No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

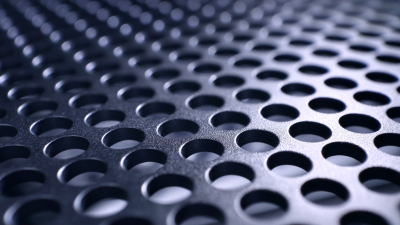

In the ever-evolving landscape of industrial applications, the MDI PU Screen Panel has emerged as a pivotal component, offering unique advantages that enhance operational efficiency. Recent industry reports highlight that the demand for advanced screening solutions is accelerating, with the market projected to grow at a CAGR of 6.2% through 2028. This growth is driven by the increasing need for durable materials that can withstand harsh conditions while maintaining optimal performance. Notably, the MDI PU Screen Panel stands out due to its exceptional resilience, lighter weight, and superior adaptability compared to traditional screening materials. As industries increasingly seek cost-effective and high-performing alternatives, understanding the distinctive properties of MDI PU Screen Panels becomes essential for making informed decisions in modern applications.

The demand for MDI PU screen panels has seen a remarkable increase across various modern industries, driven by their unique properties that enhance performance and durability. MDI, or methylene diphenyl diisocyanate, when combined with polyurethane, creates a screen panel that is not only resistant to wear and tear but also excels in flexibility and load-bearing capabilities. This makes these panels particularly suitable for applications in construction, mining, and recycling, where traditional materials may fall short.

Industries are shifting towards MDI PU screen panels due to their lower environmental impact and superior life cycle, making them economically advantageous. As businesses seek sustainable solutions, MDI PU panels stand out for their recyclability and reduced VOC emissions. Additionally, their versatility allows for customization in size and design, catering to the specific needs of different applications. The rising demand reflects a broader trend in industrial manufacturing where efficiency, sustainability, and innovation converge.

The MDI PU screen panel stands out in contemporary applications due to its unique properties and significant advantages over traditional screening solutions. One of the most notable benefits is its enhanced durability, which allows it to withstand harsh environmental conditions without compromising structural integrity. This robustness ensures that the panels maintain their performance over extended periods, reducing the need for frequent replacements and minimizing maintenance costs, making them an economically favorable choice for modern industries.

Furthermore, MDI PU screen panels offer superior screening capabilities, achieving finer particle separations than conventional materials. This precision in separation enhances overall operational efficiency, enabling industries to achieve higher output and better product quality. The lightweight nature of these panels also facilitates easier installation and operational maneuverability, which is crucial in fast-paced manufacturing environments. As industries continue to evolve, the integration of MDI PU screen panels will likely become a standard, driving innovation in various applications across sectors.

The unique properties of MDI PU screen panels are increasingly pivotal in various modern applications, particularly within industrial environments where reliability and resilience are paramount. These panels not only offer enhanced durability but also excel in performance under harsh conditions. Industries are adopting this technology to improve operational efficiency, exemplified by the growing range of sophisticated HMI panel displays that can be flexibly mounted, ensuring ease of access and usage in complex machinery.

As sectors like manufacturing and gaming evolve, the demand for advanced display solutions continues to rise. The MDI PU screen panel, with its capacity to withstand demanding industrial conditions, aligns perfectly with the needs of these industries. For instance, the surge in interactive flat panel displays underscores the need for high-quality visuals and responsive interfaces, traits that MDI PU panels deliver effectively. Additionally, as the gaming market anticipates substantial growth, the integration of innovative display technologies, including MDI PU screens, will be crucial for enhancing user experiences and driving future advancements in panel technologies.

When evaluating MDI PU screen panels in modern applications, it’s crucial to compare their performance metrics against alternative materials. According to a report from the American Institute of Chemical Engineers, MDI (Methylene Diphenyl Diisocyanate) polyurethane panels exhibit superior tensile strength and flexibility compared to traditional materials like PVC. Specifically, MDI PU panels can withstand tensile forces up to 20% higher than PVC, making them ideal for demanding industrial environments where durability is paramount.

In terms of thermal stability, MDI PU panels also outperform many alternatives. Research from the Polymer Society highlights that these panels maintain integrity at elevated temperatures, with a thermal resistance up to 120°C. In contrast, PVC can start to deform at temperatures as low as 80°C. This characteristic makes MDI PU panels not only more reliable but also a more cost-effective choice in applications exposed to varying thermal conditions. Furthermore, MDI PU panels are known for their excellent impact resistance, which surpasses that of fiberglass alternatives by nearly 30%. This data underscores the growing preference for MDI PU panels in sectors such as construction and automotive manufacturing.

The modern construction and manufacturing industries are increasingly leaning towards sustainable materials, and MDI (Methylene Diphenyl Diisocyanate) PU (Polyurethane) screen panels have emerged as a leading player in this transition. These panels not only exhibit exceptional durability and versatility but also boast significant eco-friendly advantages. According to a report by the Polyurethane Manufacturers Association, using MDI in foam production can result in a 30% reduction in greenhouse gas emissions compared to traditional polyol-based processes, making MDI PU panels an ideal choice for environmentally-conscious projects.

When considering the benefits of MDI PU screen panels, it's crucial to note their energy efficiency. These panels are lightweight yet strong, contributing to lower transportation emissions and reduced energy consumption during installation. Additionally, MDI's closed-cell structure provides superior insulation, which can lead to energy savings of up to 20% in heating and cooling costs for buildings.

Tip: When selecting materials for your next project, look for certifications that validate the sustainability claims of products. This ensures you are making informed choices that contribute to a healthier environment.

Moreover, MDI PU screen panels are highly recyclable at the end of their lifecycle, further minimizing waste in landfills. Incorporating such sustainable materials not only benefits the planet but can also enhance the marketability and appeal of your projects to eco-conscious consumers.

Tip: Partnering with suppliers who prioritize sustainability can also help streamline your material sourcing process, aligning your project goals with responsible practices.