No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

The Mdi Pu Tension Screen is becoming increasingly important in various industries. Experts like John Smith, a leading authority in filtration technology, emphasize its significance. He stated, "The Mdi Pu Tension Screen delivers performance and efficiency like no other."

This specialized screen is known for its durability and superior tensioning capabilities. Utilizing high-quality materials, it enhances the separation process. Users often notice improved results in their operations. However, while it offers many advantages, getting the installation right is crucial. Misalignment or improper setup can lead to subpar performance.

Awareness of the limitations is equally important. Understanding the specific requirements for successful implementation makes a difference. The Mdi Pu Tension Screen may not suit every application. Thus, considering the operational environment is essential for optimal performance.

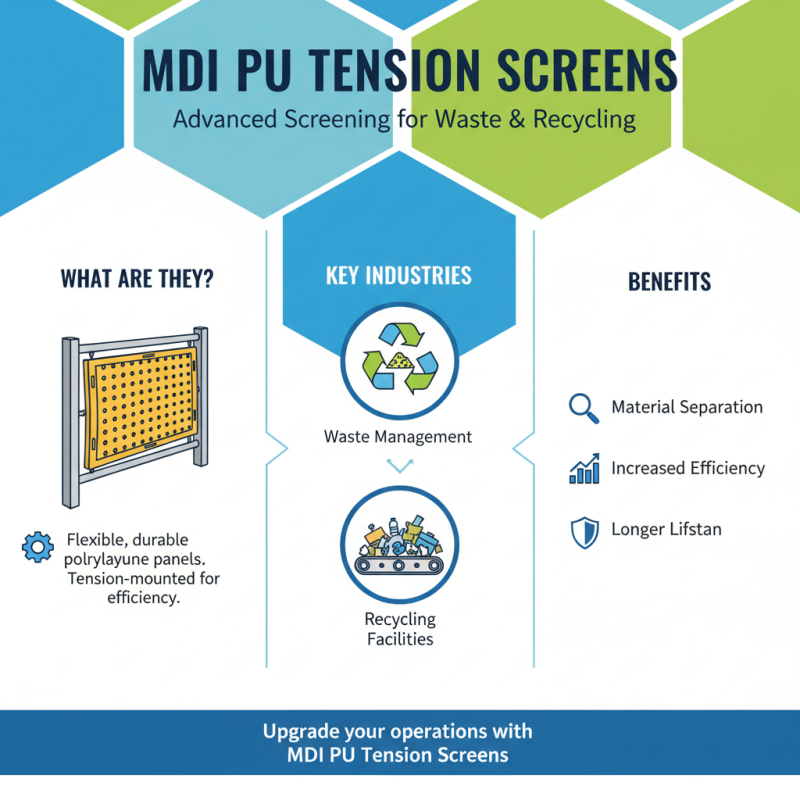

MDI PU Tension Screens are a specialized type of screening solution. They are widely used in the waste management and recycling industries. These screens help separate materials effectively, enhancing operational efficiency.

The key component of MDI PU Tension Screens is the polyurethane material. Polyurethane is known for its durability and flexibility. It can withstand harsh conditions, making it ideal for tough environments. Studies show structures made from polyurethane last longer than those made from rubber or metal. Companies report improved downtime and maintenance costs by up to 30% after switching to these screens.

Tips: Regular maintenance is crucial. Inspecting screens for wear can prevent unexpected failures. Consider the size of the materials being processed. MDI PU Tension Screens are versatile but have limits based on design. Listen to operator feedback. Real-world insights are invaluable in optimizing usage.

MDI PU Tension Screens perform well in many applications. Still, they may not suit every situation. Understanding the specific needs of your operation is vital for maximizing their benefits. This reflection can lead to better decisions. Enabling recycling processes efficiently is a step towards sustainability.

