No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

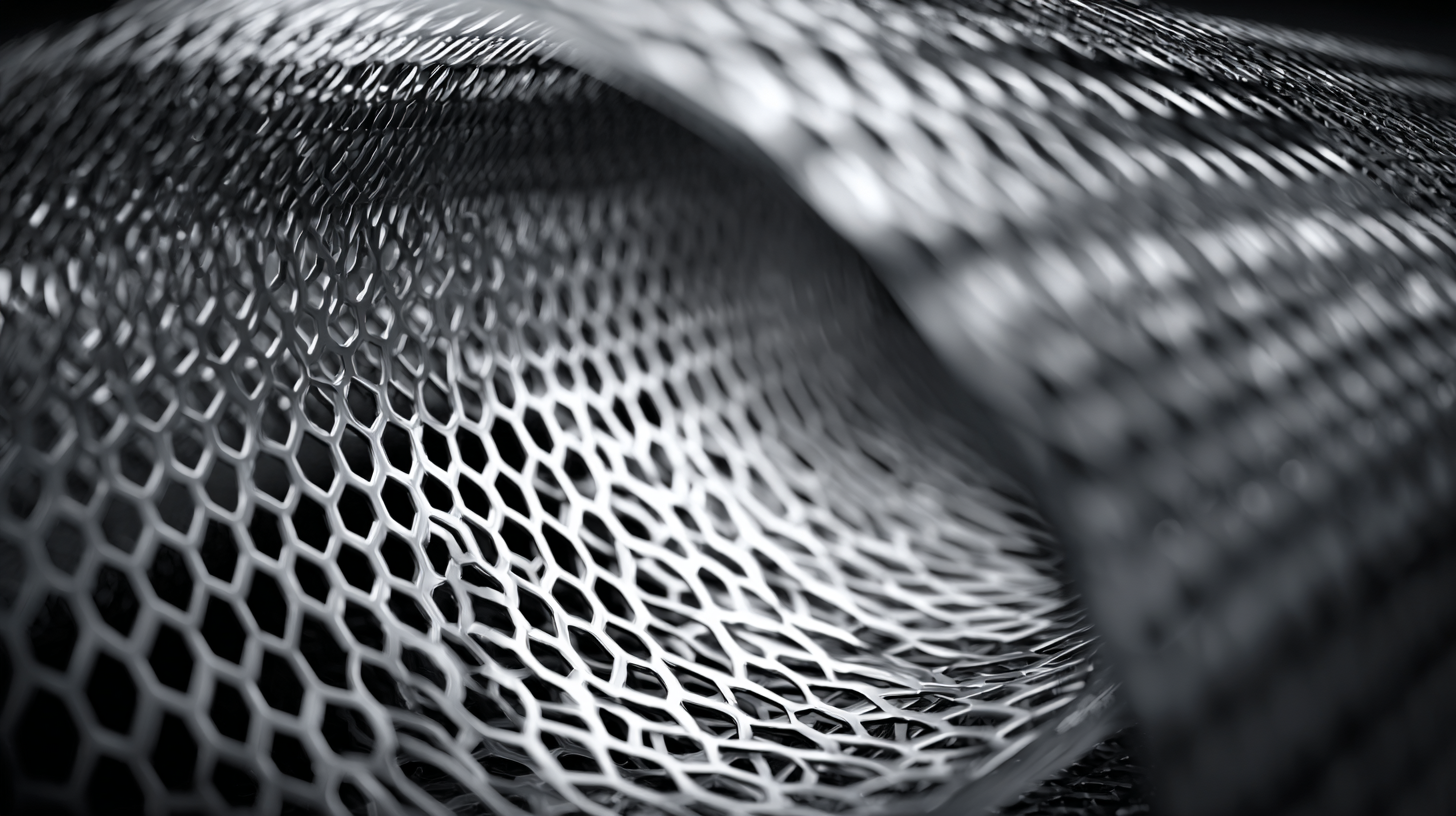

The versatility of Fine Mesh Metals in modern engineering applications has garnered significant attention in recent years, driving advancements across various industries. According to a report by MarketsandMarkets, the fine mesh metals market is projected to reach $3.2 billion by 2026, growing at a CAGR of 5.3% between 2021 and 2026. This growth is propelled by the increasing demand for lightweight, durable materials that can withstand high temperatures and corrosive environments, particularly in sectors such as aerospace, automotive, and filtration systems. Fine Mesh Metals, with their precise openings and high strength-to-weight ratios, present unique advantages in applications ranging from industrial filtration to protective screens in electronics.

As engineers and designers seek innovative materials to enhance performance and efficiency, understanding the multifaceted applications of Fine Mesh Metals becomes crucial in creating competitive and sustainable solutions in the rapidly evolving landscape of modern engineering.

