No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

When it comes to achieving optimal filtration efficiency, selecting the appropriate fine mesh is crucial for various industries, including food processing, pharmaceuticals, and water treatment. According to a report by MarketsandMarkets, the global filtration market is projected to reach $40 billion by 2027, emphasizing the growing importance of effective filtration solutions. Fine mesh materials play a vital role in this landscape, offering precision and reliability in separating particles from liquids and gases. However, with numerous options available, making the right choice can be overwhelming. Understanding the intricacies of fine mesh—including its material composition, mesh size, and application—will not only enhance filtration performance but also contribute to the overall efficiency and sustainability of operations. In this article, we will explore seven essential tips for choosing the right fine mesh to elevate your filtration system's efficiency to new heights.

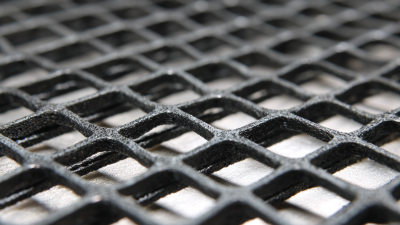

When it comes to filtration, the choice of fine mesh material is critical for achieving optimal efficiency. Various types of fine mesh materials such as

nylon,

polyester, and

stainless steel offer distinct advantages depending on the application. For instance, nylon mesh is favored in the food and beverage industry due to its corrosion resistance and versatility, while polyester meshes are often used in chemical processing because of their excellent tensile strength and durability. According to the Filtration & Separation magazine, the global demand for filtration media is expected to grow at a CAGR of 5.4% until 2025, which underscores the importance of selecting the right material for specific filtration needs.

When it comes to filtration, the choice of fine mesh material is critical for achieving optimal efficiency. Various types of fine mesh materials such as

nylon,

polyester, and

stainless steel offer distinct advantages depending on the application. For instance, nylon mesh is favored in the food and beverage industry due to its corrosion resistance and versatility, while polyester meshes are often used in chemical processing because of their excellent tensile strength and durability. According to the Filtration & Separation magazine, the global demand for filtration media is expected to grow at a CAGR of 5.4% until 2025, which underscores the importance of selecting the right material for specific filtration needs.

Stainless steel meshes, known for their robustness and high-temperature resistance, are frequently utilized in industrial applications and harsh environments. Reports from the Technical Association of the Pulp & Paper Industry indicate that stainless steel filtration accuracy can reach as low as 1 micron, making it ideal for applications requiring high precision. Each type of fine mesh brings unique properties to the table, and understanding these differences is essential for industries aiming to improve their filtration processes and efficiency. Working with the right material not only enhances performance but also prolongs the lifespan of filtration systems, ultimately leading to cost savings over time.

When selecting fine mesh for optimal filtration efficiency, several key factors must be considered to ensure you meet your specific needs. First and foremost, the mesh size is critical. According to a report by the Industrial Filtration Society, finer meshes (usually below 100 microns) are essential for applications requiring the removal of small particles, such as in the food and beverage industry, where contamination risks need to be minimized. This level of filtration can capture particles as small as 30 microns, thus elevating the purity of the final product.

