No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

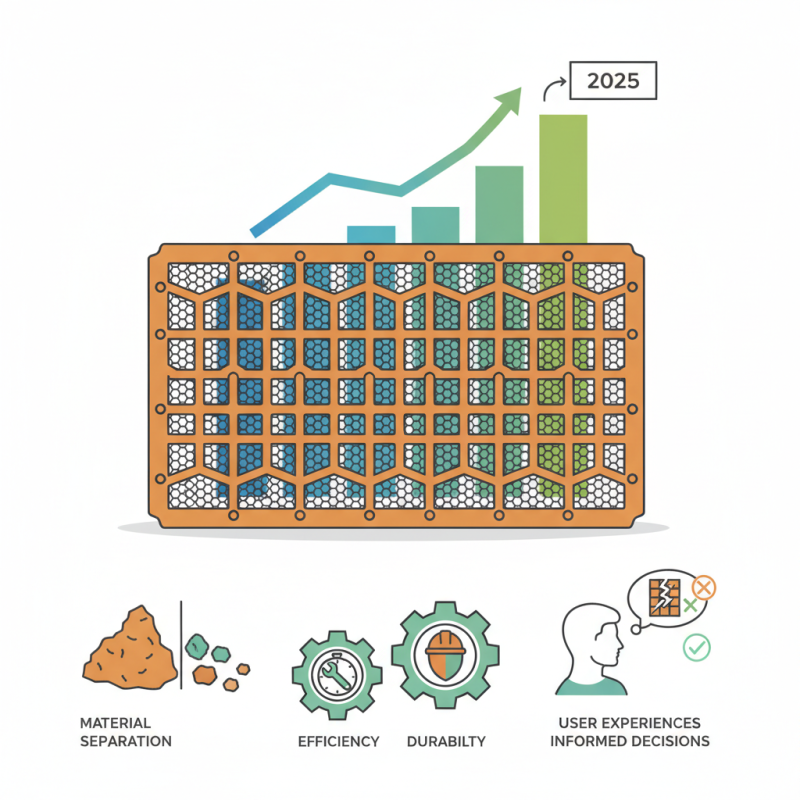

The Pu Screen Panel has become a crucial component in various industrial applications, particularly in mining and construction. Industry reports indicate that the global market for polyurethane screen panels is expected to reach $2 billion by 2025, driven by demand for durable and efficient solutions. Experts highlight the importance of this technology for its effectiveness in separating materials.

John Smith, a respected authority in the field, states, "The Pu Screen Panel significantly enhances operational efficiency and reduces downtime." This emphasizes its role in improving productivity across industries that rely on screening processes. However, it's essential to recognize potential shortcomings. While the panels are effective, their performance can vary under different environmental conditions.

In practice, many users have reported mixed experiences. For instance, some panels may not withstand extreme wear, leading to costly replacements. Thus, understanding the nuances of using a Pu Screen Panel is vital for informed decision-making. Detailed assessments and user feedback can help mitigate these risks and enhance the product's value in real-world applications.

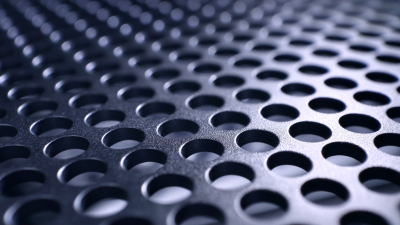

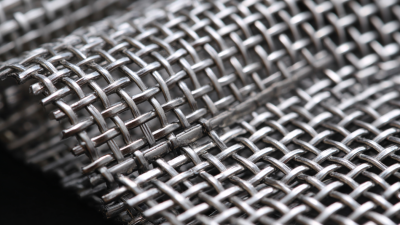

A PU screen panel is a type of filtration system commonly used in various industries. PU stands for polyurethane, a flexible material known for its durability and resistance. These panels help separate solids from liquids, making them essential in processes like wastewater treatment and mineral processing.

Many factories utilize PU screen panels for their efficiency. They provide excellent screening performance, allowing only desired particle sizes to pass through. This ensures the quality of the product remains high. However, improper installation can lead to inefficiencies. Regular maintenance is also crucial. Dirty panels can hinder performance, affecting overall operations.

Tip: Always check the panel for wear and tear. Frequent inspections can prevent costly breakdowns.

Choosing the right mesh size is vital. A too fine mesh can clog quickly. Conversely, a coarse mesh may not filter effectively. Finding the optimal balance is key.

Tip: Keep a journal of performance. This helps in identifying trends and issues over time. Regular analysis can guide adjustments and enhance productivity.

Pu screen panels are crucial in various industrial applications. They are primarily made from polyurethane, a versatile material known for its durability and flexibility. This polymer provides excellent resistance to wear and corrosion, which is vital in harsh environments. The manufacturing process involves careful selection of raw materials to ensure product quality.

Recognizing the specific needs for filtration and separation tasks enhances the design of these panels. Processes often include precise molding techniques that shape the panels accurately. Quality control measures are essential to detect flaws. Sometimes, these panels fail to perform due to overlooked details during production.

