No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

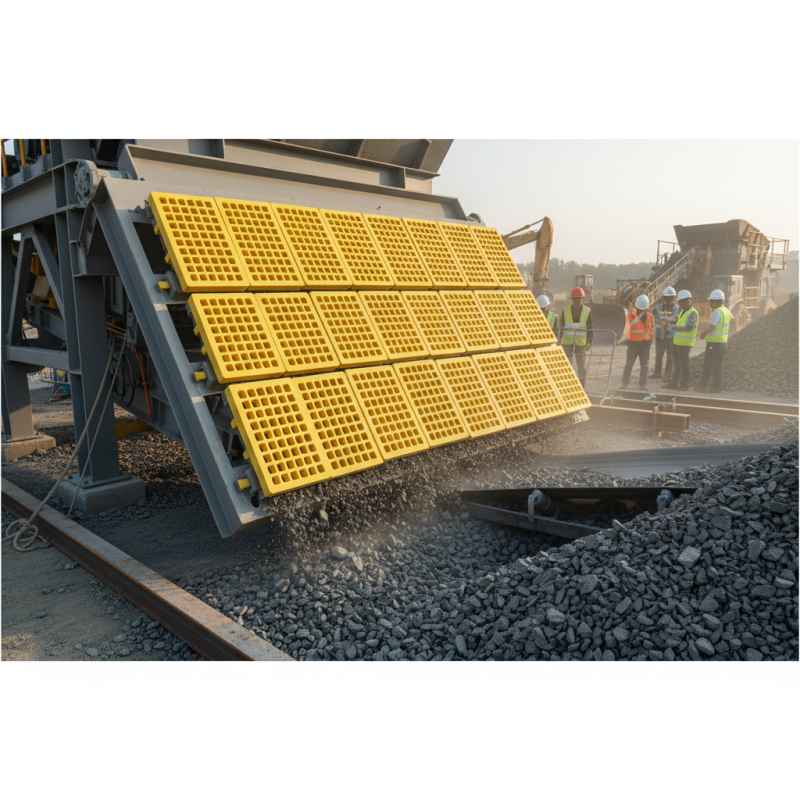

The construction industry is constantly evolving. One innovative solution that has gained attention is the Pu Screen Panel. This panel plays a crucial role in enhancing construction processes. It contributes to the efficiency and safety of various projects.

A Pu Screen Panel is designed to separate materials, offering flexibility in usage. It is lightweight yet durable. Many builders appreciate how it simplifies the handling of aggregates and other substances. This panel can withstand harsh conditions, but it’s not flawless.

Some users have reported durability concerns under extreme stress. Additionally, installation might require skilled labor for optimal results. Understanding the mechanics of a Pu Screen Panel involves looking beyond its advantages. It is essential to evaluate both its strengths and weaknesses in the field.

A PU screen panel is an essential tool in construction. Made from polyurethane, it offers durability and flexibility. These panels are often used in various applications, including scaffolding, formwork, and protective barriers. They are lightweight, making them easy to handle on-site. However, their effectiveness relies on proper installation and maintenance.

In practical use, a PU screen panel offers superior filtration. It allows air and light to pass while blocking unwanted elements like debris. This feature creates a safer work environment. Yet, there are challenges. Over time, wear and tear can diminish their performance. Inspecting and replacing damaged panels is crucial to maintain safety.

The design of the PU screen panel includes various sizes and shapes. This versatility allows for custom solutions on construction sites. However, selecting the right panel can be complex. It requires careful consideration of the specific project's needs. Mistakes in these decisions can lead to inefficient use or safety hazards. Thus, understanding the functionality and maintenance of PU screen panels is imperative for successful construction projects.

Pu screen panels play a significant role in construction projects. They are primarily made from polyurethane material. This composition gives them durability and flexibility, making them suitable for various applications. The lightweight nature allows for easy handling on job sites. However, the blend of materials can vary greatly based on the intended use.

In addition to polyurethane, these panels often include additives for enhanced performance. Some panels may have reinforcements to withstand heavy loads. The manufacturing process can impact the quality of the screen. There's a notable difference in resilience between different production methods. It's essential to choose the right panel for a specific construction task to avoid potential failures.

Attention to detail in material selection is crucial. Each project demands unique specifications. A miscalculation in material choice can lead to structural issues. Some panels may not provide the expected outcomes when exposed to harsh environmental conditions. This requires careful consideration and, at times, a bit of trial and error in sourcing the best options. Embracing this learning process can lead to better results in the long run.

| Dimension | Value |

|---|---|

| Material Composition | Polyurethane, Steel Wire, Reinforcing Agents |

| Typical Thickness | 10-20 mm |

| Weight per Square Meter | 5-10 kg/m² |

| Color Options | Black, Yellow, Customized Colors |

| Applications | Construction Sites, Mining Operations, Environmental Controls |

| Advantages | Durability, UV Resistance, Ease of Installation |

| Disadvantages | Higher Cost Compared to Traditional Materials |

Pu screen panels play a vital role in construction projects. These panels serve multiple purposes, including separating different areas and enhancing safety. They are typically made from polyurethane, which offers flexibility and durability. This material can withstand various weather conditions, making it suitable for both indoor and outdoor use.

In practical terms, pu screen panels help keep sites organized. Construction workers can easily identify zones, reducing accidents. These panels can also improve airflow and visibility on-site. However, their effectiveness relies on proper installation. Poor positioning might compromise functionality. It’s essential for teams to communicate regarding placement and adjustments.

While pu screen panels enhance efficiency, their maintenance is often overlooked. Regular checks are necessary to ensure they remain effective. A neglected panel can become a liability. In the end, the utility of pu screen panels relies heavily on consistent oversight and proactive management within the construction environment.

Pu screen panels are gaining popularity in construction. These panels are lightweight yet durable. This combination makes them ideal for various building applications. They provide excellent ventilation while maintaining structural integrity. Many builders prefer them for their ease of installation.

Using Pu screen panels offers several advantages. They enhance energy efficiency. The panels can reduce the need for additional heating and cooling, leading to lower energy costs. Moreover, they are resistant to corrosion and moisture. This quality extends their lifespan significantly, reducing the need for frequent replacements.

Tips: Always consider the specific building environment before installation. Ensure the panels are compatible with other materials used. Regular maintenance checks are essential to avoid unexpected issues. This practice can save time and money in the long run. Reflect on your past experiences with different materials; learning can lead to better decisions in future projects.

Pu screen panels are increasingly used across construction sites for their durability and efficiency. Proper installation is crucial for maximizing their potential. The panels are lightweight, making them easy to maneuver. They can be installed on various structures, ensuring adaptability. However, improper fastening can lead to issues. It's essential to follow guidelines strictly to avoid future problems.

Maintenance is another critical aspect. Regular inspection helps identify wear or damage. Studies show that frequent checks can extend the lifespan of pu screen panels by up to 25%. Neglecting maintenance can lead to significant repair costs. Cleaning the panels with appropriate methods is necessary to prevent staining or deterioration. Replacing a damaged panel promptly is vital, as delays can compromise safety.

Some users report that finding the right tools for installation can be challenging. This often leads to rushed jobs. Ensuring all equipment is available before starting can mitigate this issue. Workers should receive training on handling panels to avoid mistakes. A focus on proper techniques can reduce risks and enhance performance on site.