No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

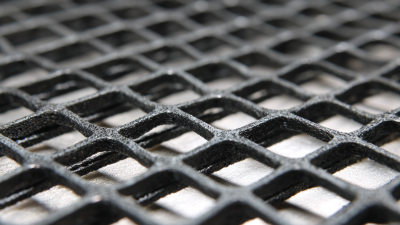

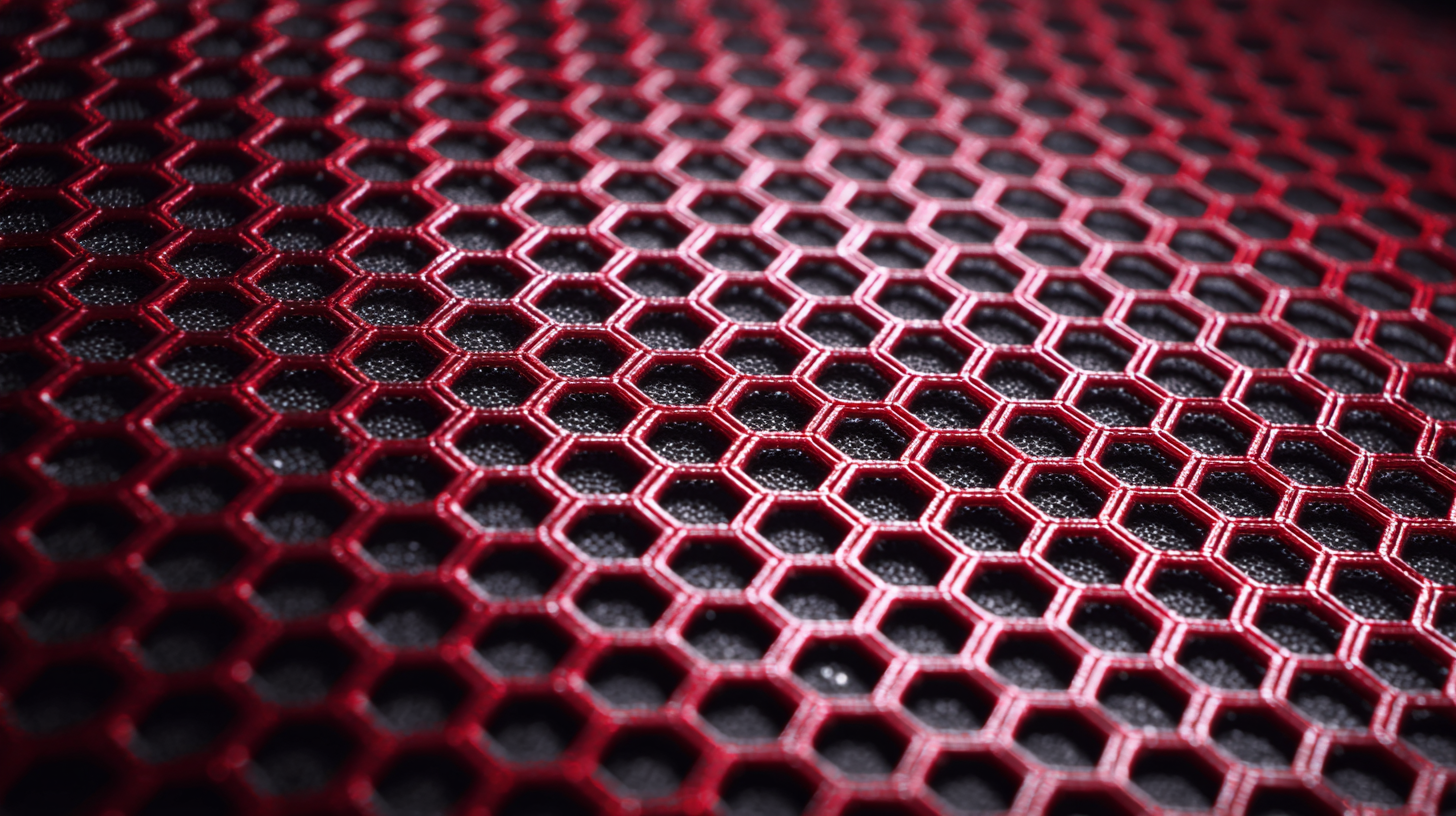

The versatility of Urethane Screen Mesh has made it an integral component across various industrial applications, ranging from mining and aggregate processing to wastewater treatment. According to a report by MarketsandMarkets, the global market for screening media, including urethane products, is expected to grow significantly, driven by the increasing demand for efficient and durable filtering solutions.

Urethane Screen Mesh is renowned for its exceptional wear resistance, flexibility, and high load-bearing capacity, allowing industries to enhance operational efficiency while minimizing downtime. As manufacturers seek innovative solutions to improve productivity and reduce maintenance costs, the adoption of Urethane Screen Mesh will likely continue to expand, solidifying its position as a preferred choice in diverse sectors.

In this article, we will explore the multifaceted applications of Urethane Screen Mesh and its transformative impact on industrial processes.

