No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

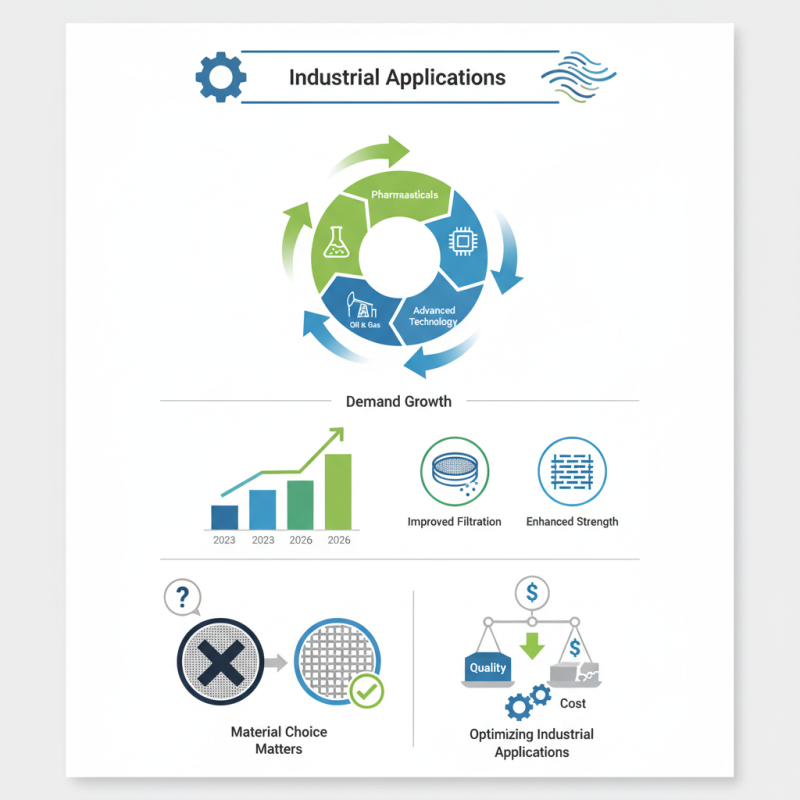

In the evolving landscape of industrial applications, Fine Mesh Metals are gaining traction. Reports by the Global Metal Market indicate a steady demand for these materials, projected to grow by 5% annually through 2026. Industries are increasingly adopting fine mesh solutions for their unique properties, such as improved filtration and enhanced strength.

The versatility of Fine Mesh Metals is notable. They are vital in sectors ranging from pharmaceuticals to oil and gas. For instance, in the food industry, these materials ensure safety and quality through effective separation processes. However, many users still overlook the importance of mesh size and material choice. This oversight can lead to inefficiencies and increased costs.

While advancements in technology enhance the durability and performance of Fine Mesh Metals, challenges remain. The balance between cost and quality often leads to compromises during production. Some businesses tend to use cheaper alternatives, risking product integrity. Thus, understanding the nuances of Fine Mesh Metals is crucial for optimizing industrial applications.

Fine mesh metals have become essential in various industrial applications. Their versatility allows for filtration, separation, and support structures in many sectors. Industries like pharmaceuticals, food processing, and aerospace greatly benefit from their unique characteristics. Reports indicate that the global fine mesh metal market is projected to grow at a CAGR of 5.3% from 2021 to 2027.

One popular use of fine mesh metals is in filtration systems. They can effectively filter out contaminants while optimizing fluid flow. For instance, a typical stainless steel mesh can trap particles as small as 10 microns. This level of precision is critical in maintaining product integrity in the pharmaceutical sector. However, sourcing high-quality fine mesh materials often presents challenges.

Another promising application involves structural elements in demanding environments. Fine mesh metals provide both strength and lightweight properties, making them ideal for aerospace components. Data shows that using fine mesh structures can reduce weight by up to 25%, improving fuel efficiency. Yet, manufacturers must reflect on potential weaknesses in their designs. A finer mesh might lead to reduced durability under extreme conditions. Balancing strength and weight remains a crucial consideration in the industry.

