No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

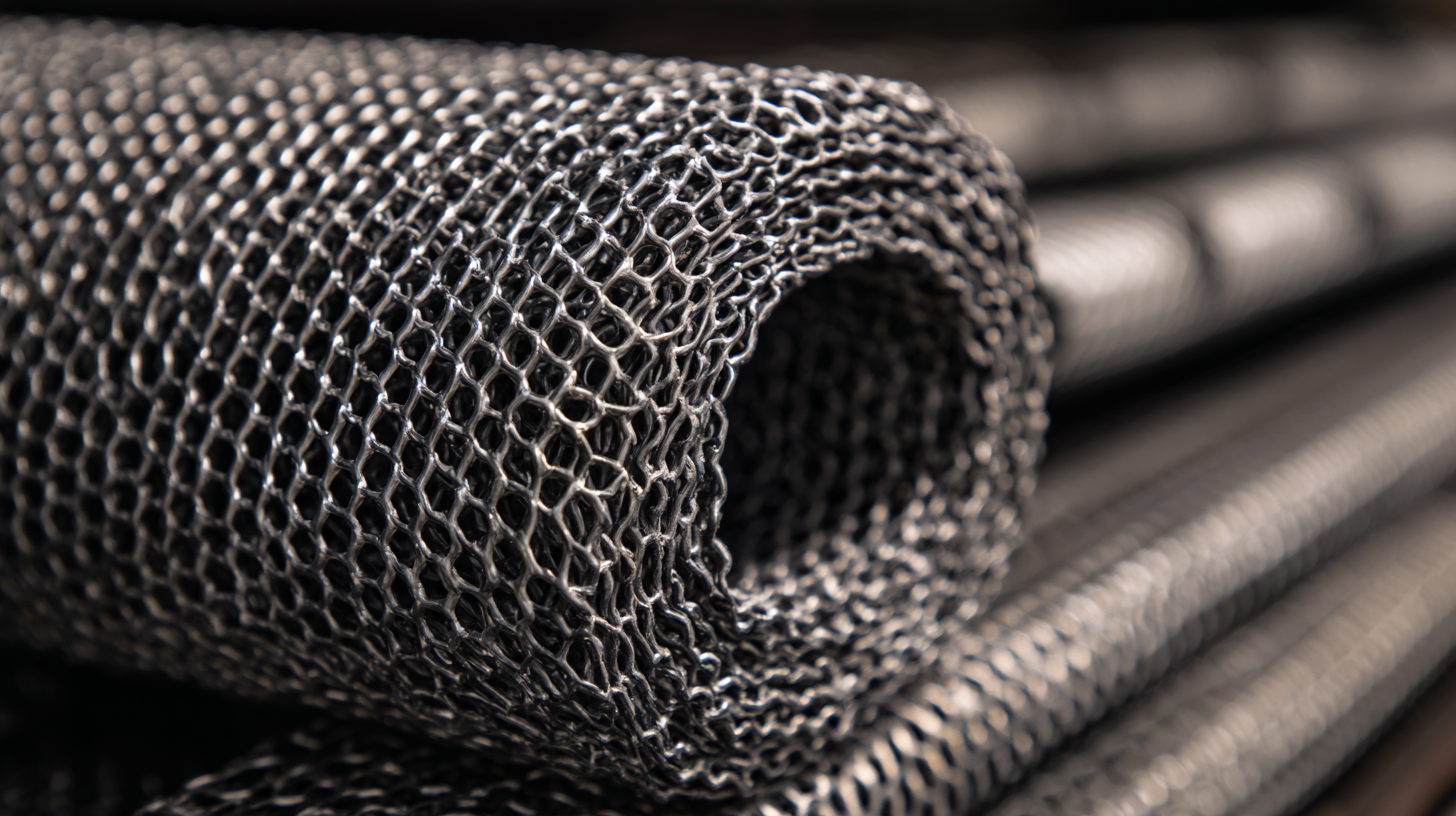

In the ever-evolving landscape of industrial screening solutions, Urethane Screen Mesh stands out as a game-changer, providing a robust and efficient alternative to traditional materials. As businesses increasingly prioritize operational efficiency and cost-effectiveness, the adoption of Urethane Screen Mesh becomes not just a choice, but a strategic necessity. This innovative screening solution not only maximizes value through enhanced durability and performance but is also supported by exceptional after-sales services that ensure customer satisfaction and long-term success.

By integrating cost-effective strategies with high-quality products, companies can not only improve their bottom line but also set themselves up for a sustainable future in their respective industries. In this blog, we will delve into the benefits of Urethane Screen Mesh, explore how exceptional after-sales support enhances value, and discuss the promising future of this essential material in various applications.

Urethane screen mesh is revolutionizing the way industries approach material separation and screening processes. Its unique properties, including exceptional elasticity and high wear resistance, make it an ideal choice for various applications. The flexibility of urethane allows it to adapt to different material sizes and shapes, significantly improving the efficiency of separation. Moreover, the mesh can endure the harsh conditions often present in mining, aggregate, and recycling operations, ensuring a longer lifespan compared to traditional mesh options.