Urethane Screen Mesh is renowned for its exceptional wear resistance, flexibility, and high load-bearing capacity, allowing industries to enhance operational efficiency while minimizing downtime. As manufacturers seek innovative solutions to improve productivity and reduce maintenance costs, the adoption of Urethane Screen Mesh will likely continue to expand, solidifying its position as a preferred choice in diverse sectors.

In this article, we will explore the multifaceted applications of Urethane Screen Mesh and its transformative impact on industrial processes.

Urethane screen mesh has gained significant attention in various

industrial sectors due to its distinct features and advantages.

Characterized by exceptional abrasion resistance,

urethane mesh can withstand heavy usage, making it suitable for high-impact applications.

According to a recent report by the Industrial Fabrics Association International,

urethane mesh durability can exceed that of traditional materials by as much as 25%,

leading to reduced replacement costs and less downtime in industrial processes.

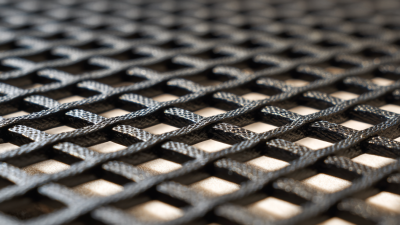

In addition to its durability, urethane screen mesh offers superior flexibility and adaptability, allowing it to conform to various shapes and sizes without losing structural integrity.

This versatility is pivotal in industries such as mining and aggregate, where materials can vary widely in both size and type.

A study from the International Journal of Industrial Technology highlights that utilizing urethane screen mesh can enhance

screening efficiency by as much as 30%, optimizing material separation processes and improving overall productivity.

These key features and associated benefits significantly elevate urethane screen mesh as a

vital component in contemporary industrial applications.

Urethane screen mesh has gained significant recognition in various industrial applications due to its durability, flexibility, and resistance to wear and tear. One of its primary uses is in the mining industry, where it effectively separates materials while minimizing blinding and pegging. The mesh's ability to endure harsh environments while maintaining performance makes it an invaluable asset in this sector.

In addition to mining, urethane screen mesh is widely employed in the construction and recycling industries. It is often used in aggregate screening and for sorting metals and plastics. The mesh’s versatility allows it to handle different materials with varying sizes and weights seamlessly.

**Tips:** When selecting urethane screen mesh for your application, consider the specific size and type of materials you will be processing. Ensure that the mesh dimensions align with your operational needs to optimize performance. Regular maintenance and inspection can also prolong the lifespan of the urethane screen mesh, ensuring consistent productivity in your industrial processes.

When selecting the right urethane screen mesh for your industrial needs, it’s essential to consider factors such as mesh size, tensile strength, and abrasion resistance. According to a report from Global Market Insights, the global urethane screen market is projected to reach approximately $300 million by 2027, driven largely by its durability and versatility in various sectors, including mining, food processing, and recycling.

A tighter mesh size can enhance sifting efficiency, making it ideal for applications requiring precision. For instance, a 40 mesh screen effectively retains fine particles, crucial in the production of high-quality aggregates.

Another critical aspect to evaluate is the tensile strength of the urethane material. Research indicates that urethane mesh can have tensile strengths exceeding 5,000 psi, making it suitable for applications that involve high-impact materials. Selecting a urethane mesh with the right balance of flexibility and toughness is vital to maximize productivity while minimizing wear and tear on the equipment.

Additionally, industries utilizing urethane screens report a significant reduction in maintenance costs—up to 30%—due to the material's inherent resistance to wear and chemicals. This statistic underscores the importance of making an informed choice tailored to specific operational requirements.

When it comes to installing urethane screen mesh in various industrial applications, proper techniques can significantly enhance performance and durability. First and foremost, ensuring a clean and dry installation surface is crucial. Any debris or moisture can compromise the adhesion of the mesh, leading to premature wear or failure. Use a suitable adhesive specified for urethane materials to guarantee a strong bond. Additionally, it is essential to prepare the mesh by cutting it to fit the desired dimensions, taking care to avoid sharp edges that could lead to damage during installation.

Moreover, employing the right tension during installation is vital. Over-stretching can cause the urethane mesh to become brittle and less effective, while under-tensioning might lead to sagging, impacting the screening process. It's advisable to use tensioning tools that can help distribute the tension evenly across the mesh. Regular inspections post-installation can further ensure longevity; addressing any signs of wear or damage early on can prevent costly downtime and maintain effective operations across various industries.

To ensure the longevity of urethane screen mesh, effective maintenance practices are crucial in maximizing its performance across various industrial applications. Regular inspections should be conducted to identify any signs of wear, such as tears or fraying, which may compromise the integrity of the mesh. According to a recent report from the Industrial Fabrics Association International, proper maintenance can extend the life of urethane mesh by up to 30%, significantly reducing the need for frequent replacements and thereby decreasing operational costs.

In addition to regular inspections, cleaning urethane screen mesh is essential for maintaining its functionality. Accumulation of debris can lead to clogging, reducing throughput efficiency. Industry experts recommend a gentle washing procedure using non-corrosive cleaning agents to avoid damaging the mesh material. Furthermore, ensuring that the mesh is installed correctly and is free from undue tension will help prevent premature wear. Adhering to these maintenance practices not only enhances the durability of urethane screen mesh but also contributes to optimal operational performance in demanding industrial environments.