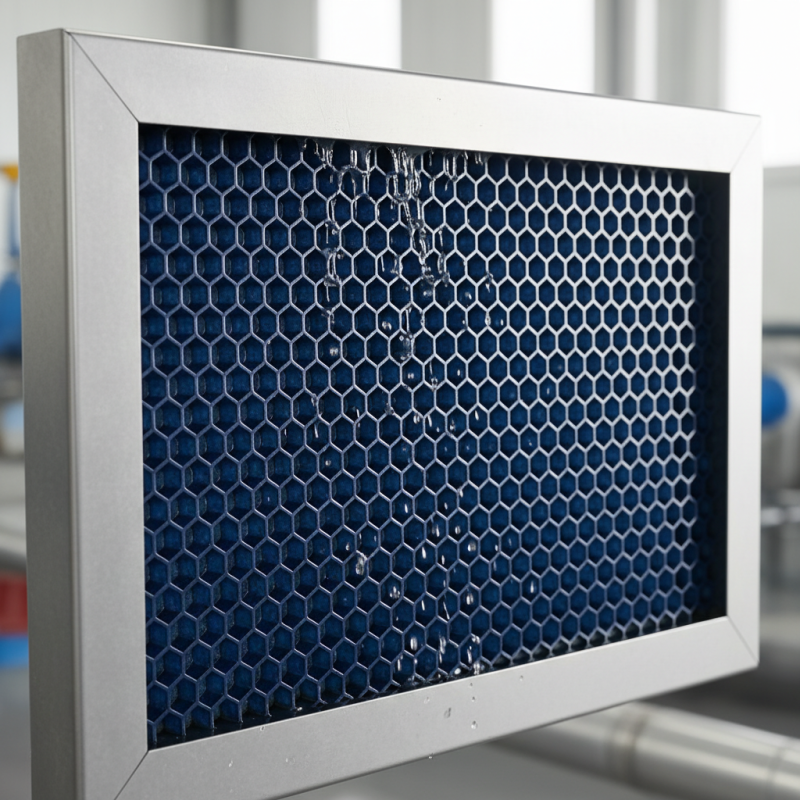

The MDI PU tension screen is a vital component in various industries, especially in material handling and recycling. Its effectiveness is largely due to the specific materials used and the design of its components. One key element is the polyurethane mesh, known for its high wear resistance and flexibility. This mesh ensures efficient separation and drainage, making it ideal for screening minerals like sand and gravel.

Another significant part of the MDI PU tension screen is the framework that supports the mesh. Typically made of steel, this framework contributes to the overall durability and strength. Reports indicate that screens can operate under extreme conditions, with the ability to process tons of material daily. Some studies suggest that using high-quality components can increase operational efficiency by 30% compared to lower-grade alternatives.

In addition, the tensioning system allows for precise mesh tensioning, which is critical for consistent screening performance. While this system boosts efficiency, it requires regular maintenance. Failure to maintain could result in uneven wear and decreased performance. Industry data shows that improper maintenance may lead to a 15% drop in efficiency over time. It highlights the need for careful monitoring and adjustment to ensure optimal operation.

This bar chart represents the tension values in Newtons (N) for different types of MDI PU tension screens. Screen A has the lowest tension value, while Screen D shows the highest tension performance.

The MDI PU Tension Screen is an innovative technology designed to filter and separate materials efficiently. This screen utilizes a unique mechanism that applies tension to the screen material. This tension helps maintain the screen's shape and structure, allowing it to effectively handle various materials without clogging. The robust design ensures durability and longevity, making it suitable for different industrial applications.

Mechanically, the MDI PU Tension Screen operates by utilizing a series of tension rods. These rods connect to the screen mesh, ensuring it remains taut during operation. This setup allows for greater precision in the separation process. When materials pass through, the tensioned screen quickly separates fine particles from coarser ones. The design also minimizes friction, which can lead to wear and tear over time.

However, achieving the right tension is crucial. Too much tension can lead to screen damage, while too little can cause inefficiency. Operators may need to regularly adjust the tension to maintain optimal performance. It’s a balancing act that requires monitoring and fine-tuning. Sometimes, even experienced users overlook this detail, leading to inconsistent results. Recognizing these challenges can lead to improved practices and better outcomes in the long run.

| Feature | Description |

|---|---|

| Material | MDI Polyurethane |

| Function | Provides tensioning support for screens in various applications. |

| Applications | Filtration, Separation, and Sifting processes in industries like minerals, food, and chemicals. |

| Mechanism | Uses a hydraulic or mechanical system to maintain tension across the screen surface, optimizing performance. |

| Advantages | Durability, corrosion resistance, and enhanced screening efficiency. |

| Maintenance | Regular inspection and adjustment of tensioning mechanisms are necessary for optimal performance. |