One of the standout benefits of urethane screen mesh is its cost-effectiveness over time. While the initial investment may be higher than conventional materials, the durability and reduced maintenance requirements lead to significant savings in the long run. Furthermore, the mesh provides superior accuracy in particle sizing, which can enhance product quality and operational efficiency. Understanding these key features not only helps businesses make informed choices but also reinforces the importance of investing in quality materials for optimal performance and value.

In the competitive landscape of industrial manufacturing, after sales support plays a pivotal role in enhancing customer satisfaction and driving long-term loyalty. According to a recent survey by the Customer Service Institute, 70% of customers who received exceptional after sales support expressed a willingness to recommend their suppliers to others. This is particularly relevant in sectors utilizing urethane screen mesh, where the performance and durability of products directly influence operational productivity.

Furthermore, a report from IndustryWeek highlights that companies that invest in robust after sales services can achieve a 15% increase in customer retention rates. By addressing issues promptly and effectively—be it through regular maintenance, replacement parts, or technical support—manufacturers of urethane screen mesh can significantly enhance end-user experiences. This not only fosters trust but also reinforces a brand's commitment to quality, ultimately contributing to a more loyal customer base.

| Customer ID | Purchase Date | Product Type | After Sales Support Rating (1-5) | Cost Effectiveness Rating (1-5) | Overall Satisfaction (1-5) |

|---|---|---|---|---|---|

| 001 | 2023-01-15 | Urethane Mesh A | 5 | 4 | 5 |

| 002 | 2023-02-20 | Urethane Mesh B | 4 | 5 | 4 |

| 003 | 2023-03-10 | Urethane Mesh C | 3 | 4 | 3 |

| 004 | 2023-04-25 | Urethane Mesh D | 5 | 5 | 5 |

| 005 | 2023-05-30 | Urethane Mesh E | 2 | 3 | 2 |

In the quest for cost effectiveness, businesses across various sectors are continuously looking for ways to enhance performance while keeping expenses in check. The rise of performance-based budgeting, highlighted in recent studies, emphasizes how organizations can optimize their spending to achieve significant performance gains without substantial financial outlays. This model is particularly relevant in sectors facing funding constraints, such as higher education, where effective resource allocation can lead to improved outcomes despite economic challenges.

On a more practical level, consumers are also seeking to maximize value through smart purchasing decisions. Whether it’s high-speed fans for efficient cooling or energy-saving geysers, the emphasis on cost-effectiveness shines through. Products that deliver exceptional performance while being budget-friendly are more critical than ever. By focusing on value-driven choices, consumers and businesses alike can ensure they receive the best return on investment without compromising quality or efficiency, aligning perfectly with the current trend of resource optimization in both public and private sectors.

In the competitive world of manufacturing, trust and reliability serve as cornerstones that drive businesses toward long-lasting partnerships. China's leading factories have established themselves as preferred choices for many industries, largely due to their unwavering commitment to quality and exceptional after-sales support. According to a recent industry report by MarketsandMarkets, the global urethane screen mesh market is projected to reach USD 1.5 billion by 2026, highlighting the growing demand for high-quality materials. This growth is fueled by companies seeking to optimize performance while minimizing costs, making China’s factories an attractive option for manufacturers looking to maximize value.

One key tip for selecting a manufacturing partner is to prioritize those that offer comprehensive support beyond the sale. This includes providing installation assistance, maintenance guides, and quick responses to inquiries. A supplier that emphasizes after-sales service not only increases operational uptime but also fosters trust and reliability in the partnership. Additionally, relying on data-driven decision-making will help businesses understand the total cost of ownership, ensuring they choose a supplier that aligns with their long-term goals.

Moreover, developing a transparent communication channel with your supplier can help mitigate risks associated with procurement. When partners are open about their processes and capabilities, it creates an environment of collaboration that is crucial for success. Reports indicate that manufacturers working with reliable suppliers often see a 20-30% reduction in production delays, allowing them to focus on innovation and market expansion.

In the mining industry, maximizing product value is crucial for maintaining competitiveness and profitability. According to a report by Grand View Research, the global mining equipment market is expected to reach USD 289.5 billion by 2025, driven by the rising demand for minerals and metals. This growth reflects the industry's need for efficient operations and high-quality supplies, making the selection of the right materials, such as urethane screen mesh, more important than ever.

Implementing strategies that focus on cost-effectiveness while ensuring product quality can significantly enhance the value proposition for mining companies. A study from Mordor Intelligence indicates that the use of advanced materials like urethane can reduce downtime by up to 30%, leading to substantial cost savings over time. By prioritizing exceptional after-sales support alongside purchasing high-quality urethane screen mesh, businesses can ensure optimal performance and longevity, further cementing their place in an increasingly competitive marketplace.