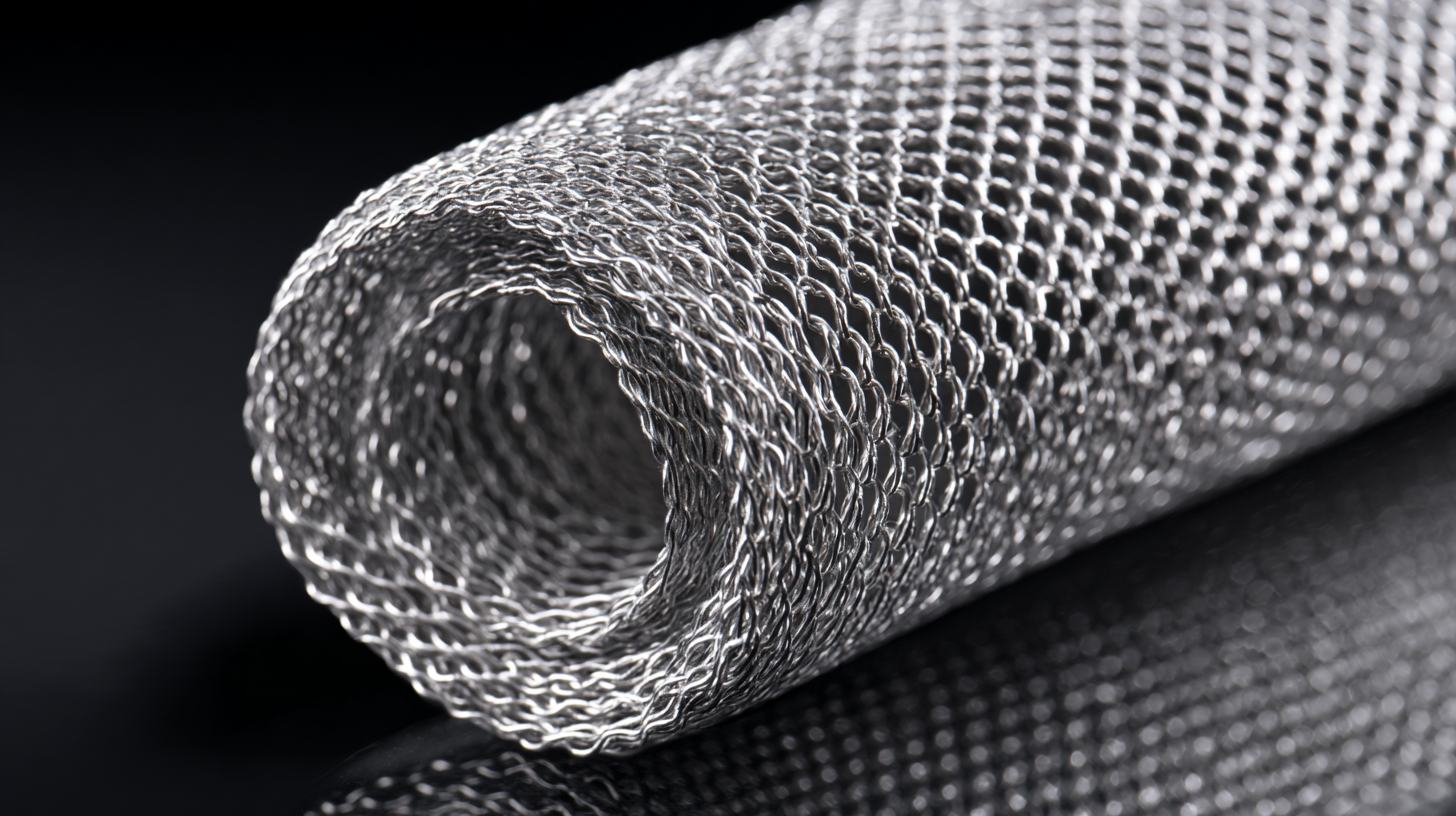

Another significant factor is the material of the mesh. For example, stainless steel is often recommended for its corrosion resistance and durability, particularly in environments involving chemicals or heat. A study by the Filtration Research Group indicates that stainless steel meshes can last up to five times longer than synthetic alternatives in extreme conditions. Additionally, the weave pattern affects both the filtration performance and flow rate. A tight weave can improve filtration efficiency but may also increase pressure drop across the mesh, influencing the overall system efficiency. Making an informed choice by considering these factors can lead to enhanced filtration results tailored to your operational needs.

When selecting the right fine mesh for optimal filtration efficiency, understanding the role of mesh thickness is crucial. Recent studies highlight that filtration performance is significantly influenced by the physical properties of the mesh, including thickness and layer structure. For instance, a comparative analysis of depth filter media cartridges demonstrated that variations in pleat count and layer structure directly affected particle capture efficiency, with thicker layers often providing better retention of larger particulates while requiring a fine balance to avoid restricting flow rates.