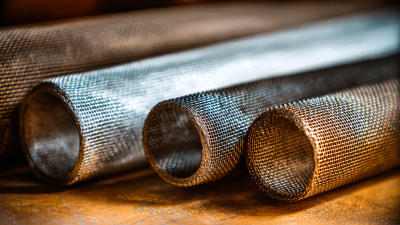

Fine mesh metals are increasingly recognized for their unique properties that make them essential in modern engineering applications. Characterized by small openings and high tensile strength, these materials provide excellent filtration capabilities, allowing for efficient separation of particles in various industries, including chemical processing and pharmaceuticals. Their lightweight nature combined with durability makes them ideal for applications where low weight and high performance are critical, such as in aerospace and automotive design.

One of the notable benefits of fine mesh metals is their versatility in design. Engineers can fabricate these materials into complex shapes, which can enhance their functionality without compromising structural integrity. Additionally, fine mesh metals can be coated or treated to improve corrosion resistance, making them suitable for use in harsh environments. Their ability to withstand extreme temperatures while maintaining stability further cements their role in innovative engineering solutions, providing both reliability and efficiency in critical applications.

Fine mesh metals have found diverse applications across various industries, primarily due to their unique mechanical properties and versatility. One noteworthy area of exploration is the aerospace sector, where the effect of mesh size on the mechanical performance of stainless-steel wire mesh and glass fiber reinforced hybrid composites is under study. The adaptation of fine mesh metals in these composites enhances strength and weight efficiency, critical for aerospace engineering. This highlights the ongoing innovation to meet the demanding requirements of modern aviation technologies.

In addition, the industrial sector benefits significantly from custom-fabricated mesh solutions for high-performance screening applications. Companies are increasingly adopting welded wire mesh panels, reflecting a substantial market growth driven by heightened demands in construction, automotive, and manufacturing industries. The versatility of fine mesh metals, including their capability to separate and filter materials efficiently, underscores their integral role in contemporary engineering solutions, paving the way for advancements in material science and application engineering across multiple sectors.