In addition to polyurethane, additives may be incorporated for improved performance. These can include colorants or reinforcing agents. However, balancing these components is tricky. A miscalculation can lead to a decline in structural integrity. The complexity of the manufacturing processes often requires ongoing evaluation to optimize performance.

| Dimension | Details |

|---|---|

| Material | Polyurethane (PU) |

| Applications | Mining, Aggregate Processing, Recycling |

| Manufacturing Process | Injection Molding, Pour Casting |

| Benefits | High Durability, Wear Resistance, Lightweight |

| Screen Types | Static Screens, Vibrating Screens |

| Properties | Chemical Resistance, Flexibility, Impact Resistance |

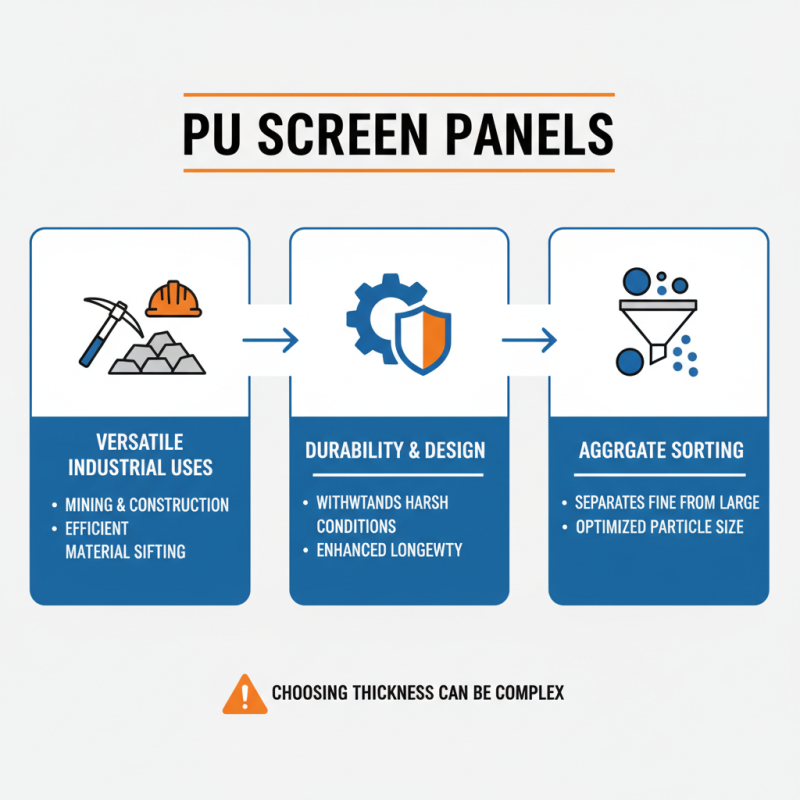

Pu screen panels are versatile tools in many industries. They are commonly used in mining and construction for their ability to sift materials. The panels allow for efficient sorting of aggregates, helping to separate finer particles from larger ones. The design of these panels enhances their durability, which means they can withstand harsh conditions. However, the selection process for the right panel thickness can be tricky.

In agriculture, Pu screen panels serve different purposes. They are used in seed cleaning and sorting processes. These panels must meet certain standards to ensure they do not damage seeds during processing. The flexibility of the material allows for a range of hole sizes, catering to various crops. Yet, it’s essential to regularly assess the wear and tear on these panels.

When it comes to waste management, Pu screen panels play a crucial role in recycling systems. They help in separating recyclable materials from waste effectively. However, the efficiency can vary based on the type of waste being processed. There’s always a need to refine the methods used for better performance. Ultimately, while Pu screen panels are incredibly useful, ongoing evaluation and adaptation are vital for maintaining their effectiveness in all applications.

Pu screen panels are gaining popularity in various industries due to their performance metrics.

Durability is one of their main selling points.

These panels can withstand harsh conditions without losing structural integrity. They resist wear and tear

more effectively than traditional materials.

Efficiency is another key characteristic.

Pu screen panels often enhance productivity. For example, they can filter materials with precision,

reducing waste. This leads to lower operational costs over time. Businesses are increasingly recognizing

these benefits. However, not all panels perform equally. Quality can vary significantly between suppliers.

Tip: When selecting a Pu screen panel,

consider the specific requirements of your application. Test different options to find the best fit.

Much of the durability relies on proper installation. A poorly installed panel may not perform to expectations.

Regular maintenance is crucial too. Some users overlook this aspect, leading to premature failure.

Tip: Schedule routine inspections to

catch potential issues early. This simple step can save significant time and resources.

Understanding how to utilize Pu screen panels efficiently can provide a competitive edge. Focus on

durability and performance

to maximize your investment. Small adjustments can lead to substantial improvements.

The demand for PU screen panels is on the rise. Industries are increasingly adopting these panels for their lightweight and durable properties. Various sectors like construction, manufacturing, and agriculture utilize them for filtration and separation tasks. As more industries recognize their benefits, market trends indicate robust growth.

One key aspect driving this growth is the push for sustainable materials. PU screen panels are often more eco-friendly compared to traditional options. Companies are starting to integrate these panels into their operations. They seek to reduce waste and improve efficiency. As this awareness spreads, the demand is expected to climb.

**Tips:** When considering PU screen panels, evaluate their suitability for your specific needs. Look for features like temperature resistance and chemical compatibility. Regularly assess your existing systems to identify areas for improvement. Small adjustments can lead to significant benefits.

The chart above illustrates the projected demand for PU screen panels from 2023 to 2028, showing a steady increase in demand as industries recognize the benefits and applications of PU screen panels.