In addition to traditional applications like liquid filtration, emerging technologies are also addressing critical issues such as microplastic contamination. For example, citizen science studies have shown that specific washing machine filters can effectively capture microfibers from domestic wastewater, emphasizing the importance of mesh thickness in designing filters that can target small particle sizes. Moreover, in the medical field, the performance of non-medical face masks has been evaluated, revealing that the construction of their filtration layers—including the thickness—plays a significant role in their ability to block submicron aerosols, which are crucial in mitigating respiratory exposure during health crises like the COVID-19 pandemic. By considering these factors, industries can enhance filtration systems to meet the growing demands of environmental and public health challenges.

When considering the optimal filtration performance of fine mesh materials, evaluating the impact of mesh opening patterns is paramount. Different opening shapes and sizes fundamentally influence the flow of fluids and the retention of particulates. For instance, a fine mesh with uniformly distributed openings can provide a consistent filtration rate, effectively capturing small particles while allowing larger flow volumes. Conversely, variations in mesh patterns can lead to uneven distribution, which may result in clogs or reduced efficiency over time.

Moreover, the choice of mesh opening patterns can also affect the cleaning and maintenance of the filtration system. A mesh designed with larger openings at intervals can facilitate easier passage and removal of trapped debris, enhancing the longevity of the filter. On the other hand, intricate patterns may require more frequent maintenance but could be crucial for applications where even minor particulates are detrimental. Therefore, meticulously assessing how various mesh patterns impact both filtration efficiency and maintenance requirements can guide users towards selecting the most suitable fine mesh for their specific needs.

| Tip | Description | Mesh Opening Size (µm) | Filtration Efficiency (%) | Applications |

|---|---|---|---|---|

| Tip 1 | Choose the right mesh size based on material particle size. | 100 | 85 | Water purification |

| Tip 2 | Consider opening patterns that support optimal flow rates. | 200 | 78 | Chemical processing |

| Tip 3 | Evaluate the durability of the mesh material under operating conditions. | 50 | 90 | Food processing |

| Tip 4 | Analyze the cleaning and maintenance requirements. | 150 | 82 | Wastewater treatments |

| Tip 5 | Investigate compatibility with the filtered substance. | 75 | 95 | Pharmaceutical production |

| Tip 6 | Assess the cost vs. longevity and performance balance. | 120 | 80 | Mining industry |

| Tip 7 | Collaborate with suppliers for tailored solutions. | 90 | 88 | Oil and gas sector |

Maintaining a fine mesh filter is crucial for ensuring its longevity and optimal filtration efficiency. Regular cleaning is one of the best practices to extend the lifespan of your mesh. Depending on the application, the frequency of cleaning may vary, but it is essential to remove any accumulated debris and contaminants that can hinder performance. Utilizing the right cleaning tools, such as soft brushes or gentle rinsing techniques, helps preserve the integrity of the mesh without causing damage.

Maintaining a fine mesh filter is crucial for ensuring its longevity and optimal filtration efficiency. Regular cleaning is one of the best practices to extend the lifespan of your mesh. Depending on the application, the frequency of cleaning may vary, but it is essential to remove any accumulated debris and contaminants that can hinder performance. Utilizing the right cleaning tools, such as soft brushes or gentle rinsing techniques, helps preserve the integrity of the mesh without causing damage.

Another key aspect of maintenance involves proper storage when the fine mesh is not in use. Elevating the mesh to prevent contact with dirt or potential contaminants and storing it in a dry, clean environment can significantly contribute to its durability. Additionally, be mindful of the operating conditions; excessive heat or pressure can degrade the mesh materials over time. By adhering to these best practices, you can ensure your fine mesh filter remains effective and reliable for all your filtration needs.