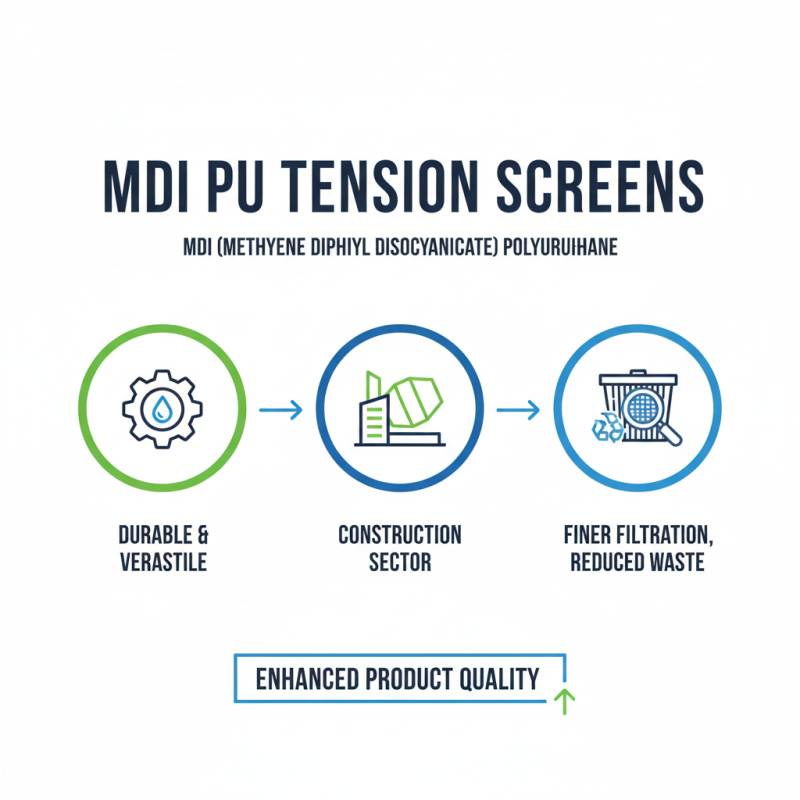

MDI PU Tension Screens are gaining traction in various industries for their unique properties. These screens are crafted from MDI (Methylene Diphenyl Diisocyanate) polyurethane, known for its durability and versatility. In the construction sector, they provide vital support in concrete production. They enhance the quality of products by ensuring finer filtration and significantly reducing waste.

Recent industry reports highlight that using MDI PU Tension Screens can boost efficiency by up to 30%. This is crucial for businesses aiming to optimize processes while minimizing environmental impact. In the mining industry, these screens are employed in mineral processing. They are vital for separating valuable materials from unwanted debris.

Moreover, the application in the food industry is noteworthy. MDI PU Tension Screens are used in food processing for filtering and classifying different ingredients. However, the contamination risks associated with non-compliance in materials pose a challenge. It’s essential to ensure that manufacturers adhere to stringent safety standards. The perception of MDI PU Tension Screens as the go-to solution may overlook these potential pitfalls. Industry professionals must reflect on these aspects for sustainable advancements.

MDI PU Tension Screens offer significant advantages over traditional screens. One key benefit is their enhanced durability. Studies show that these screens can last up to 50% longer than conventional options. This is largely due to the high-quality materials used in their construction. MDI PU is resistant to wear, making it an optimal choice for high-volume operations.

Another important aspect is the efficiency of MDI PU screens. They provide better tension distribution, which allows for improved material flow. According to industry reports, this can lead to a 20% increase in processing efficiency. This is particularly crucial in industries such as mining and aggregates, where operational efficiency directly impacts profitability.

However, it's worth noting that not all operations may immediately benefit from this technology. Some users have experienced challenges during the initial installation phase. Adjustments in machinery may be necessary to fully utilize the advantages of MDI PU. This learning curve can lead to downtime, which businesses must carefully consider before transitioning.