of ore being processed, companies can reduce energy consumption in downstream processes. The International Council on Mining and Metals highlights that implementing advanced screening techniques can result in a 15-20% reduction in overall carbon emissions associated with iron ore production. As the industry continues to evolve, the integration of these screening advancements will be pivotal in meeting both economic and environmental objectives in iron ore mining.

Efficient screening techniques in mining

are crucial for optimizing operations and maximizing resource recovery. The process of separating valuable iron ore

from waste materials relies significantly on the effectiveness of screening methods. By employing advanced screening technologies,

mining operators can enhance the accuracy of material separation, ensure higher quality of extracted ore, and minimize

the environmental impact of their operations. This not only contributes to increased productivity but also supports

sustainable practices within the mining industry.

Moreover, the importance of efficient screening techniques extends beyond mere operational efficiency. Properly

implemented screening processes can significantly reduce costs associated with downstream processing, such as grinding

and concentration. By effectively eliminating waste, mining companies can lower their energy consumption and reduce

wear on equipment. Furthermore, improved screening techniques facilitate better compliance with environmental regulations,

as they help mitigate the release of unwanted particles into surrounding ecosystems. This holistic approach not only

boosts the profitability of mining operations but also reinforces the industry's commitment to responsible mining practices.

Iron ore screening is a crucial process that enhances the efficiency of mining operations. Among the most common methods employed are dry and wet screening. Dry screening utilizes vibratory screens to separate iron ore materials based on size without the use of water, making it a cost-effective solution in arid regions. The material is subjected to vibration which allows smaller particles to pass through the mesh while larger materials are retained, thus maximizing the value of the screened ore.

Wet screening, on the other hand, involves the use of water to aid in the separation of iron ore particles. This technique is particularly effective in removing fine particles and impurities that can hinder the quality of the product. In this method, the mixture is passed through a screen while being continuously sprayed with water, ensuring that unwanted materials are washed away. Additionally, this approach can help improve the accuracy of size separation, thus optimizing the overall output of the mining operation.

Beyond these traditional methods, advancements in screening technologies, such as the use of high-frequency screens and advanced simulation modeling, have started to play a significant role in improving screening effectiveness. These innovations allow for better customization and adaptability to various ore types and conditions, ensuring that mining operations can achieve optimal results while maintaining efficiency.

| Screening Method | Efficiency (%) | Application | Advantages | Disadvantages |

|---|---|---|---|---|

| Vibrating Screens | 85 | Primary Screening | High throughput, adjustable speed | High maintenance, noise generation |

| High-frequency Screens | 90 | Fine Screening | Effective for small particles, low energy consumption | Complex operation, limited feeding capacity |

| Trommel Screens | 80 | Bulk Material Screening | Robust design, low operating costs | Limited to coarser materials, potential clogging |

| Static Screens | 75 | Coarse Screening | Simple operation, low power requirement | Lower efficiency, requires manual cleaning |

| Air Classifiers | 88 | Fine Material Separation | No moving parts, precise separation | Requires air supply, sensitive to humidity |

Several factors significantly influence the efficiency of screening operations in iron ore mining. Firstly, the physical properties of the iron ore material being screened play a crucial role. The size distribution, moisture content, and shape of the particles can affect how well the screening process works. For example, finer particles may easily pass through the screen openings while coarser ones might clog or not be separated effectively. Understanding the characteristics of the ore allows for better selection of screening methods and equipment, thereby enhancing overall operational efficiency.

Moreover, the design and configuration of the screening equipment are critical for optimal performance. The angle of the screens, the type of screen media used, and the screening flow rate must all be carefully considered to prevent material build-up and ensure smooth operations. Additionally, the integration of technology, such as automated monitoring systems, can help operators adjust parameters in real time according to changes in feed material consistency or volume, thus maximizing screening efficiency. Regular maintenance and timely inspections of the screening machinery also play a vital role in minimizing disruptions and prolonging equipment life, which ultimately contributes to more efficient mining operations.

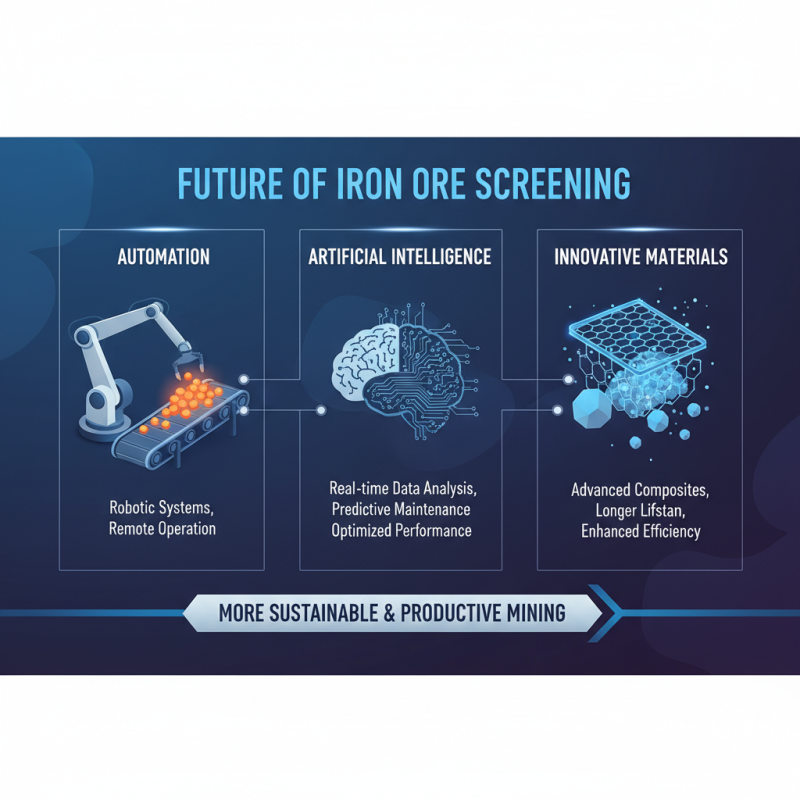

The future of iron ore screening technology is poised for transformation as advancements in automation, artificial intelligence, and innovative materials take center stage. One of the most significant trends is the integration of AI and machine learning algorithms in screening processes. These technologies enable real-time data analysis, allowing operations to adapt quickly to varying ore qualities and conditions. Predictive maintenance powered by AI can reduce downtime and enhance the efficiency of screening equipment, ultimately leading to more sustainable and productive mining operations.

Additionally, innovations in materials science are leading to the development of more durable and efficient screening equipment. The use of composite materials and advanced coatings can increase the lifespan of screens, reducing the need for frequent replacements and repairs. Furthermore, the emergence of mobile screening units equipped with state-of-the-art technology allows for greater flexibility in operations, enabling miners to efficiently assess ore quality directly at the site. As these trends continue to evolve, they promise not only to improve the efficiency of iron ore screening but also to drive sustainability within the mining sector, aligning with global environmental goals.