No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

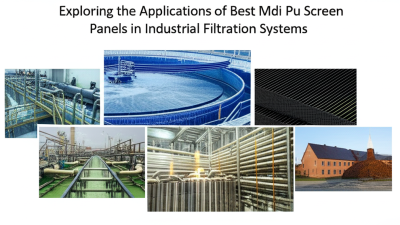

In the increasingly competitive field of mineral processing and industrial filtration, maximizing efficiency and performance is paramount, and one of the critical components in this arena is the Pu Dehydrated Screen. Recent industry reports indicate that effective dehydration can enhance recovery rates by up to 30%, while simultaneously reducing operational costs by 20% through optimized screening solutions. The demand for high-performance screens like the Pu Dehydrated Screen has surged, reflecting a broader trend in the industry toward innovative technologies designed to improve resource recovery and streamline processes. As companies look to adapt to evolving market needs and regulatory pressures, mastering the use of Pu Dehydrated Screens will not only ensure optimal operational performance but also contribute to sustainable practices in mineral processing. This step-by-step guide aims to equip professionals with the necessary insights and techniques to harness the full potential of Pu Dehydrated Screens for superior output and efficiency.

In industrial applications, mastering the performance of Pu dehydrated screens requires a keen understanding of key performance metrics. These metrics serve as critical indicators of how effectively the screens are functioning and highlight areas for potential improvement. First and foremost, the flow rate is a major metric; it measures the volume of material processed per unit time. A higher flow rate often signifies better efficiency and can be a direct reflection of the screen's design and material quality.

Another essential metric is the screen’s separation efficiency, which determines how well the screens are capable of filtering out unwanted particles while allowing desired materials to pass through. By analyzing separation efficiency, operators can fine-tune settings and make adjustments to optimize performance. Additionally, monitoring wear and tear on the screens can provide valuable insights into their longevity and operational costs. Regular maintenance and data collection on these metrics can lead to enhanced productivity and reduced downtime, ensuring that the Pu dehydrated screens deliver optimal results in various industrial situations.

Screen design plays a crucial role in fluid dynamics and solids separation, making it a fundamental aspect for optimizing the performance of Pu dehydrated screens. The geometry of the screen, including the size and shape of openings, directly influences the flow of fluids through the medium. A well-designed screen can ensure the efficient passage of the desired liquid while effectively trapping larger particles and contaminants. This balance is critical for applications in industries such as mining, water treatment, and food processing, where maintaining the quality of output is paramount.

Moreover, the materials used in screen construction significantly affect their performance under varying conditions. Different materials can alter the physical properties of the screen, such as permeability and resistance to wear, which in turn impacts the separation efficiency. By understanding how these factors interact, engineers and operators can fine-tune their screen designs to achieve optimal results, thus enhancing overall productivity. Focusing on the relationship between screen design and fluid mechanics will ultimately lead to improved operational outcomes and reduced downtimes in any application involving solids separation.

| Parameter | Description | Impact on Fluid Dynamics | Impact on Solids Separation |

|---|---|---|---|

| Mesh Size | The size of the openings in the screen | Affects flow velocity and turbulence | Determines particle retention efficiency |

| Screen Material | The composition of the screen | Impacts durability and flow characteristics | Influences wear resistance and maintenance frequency |

| Angle of Inclination | The tilt of the screen surface | Affects gravitational forces and drainage rates | Impacts the separation efficiency of heavier solids |

| Flow Rate | The volume of fluid passing through the screen | Changes the shear stress on materials | Affects the ability to separate and concentrate solids |

| Vibration Frequency | The rate at which the screen vibrates | Enhances material flow and reduces clogging | Improves the efficiency of solids passage through the screen |

In the quest for maintaining optimal performance in PU dehydrated screens, analyzing and enhancing maintenance practices becomes crucial. Reports indicate that regular maintenance can extend equipment lifespan by up to 30%, thereby reducing unexpected downtimes and repair costs. Implementing a proactive maintenance schedule not only maintains efficiency but also aligns with the growing emphasis on sustainability in industrial processes.

To effectively ensure longevity, consider incorporating advanced monitoring technologies. These tools can provide real-time insights into operational conditions, allowing for timely interventions before significant issues arise. Moreover, taking a cue from the environmental evaluations in hybrid separation methods, an integrated approach that combines various maintenance techniques could yield better performance. For instance, utilizing data analytics can help identify patterns that inform maintenance strategies more efficiently.

Tips for Maintenance:

In the quest for optimal performance in PU dehydrated screens, implementing advanced technologies is crucial. As industries continue to advance, so must the methods we utilize for efficiency. Investing in state-of-the-art monitoring systems can provide real-time data on the operational efficiency of your screens, allowing for immediate adjustments and minimizing downtime.

**Tip:** Regularly update software systems to incorporate the latest advancements in technology. This ensures that your equipment is always operating at peak efficiency and can often lead to unexpected cost savings.

Furthermore, integrating AI-driven analytics can greatly enhance your understanding of the performance metrics of your dehydrated screens. By analyzing patterns and predicting maintenance needs, businesses can avoid unexpected breakdowns and extend the lifecycle of their equipment.

**Tip:** Consider conducting periodic training for your team on these new technologies. Empowering staff with knowledge on how to leverage advanced tools will foster a more responsive and capable workforce, ultimately leading to greater operational success.

The economic benefits of achieving optimal performance in PU dehydrated screens operations cannot be overstated. By focusing on effective processes and maintenance strategies, companies can drastically reduce operational costs while simultaneously enhancing productivity. The right screening technology significantly minimizes material loss and maximizes throughput, translating to increased profitability. Investing in high-quality PU screens that are well-maintained ensures higher efficiency in separation processes, ultimately leading to reduced energy consumption and labor costs.

Moreover, optimizing the performance of PU dehydrated screens also contributes to sustainability initiatives. Higher efficiency in operations means less waste generation and a lower carbon footprint, aligning with modern environmental standards. Companies that prioritize optimal screen performance can enjoy not only financial gains but also positive branding as environmentally responsible organizations. This dual benefit of cost reduction and enhanced sustainability positions businesses favorably in a competitive landscape, enabling them to meet both market demands and regulatory requirements effectively.