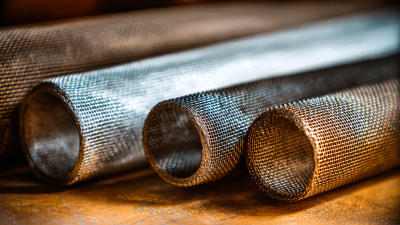

Fine mesh metals are gaining traction in various industrial applications due to their unique properties. They offer excellent filtration, precise separation, and durability. For instance, stainless steel meshes are favored for their corrosion resistance. Copper mesh is known for its superior conductivity and antimicrobial properties, making it ideal for electrical applications and medical environments.

In 2026, the demand for lightweight and strong materials is expected to grow. Fine mesh metals can meet this need, but they come with challenges. Manufacturing inconsistencies might occur, leading to variations in performance. Some meshes might not hold up in extreme conditions. Thus, users must carefully evaluate the application environment. Experimental testing is crucial to ensure the right mesh is selected.

Integrating fine mesh metals requires an understanding of their properties. Some meshes are too elastic, while others might be too rigid. This balance is essential for achieving optimal performance. In certain applications, gaps in the mesh may lead to inefficiencies. It's worth pondering if the anticipated benefits align with these potential drawbacks.

In industrial applications, fine mesh metals play a crucial role. They serve various purposes, such as filtration, sorting, and structural support. Stainless steel is popular due to its durability and resistance to corrosion. It’s commonly used in food processing and pharmaceuticals, where sanitation is key.

Another notable type is aluminum mesh. Lightweight and versatile, it often finds use in the automotive and aerospace industries. However, its lower strength compared to steel means it must be selected wisely. There are challenges in balancing weight with stability.

Bronze mesh is known for its conductivity and aesthetic appeal. It's frequently used in architectural applications and artistic installations. But, its cost can be a barrier for some projects. Selecting the right fine mesh metal requires careful consideration of these factors to achieve optimal results.

In the realm of industrial applications, fine mesh metals play a critical role. The demand for advanced filtering solutions has surged. Innovations in materials and manufacturing techniques are crucial. Recent trends show an inclination towards sustainability in production. Companies are seeking eco-friendly sources and processes. This is where future innovations will take shape.

There is an ongoing exploration of alloy compositions, enhancing strength while minimizing weight. New production technologies, such as additive manufacturing, are gaining traction. These methods could revolutionize how fine mesh metals are created. However, they also pose challenges. The quality of materials must be consistent, yet many manufacturers struggle to achieve this. The balance between cost-effectiveness and advanced technology is delicate.

The landscape is evolving rapidly, but not without hurdles. Intellectual property issues often arise during innovation. Many in the industry worry about the accessibility of cutting-edge techniques. Training skilled workers in these new methods remains a pressing need. As the market shifts, ongoing research and collaboration will be essential for progress. Fine mesh metals hold promise, but there is much to navigate.

When selecting fine mesh metals for industrial applications, there are several factors to consider. The material's corrosion resistance is crucial. For example, specific environments may expose metals to harsh chemicals. Choosing the wrong material can lead to rapid degradation and costly replacements. Analyzing the specific environment is vital to ensure longevity.

Another key consideration is the mesh size. This impacts both filtration efficiency and flow rates. A finer mesh can provide better filtration but may reduce flow. In high-demand applications, this balance is tricky. It’s important to understand the application’s needs thoroughly. Sometimes, we may overlook the impact of mesh size on overall performance.

Lastly, the manufacturing process of the mesh itself matters. The methods used can affect the consistency and strength of the final product. Inconsistent production could lead to unpredictable outcomes. Quality control is essential but often gets overlooked. Reflecting on these details can lead to better decisions and improved operational efficiency.

| Metal Type | Mesh Size (microns) | Tensile Strength (MPa) | Corrosion Resistance | Application Areas |

|---|---|---|---|---|

| Stainless Steel | 50 | 520 | High | Food Processing, Chemical |

| Aluminum | 100 | 300 | Moderate | Aerospace, Automotive |

| Brass | 80 | 250 | Moderate | Electrical Components, Plumbing |

| Nickel Alloy | 30 | 600 | Very High | Aerospace, Marine |

| Cooper | 150 | 210 | Low | Electrical Wiring, Electronics |