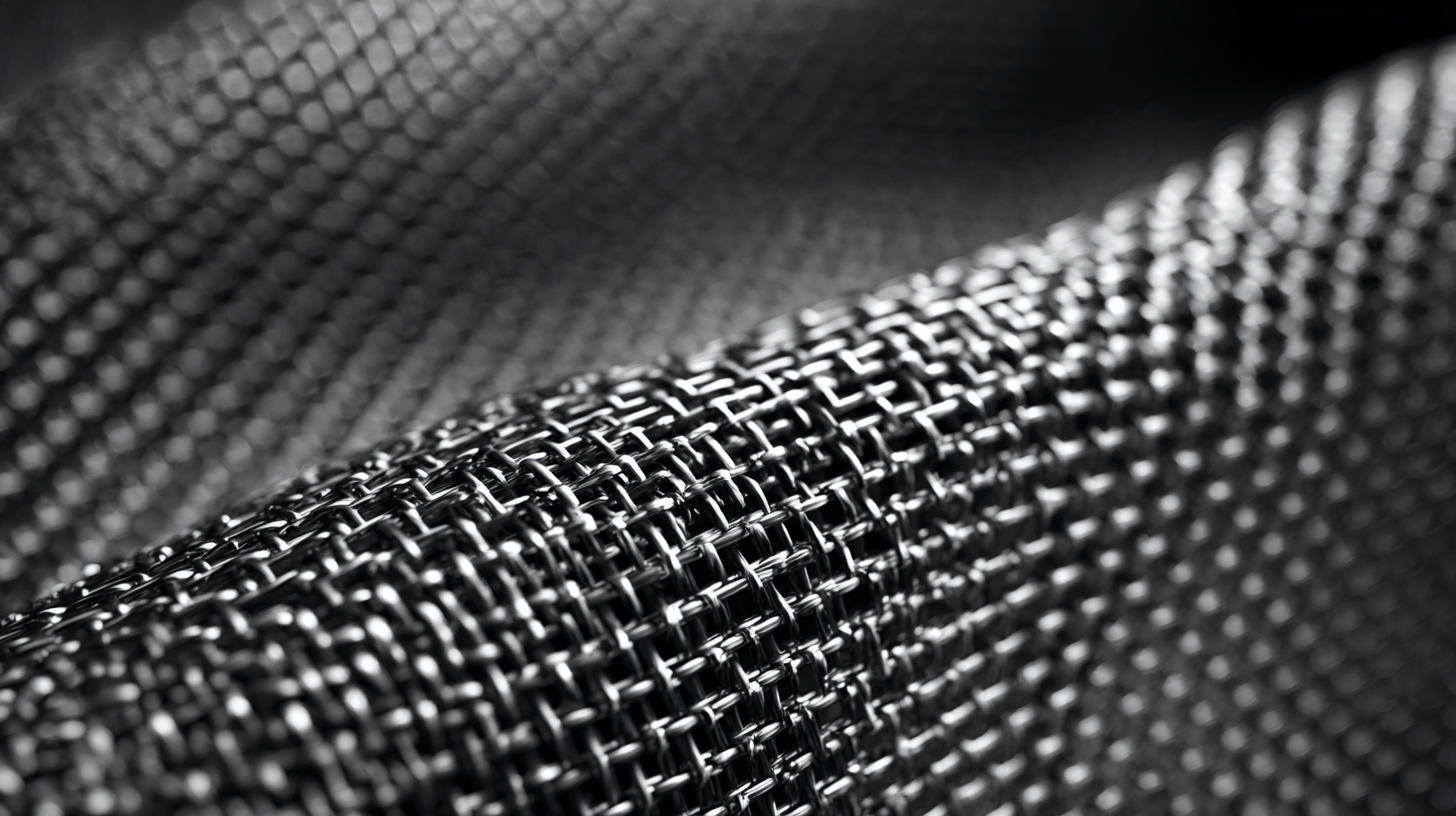

When selecting the right type of fine mesh metal for your engineering needs, it’s essential to consider factors such as the material’s properties, mesh size, and intended application. Common materials used in fine mesh metals include stainless steel, aluminum, and copper, each offering unique advantages. For instance, stainless steel provides excellent corrosion resistance, making it ideal for applications in harsh environments, while aluminum is lightweight and suitable for industries requiring reduced weight without sacrificing strength.

**Tips:** Before making a selection, assess the environmental conditions your project will face. Consider factors like temperature fluctuations and exposure to chemicals. Additionally, evaluate the required flow rate and filtration efficiency, as these parameters will significantly influence the performance of the fine mesh metal.

Another vital aspect to consider is the manufacturing process. Specific applications may require intricate designs or custom sizes. Understanding the available fabrication techniques—such as welding, stamping, or weaving—can help ensure you choose a fine mesh metal that aligns perfectly with your engineering specifications. Always communicate your requirements with suppliers to explore the best options tailored to your project's needs.

| Mesh Type | Material | Wire Diameter (mm) | Opening Size (mm) | Applications |

|---|---|---|---|---|

| Plain Weave Mesh | Stainless Steel | 0.25 | 0.5 | Filtration, Screen Manufacturing |

| Dutch Weave Mesh | Copper | 0.18 | 0.3 | Chemical Processing, Oil Filtration |

| Twilled Weave Mesh | Bronze | 0.20 | 0.4 | Architectural Uses, Decorative Applications |

| Lenticular Mesh | Aluminum | 0.15 | 0.2 | Noise Reduction, HVAC Applications |

| Woven Wire Mesh | Carbon Steel | 0.30 | 0.6 | Mining, Sand and Gravel Screening |

Innovative techniques for fabricating fine mesh metals are revolutionizing modern engineering applications. Recent advancements in 3D printing technology support the creation of complex metal structures, enabling the use of fine mesh metals in diverse applications such as construction, biomedical devices, and electronics. Notably, researchers have developed robotic systems integrated with metal mesh for concrete construction, enhancing accuracy and efficiency in building practices. This approach not only improves structural integrity but also allows for innovative designs that were previously unattainable.

Additionally, the emergence of hydrogel-based metal additive manufacturing techniques is paving the way for better alloy designs. These methods facilitate the production of metallic components with meticulously controlled shapes and compositions, demonstrating the interplay between fine mesh metals and modern manufacturing processes. The emerging field of 3D-printed customized medical devices, such as biodegradable vascular stents, underscores the versatility of fine mesh metals in sectors requiring precision and adaptability. As these technologies evolve, the potential applications for fine mesh metals in engineering continue to expand, offering exciting opportunities across various industries.

Fine mesh metals have gained significant attention in modern engineering applications due to their unique properties and versatility. Evaluating the performance of these materials is crucial to ensure they meet stringent industrial standards. According to a report by the Materials Research Society, fine mesh metals exhibit enhanced mechanical strength and corrosion resistance, making them suitable for various applications such as filtration, automotive, and aerospace industries. For instance, stainless steel mesh, with a typical aperture size of 200 microns, demonstrates performance stability even under extreme conditions, leading to higher efficiency and durability in engineering solutions.

Quality control mechanisms are vital in maintaining the integrity of fine mesh metals. Rigorous testing methods, including tensile strength tests and fatigue tests, have shown that fine mesh structures can withstand considerable loads without compromising their integrity. The International Journal of Engineering Materials reported that metal meshes subjected to comprehensive quality assessments displayed a significant reduction in failure rates, down to less than 1% in critical applications. This data underscores the importance of quality control in maximizing the operational lifespan and reliability of fine mesh metals, ultimately contributing to safer and more efficient engineering outcomes.